Well reinforced concrete rings: parameters and specifications

A well in any country plot that does not have a central water supply line is considered to be the most important mechanism that ensures the supply of living space with water. For performance of a well various building materials are used. But mainly for the manufacture of such a design is used reinforced concrete rings with high technical characteristics.

Special features

The use of precast concrete in industrial and civilian construction allows to reduce the time of delivery of objects, while increasing productivity.One of the most common building materials are well concrete products.

The areas of their use are various:

- drinking water well;

- purification facility;

- drainage well;

- sewage system

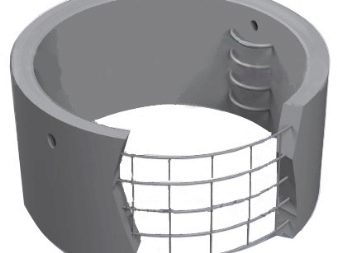

This structure is a construction of a metal frame and concrete.

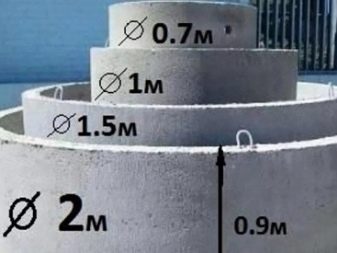

The height of the rings can vary from 10 to 90 centimeters, and the diameter from 70 cm to 2 meters. According to GOST, cement M200-500 should be used for the manufacture of such structures. The products of these spectra are subject to labeling. On a stable ground, you can mount a well of the rings, which are made with your own hands. It is necessary to purchase concrete with the marking M200, which is made from cement M400 or M500. Pure quartz sand is used as a filler.

Ingredients that contribute to reducing the shrinkage of the solution are necessarily introduced into this mixture. Self-made variations are not recommended for complex structures.

Reinforced concrete structures have such advantages as:

- strength and durability;

- 100% tightness of the joints;

- simple installation;

- reasonable price of products.

The only downside is weight.To install the product will need help lifting equipment. The manufacture of various types of rings has some nuances. Not all models can be reinforced. But products with a frame made of steel are the most durable and resistant to various loads.

Production models of rings are reinforced with a special technology of special pressing with the use of vibratory plants. This procedure gives the products excellent shrinkage. Due to the vibrations, air bubbles are removed from the solution, which are capable of destroying the structure.

Regulatory requirements

GOST-8020-90 determines the qualities characteristic of RC rings. It describes the labeling, scope, parameters of standardized structures. Strength indicators of various grades of concrete used for casting rings are specified in GOST 10180.

GOST 10060 contains information about the frost resistance of the product, and GOST 12730 - about the coefficient of water resistance. Reinforced concrete structures differ not only in parameters, but also in marking. It is used to separate the appointment of products.

Very popular are several products with abbreviations such as:

- KO - these are the reference models used for the lower area of the entire system;

- KFK - it is the concrete goods used for construction of branches of water or sewer system;

- CLA - These are models that are made for urban water runoff and sewer lines.

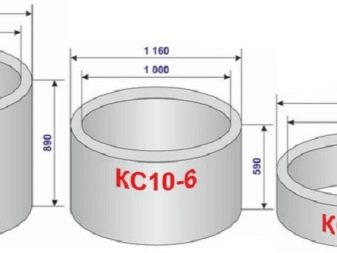

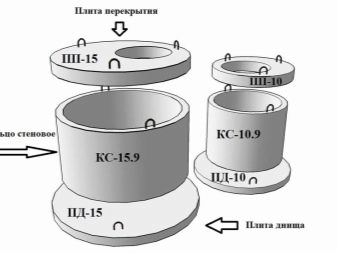

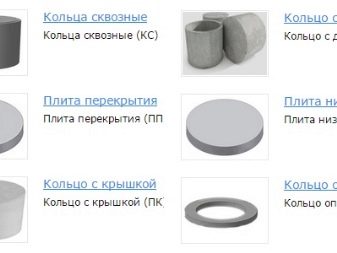

In addition to the lettering, the marking indicates the numbers. They denote the height and diameter of the structure. RC products are equipped with additional elements, such as overlapping of the bottom. In this case, the plate is marked PP or PC. The plates intended for a bottom are designated PD.

Such structures give a tight structure. They are installed above and below to protect the structure from the ingress of groundwater. In drinking wells stoves are used to protect against various contaminants and from groundwater.

To choose reinforced concrete rings for a well is quite difficult. To avoid installation difficulties, these structures are labeled. They indicate the desired values, such as the height and diameter of the product. As well as marking allows you to know the cost of a particular product.

Dimensions

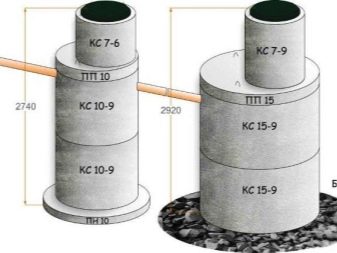

Before you buy RC rings, you need to know the volume of waterconsumed by homeowners. In addition to rings, other structures are used in communication systems of this type. For them, the parameters of reinforced concrete structures are selected individually, taking into account the calculations of the functioning of the structure. These types include complementary and auxiliary elements. The sizes of reinforced concrete rings can be very different. But there are well-established standard sizes, which produce most of the designs. At the same time height of products varies from 10 cm to 1 meter.

The main parameters of the facilities include the following:

- height. This parameter can vary from 10 to 180 cm. The higher the structure, the more difficult it will be to install. The most in demand products having a height of from 50 to 90 cm;

- diameter inside. It ranges from 70 to 200 cm, it is selected depending on the type of the future structure, as well as the volume of liquid consumed. The optimal parameters for a drinking well are from 90 to 160 cm. Large facilities are used for the construction of sewer and viewing structures;

- Wall thickness. It can be from 8 to 12 centimeters.

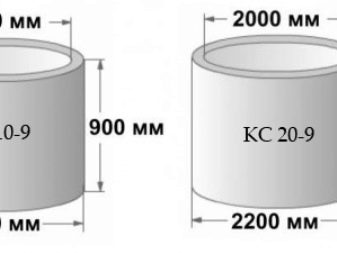

Often found rings with such dimensions as:

- COP 20.9 (2 meters) - volume 2.83 m³;

- COP 15.9 (1.5 m) - 1.59 m³;

- COP 10.9 (1 meter) - 0.71 m³.

Kinds

Reinforced concrete structures vary in type of construction into several types.

- Auxiliary. Such concrete rings are made to order, when non-standard dimensions of the product are necessary. Additional and support rings are used in the installation of complex objects, for example, in the construction of the well mouth when drainage systems are installed. These rings can be standardized or square.

- Wall. Such rings do not have in the presence of auxiliary fixing special elements. They are mainly used for the construction of the neck. They are easy to install. It is enough to lay the products on top of each other, and seal the seams with concrete. The downside is the poor stability of the structure, with the slightest shear of the soil the product will collapse.

- With the bottom. Reinforced concrete structures with a finished waterproof bottom are used for the construction of sewer manholes, settling chambers, septic tanks. The bottom prevents the ingress of groundwater into the structure, as well as the infiltration of harmful substances into the soil layers.

- Base plates. They have a rectangular shape with a hole for the exit, which can be round or rectangular. They are closed with a metal hatch with a rounded shape or a rectangular drain grate.

The rectangular shape of the plate allows you to protect the structure from destruction. And also this form allows you to evenly distribute the load around the perimeter of the plate.

To the additional special elements belong the following:

- cover (slab) with a hole for the hatch, the diameter of which is 70 cm;

- hatch made of polymer building material or cast iron. Height varies from 70 to 120 cm;

- plug-in elements and sections are used to build new and dismantle old structures;

- the house is used for the outer part of the building, it is protected from the entry of debris and precipitation;

- the ladder is designed for quick access for special inspection, preventive actions and repair. A staircase is installed in the mine, its length is from 1 to 9 meters. Depending on the structure, it can be a drain, sewer, stepladder.

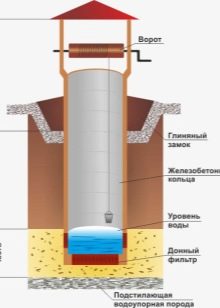

Installation

It is worth considering the variation of the construction of the well with the installation of concrete rings, since this method is very popular among owners of country sites.

The whole procedure of arranging the well is divided into stages such as:

- determining the location of the structure;

- excavation;

- installation work;

- waterproofing design;

- installation of the filtering layer;

- arrangement of the upper well area;

- decorative design of a well (if necessary).

Where to install the structure?

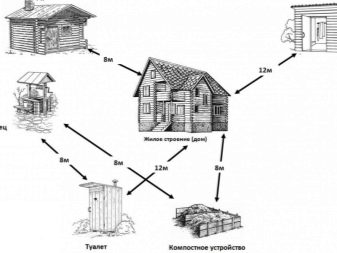

To begin with, it is necessary to exclude areas that are located near cesspools, drainage well, septic tanks. The distance between the installation and such structures should be at least 50 meters. And also the well should be located not less than 5 m from capital structures.

The main goal is to find a place where there is a second aquifer of groundwater, which is located as close as possible to the surface of the earth. The most accurate determination of the location is considered the method of exploration drilling, however, this method is quite time-consuming exercise, which not everyone can afford.

Basically, the search for aquifers is carried out in the early morning (5.00–6.00) or in the evening (18.00–19.00). It is worth paying attention to the lowlands, areas with an increased amount of dew, as well as places where fog gathers with a thick canvas. Previously, dowsing was used for these purposes.

Folk craftsmen unmistakably pointed out a plot with a slingshot made of elongated spruce branches. She was held in her hands in an upright position, and in the place where the groundwater was located, the master felt the gravity of the main trunk of the slingshot to the surface of the earth.

Places with aquifers can be determined by water absorption. To do this, take building material, which has high rates of moisture absorption (crushed red brick). Such material is thoroughly dried and filled with an earthen vessel. This device is wrapped in a nonwoven fabric, weighed with the utmost accuracy to the gram. The filled vessel is buried in the ground to a depth of 0.5 meters and left for 24 hours. You can do this at several sites. A day later, you need to get the vessels and check how much moisture was absorbed by different vessels. An ideal place for digging a well will be where more moisture is collected.

But this method is quite difficult to apply yourself, if there is no specific skill and experience. This method can be used otherwise.It is necessary to make two identical L-shaped frames from metal wire. They need to be held freely in the hands of a short shoulder, slowly walking through the whole area. When approaching places with the location of the aquifers, they should be flipped or crossed.

Required materials and tools are as follows:

- shovels with sharp ends;

- cables or strong ropes for insurance;

- clay tanks;

- tripod;

- sand, gravel, crushed stone for the filter layer;

- concrete rings;

- connecting brackets;

- sealant for seams;

- durable wood boards for rolling rings.

Digging pit

In order to properly dig a hole under the device of a well of reinforced concrete rings, it is necessary to know the parameters of the device so that there will be no problems later. Dig a hole so deep that it exceeds the height of the ring in 1,5-2 meters. The diameter of the pit should exceed the size of the ring by 20 cm. This must be done in order to cover the rings from the outside with sand, gravel or rubble. And also it will be more convenient to lower the structure into the pit. The first ring is placed in the pit and digging inside the product.Under its own mass, it gradually descends, thereby making room for mounting subsequent rings. Dig a hole before the appearance of the aquifer of the soil.

If there is a possibility of renting special equipment, then they dig a hole immediately to the full depth. It is necessary to dig a hole in dry summer weather so as not to mix the melt water with the aquifer. The approximate depth of the aquifer is 5–10 meters.

Installing rings

After the pit is dug, you can proceed to the installation of rings. The rings are lowered to the bottom only after pumping out sand with liquid. When the first ring is mounted, 2–3 N-shaped connecting brackets are put on it so that the products do not slide down during installation. The joints of the rings are carefully lubricated with cement-sand mixture or liquid waterproofing. Otherwise, water will seep through. Also, this procedure will not allow the soil to crumble. The mounting of the rings is carried out in such a way that the extreme ring protrudes above the soil level by 20–30 centimeters.

The second method of immersion rings is carried out together with the digging of the pit. Initially, the foundation pit for the first ring is not drawn to its full height, so that the ring protrudes slightly above the ground. Further, the digging of the pit continues inside the ring.When the inner perimeter is dug, you can start taking out the soil from under the walls of 1 ring so that it falls. After the first ring is immersed, a second ring is installed on it, which is equipped with scraping mechanisms in advance. Further, the digging of the pit continues with the extraction of soil from under the first ring.

The installation of reinforced concrete rings can be performed both with a lifting machine and manually, rolling the products to the pit and turning them to the desired position.

Tripod application

Removing the soil at a depth of more than 3 meters is quite difficult. When the digging person plunged into the pit to a depth exceeding his height, one can proceed to the equipment of the tripod. This construction is installed above the pit. Between the two legs mounted shaft with a pulley. A rope, chain or cable of the required length is attached to the shaft. After that, the earth is lifted by a person who is on the surface.

Filter device at the bottom

When you get to the aquifer, do not rush to complete the digging of the pit. If water leaks out weakly, then you need to continue to dig until there is an intense influx of fluid. After that, water is pumped out with sand to find out where it comes from. When at least three aquifers are found, the installation of the water supply well can be completed on that day.

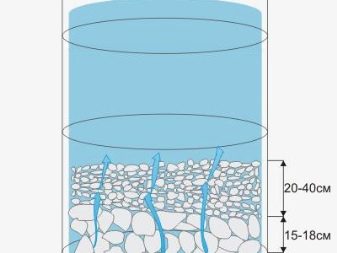

The next day, the pumped liquid and sand are pumped out to put a gravel and rubble filter on the bottom of the excavation. The total height of the filtering layer should be 30–40 cm. The initial 15–20 cm is the installation of stones to hold the sand mass, and the next 15–20 cm is gravel and crushed stone intended for detailed water purification.

Between stones and gravel it is necessary to lay a layer of geotextile, which should be slightly larger than the diameter of the ring. He is able to hold 90% of the sand mass, making the liquid cleaner. If the water enters slowly, it is necessary to remove the filter layer.

When the work on falling asleep biofilter is finished, you need to wait until the well is again filled with fluid. At this time, you can dig a trench for the installation of water pipes. Outside, concrete rings are covered with a pad of sand and gravelite. The last ring should be installed so that it protrudes 0.7–1 meter above the ground. After the construction of the well, you need to close it with a lid to prevent various debris from getting inside.

And it is also necessary to make a hole for ventilation, so that the building is ventilated.In the future, it will be possible to decorate the structure in the form of a house of various building materials. In order to prevent sediments from seeping through the ground, it is necessary to dig the soil (0.5–1 m wide, 0.5 m deep) near the rings all around the contour and fill it with a clay mass. Such a layer does not allow penetration of rain or talyovy fluid near the structure, thereby not destroying it.

Tips

The work of digging a well is very dangerous, therefore Security measures such as:

- when digging a hole, it is imperative to check the air quality by means of an open flame (a burning match or a candle). If the flame goes out, then work should stop. So that the dangerous gases disappear and a sufficient amount of oxygen enters, an open umbrella or blanket is lowered into the shaft several times;

- the working area must be fenced in order to prevent access to the pit for strangers and children;

- Do not stack excavated land near the mine, the minimum distance from the mine should be 3 meters. It would be better if there is an opportunity to immediately bring the earth to a safe distance;

- it is imperative to warn the excavator that the tools are lowered inside the mine;

- the person inside the mine must be in a protective helmet;

- Soil extraction containers must be firmly and securely attached to a rope or rope;

- lifting equipment must be equipped with a reliable brake and locking system.

Basically, special construction teams, which have their own professional equipment and tools, are engaged in digging the pit and installing reinforced concrete rings.

But if there is no possibility to hire such a brigade, then all the work must be carried out with extreme caution and all rules must be observed.

In the next video you will find the manufacture of a concrete ring for a well.