Choosing a polymer well

The polymeric well is a construction from composite materials, such as plastic and sand. If earlier a wooden blockhouse, brick or reinforced concrete was used for construction, then at present polymers are the optimal solution. Such a well is a prefabricated structure, which consists of rings (height of each 200 cm), bottom, cover and hatch. The upper ring is narrowed and, if necessary, a lid or hatch is installed on it.

Special features

Each person tries to choose material for building a well, which will be as resistant to external influences as possible. Its tightness is influenced by many factors - ground water, chemicals contained in them, temperature drops and much more. Modern polymer wells perfectly cope with this.

They are structures intended for the extraction of groundwater. The composite material in them is the basis of a particularly durable variety of plastic; a filler is added to it to impart various properties — elasticity, strength, resistance to temperature extremes (in this case, sand). As a rule, wells consist of eight rings, but their number can be increased or decreased. This allows you to mount them at any depth.

One of the features of this design is its weight. Polymer sand constructions are distinguished by the fact that they are much lighter than their counterparts, for example, from reinforced concrete. If the latter have an average weight of 500 kg, then the weight of the first reaches only 60 kg. This plus greatly facilitates transportation; a well can be lifted by two people without using special equipment.

Due to the very low weight installation is also possible to make their own.

Advantages and disadvantages

The low weight of polymer wells is not only their feature, but also a significant advantage. The small dimensions of the rings (they are not more than 1.1 m in diameter) also facilitate transportation, as they easily fit into a regular passenger car.

But if you continue to compare them with reinforced concrete, you can still notice a number of advantages. For example, tightness. Since the structural elements of composite materials are fastened along a system of grooves, due to this, they are joined as closely as possible, and they are almost not afraid of ground movement. This means that the connection absolutely does not let water through and does not erode; for insurance, you can just grease the grooves with a special sealant.

Concrete material, unlike polymer, has very large pores. In this regard, in the winter season, cracks may form. The tightness of the first is also provided by a rather thick bottom. Its height is about 30 cm.

And thanks to the technology of “sintering” of particles, the wells are able to withstand more than five hundred cycles of freezing - thawing without changes in the structure at temperatures from -50 ° C to + 150 ° C. They are able to absorb moisture by only 0.03%, this indicates a high level of moisture resistance.

Vandalism and resistance to aggressive substances is another significant advantage of polymer wells. Aggressive environment is absolutely not scary.As it is known, groundwater contains a lot of chemicals, which all fall on the surface of wells.

Unlike reinforced concrete, polymers do not react with aggressive substances, so you should not worry about its destruction by salts, acids, alkali and decomposition of biomass.

If we look at the whole structure with regard to the price, then it is slightly lower than, for example, in concrete wells, and this is one hundred percent plus. It would be more accurate to say that the use and maintenance of the polymer will be much cheaper. Because there is no rent of special equipment, payment for services of loaders and so on.

Practicality and durability, perhaps, the main advantage. The service life of wells over 50 years with proper operation. Manufacturers are completely safe for the reputation of giving a 100% century guarantee. But even with such prolonged use, they remain environmentally friendly.

The simplicity of connecting the well to the pipeline is also an important advantage. It is enough to make openings and holes for pipes with ordinary household tools, and the edges do not need to be treated with anything, because corrosion does not affect plastic.

The drawbacks of polymer wells are also present, but they are much smaller than merits. One of them is the inability of the material to withstand heavy loads. But this can happen only if the cap and thickness of the rings are chosen incorrectly. Therefore, you should pay attention to the choice and pay special attention to the strength and quality of parts, if the well is located near the garage or on the access road.

Depending on their ability to withstand various loads, they are divided into three categories - designed for loads up to three tons, up to seven and up to fifteen tons.

The disadvantages include the fact that the choice of such wells is quite small, but this does not reduce their popularity.

You will learn more about the benefits of polymer wells by watching the following video.

Kinds

Before we talk about the types of wells, we consider in more detail their structure. As a rule, they are made up of such parts:

- bottom (base);

- a set of annular walls;

- transition cone;

- cap.

All polymer wells primarily distinguish sizes. This affects the disposal of sewage for the day. In addition, they differ depending on the purpose:

- prefab viewing - for the storm and economic sewerage;

- sedimentary type - used to purify water from precipitation;

- storm showers - used for collecting stormwater runoff;

- collector - to connect drainage and sewer systems;

- drainage - are used in the drainage system as pivoting or connecting elements.

Polymeric wells may differ in their texture, in this case the following categories can be distinguished:

- single wall smooth;

- double-skinned smooth;

- single wall corrugated;

- double wall corrugated;

- combined.

In addition, there is another division - on the material from which the design is made.

- From polypropylene. Perhaps the most popular due to the large choice of diameters and the presence of two-and single-layer pipes.

- Of polyethylene. They are characterized by high impermeability and corrosion resistance. As a rule, are used for stormwater and household sewer systems.

- Polymer sandy. This material has appeared relatively recently, but has already managed to gain some popularity due to a number of advantages.

In appearance, there are two more types:

- prefabricated, which consist of rings;

- welded - solid structures.

There is another type of well, which is worth noting - cable polymer. Cable sewage consists of pipes and wells, it is used for laying power and low-current wires underground. Replacing and repairing cables can be done without special effort and opening the ground if the pipeline is built correctly.

Each of the above types has its own characteristics, and before choosing a well, you should pay attention to its purpose.

Polymers have another function in the installation of wells. In the process of drilling it becomes necessary to strengthen the walls of wells, especially in cases with loose soils. In these cases, polymer blends of several components are used, they are diluted with water in the right proportion and poured into the borehole. Such solutions not only prevent shedding of the walls, contribute to stabilization, but also reduce the absorption and wear of the drilling tool.

Tips

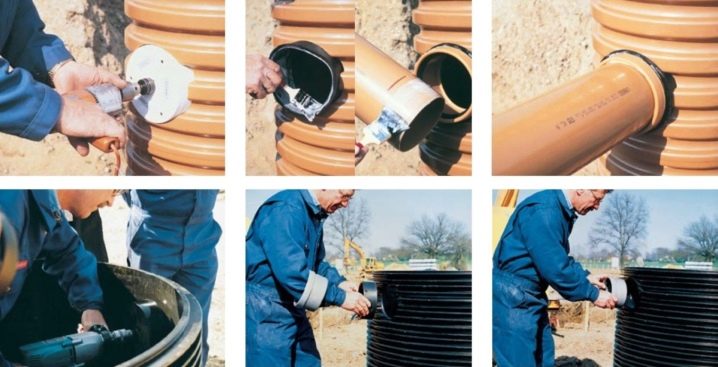

For self-installation of polymer wells on the site you need to follow a simple instruction, then you do not have to make special efforts:

- Dig a pit that fits the size of the selected well;

- its bottom must be leveled with a sand pad;

- the installation of the bottom of the structure follows;

- the installation of polymer-sanding rings, including the treatment of joints with a sealant or bitumen mastic — the first ring is laid down with a comb, and an adapter similar to a cone is put on the latter;

- after this is the installation of the hatch or cover.

For better sealing of seams, mastic will be better suited, because sealant will really take a lot, and the first option will be much cheaper, not inferior in quality. It is also recommended to check the correctness after installing the rings using a level.

To install the well, you will need a metal cable to secure the structure. During seasonal ground movements, additional attachment of the well to the foundation with cables will prevent the tank from ascending.

There are several additional details, such as stairs (they are used for quick access to the well), lids (they help prevent debris from getting inside), garbage collection (large debris is collected in the well's inner surface).

It should be noted that these designs are not used for the device of the water supply well. This is due to the fact that direct contact of polymers with drinking water is unacceptable, since it has toxic properties. Despite this, the scope of use is very wide: sewage and drainage systems, the arrangement of the caisson well and more.

Technological openings for communications can be made both before the start of the installation of the well, and in fact. The easiest way to do this is with a regular crown.

It should be noted that reviews of polymer wells are excellent. Users note for themselves high reliability, durability, ease of use and quality. When comparing with reinforced concrete, cast iron or other analogs, very many prefer polymer. The ability to choose the color of the hatch also attracts people, because it is very convenient - to make it more invisible in the grass, on the ground or on paving slabs.

In conclusion, I would like to note that the wells of the polymer-sand composite have a number of advantages over their counterparts from both reinforced concrete and other materials. Because of this, they have been spread not only among the owners of private houses, but also in various areas of construction.The design will be a great solution and alternative to the usual and expensive concrete product.