Sewer wells: device and subtleties of operation

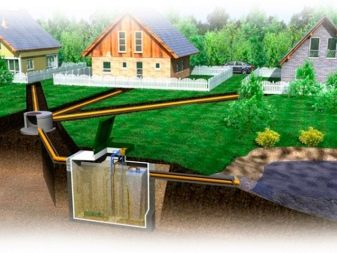

All owners of private houses are thinking about the arrangement of communication and other life support systems. Sewer wells must be present in every house, therefore it is necessary to study the device and the subtleties of operation of such facilities.

Special features

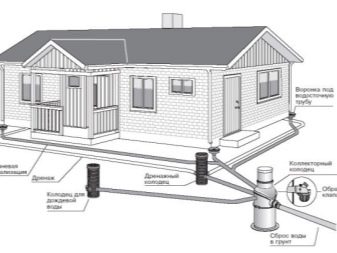

In any drainage system must be present sewer or chamber. Such equipment should be located at the entrance to the septic tank, which is located on a country site. Also, sewage facilities have a different name - wet or drainage well.

Sewerage of an autonomous type is a complex typical project of an engineering system.which installation will require sanitary and construction knowledge.The key component of each autonomous sewer is a special well.

The system should have several wells:

- lookout;

- turning;

- well under the waste of economic nature;

- well for rainwater.

The owner of suburban ownership should understand the features and differences of each type of structures.

Features of the creation of sewer wells are described in the sanitary and technical norms of building regulations. The documents describe the location of the wells, the implementation of markings and the need for preliminary preparation.

Features of arrangement according to SNiP are as follows:

- before work it is necessary to decide where the well will be;

- marking will be required on the ground;

- trees with shrubs that interfere with construction work must be uprooted;

- to the construction site you need to ensure easy passage of equipment;

- will require the preparation of a detailed scheme that is consistent with the water channel and neighbors.

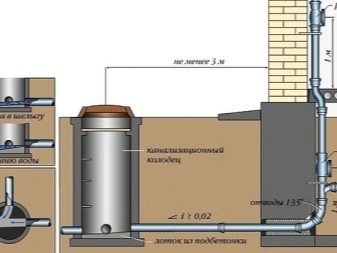

The following technical requirements are imposed on sewage wells:

- inspection structures should be located in 30-40 m increments, if the hatch diameter is 15 cm, or 50 m - with a diameter of 20 cm;

- on each pipeline bend, as well as in the branch points of the nozzle, rotary type wells should be located;

- in places where the diameter of the pipes varies or there is a sharp slope, the installation of a differential well will be required;

- there must be a minimum distance of 3 m between the storage well and the living space;

- the diameter of a modern sewer well can be 40–70 cm; auxiliary pipes can be used for the outlet.

Device and purpose

Cumulative wells are needed only for sewage autonomous type. Differential structures are used during the connection of the domestic sewage system with the central highway. Swivel and viewing structures can be installed in a stand-alone system or pipeline, which is connected to public highways.

Filtration wells can be used for drainage with clean water, in which there are no harmful substances (for the stormwater system, drains from showers or baths).

It is not allowed to filter water from washing machines and dishwashers, as the fluid contains aggressive components.

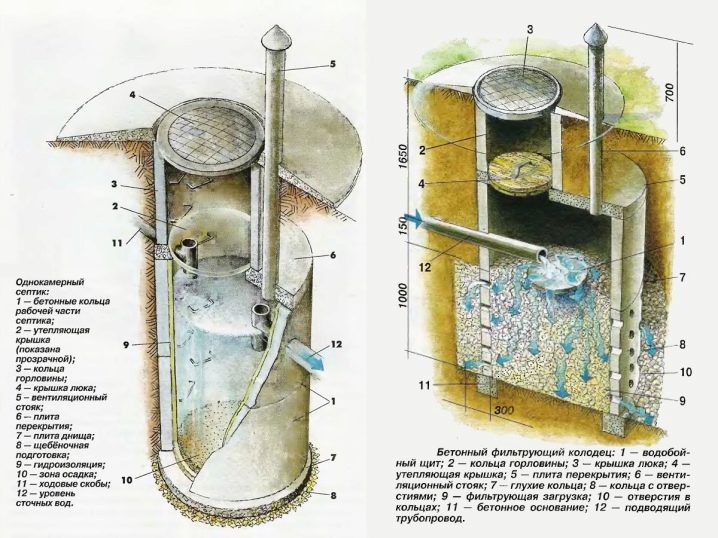

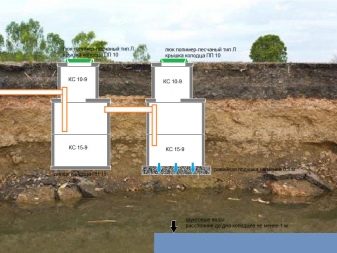

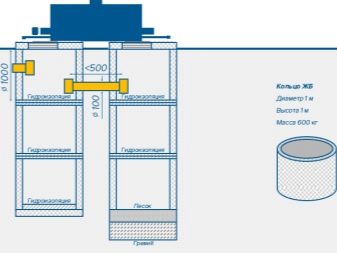

The height of household wells should not be more than 2.5 m. The diameter of the ring can be one meter. Since the soil can have a different composition, the dimensions of the well cannot be accurately determined. If the volume of one meter is not enough, then the second construction should be installed next to it with an overflow pipe.

Sewer wells may have any shape. There are round, rectangular, square types of structures. The device trays may consist of concrete rings, bricks or finished plastic containers.

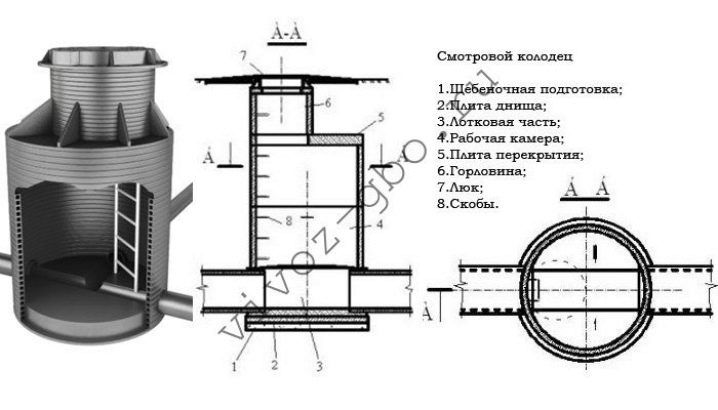

The structure of the sewer well is any form in which the following components are present:

- tray;

- base;

- working chamber;

- neck;

- Luke.

At the base of the technical design there is a tray, which is made from M200 concrete using formwork. The use of bricks, rubble stones or reinforced concrete blocks is allowed.

In the complete set of the inspection shaft there are usually some work items.

- Frame with reinforcement, which may have a square cross-section or round shape. Inside the staircase should be located.

- Slab, in which there is a hole for the hatch.

- Work hatch. It may have a round or square shape.On the outside there should be a symbol that indicates the type of well.

- Reinforced concrete is used as the basic material for the reinforcing framework. Installation of parts is carried out using a concrete ring. The bottom is a round plate.

- The bottom of the well can be poured with a solution of concrete, which enters the base of the formwork.

- On top of the design should be a cover.

Hatches can be made from several materials:

- cast iron;

- become;

- polymer

Steel hatch is the most durable option. If an inspection-type well is located on a road with heavy traffic, metal or cast-iron parts are recommended.

Kinds

There are several types of wells, which differ in their purpose and functions.

Lookout

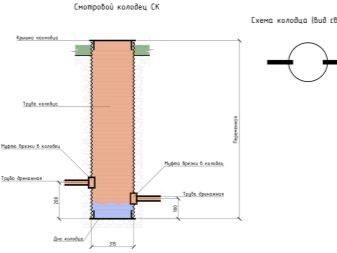

The second name of such a well is audit, control. It is created to access communication lines that are underground. Pipes with collectors of the drainage system are replaced by conventional trays. This type of construction is optimal for places where there is a change of direction, slope or diameter, as well as at the junction on the elongated and straight sections. Well allows you to check the need for cleaning the sewer.

Turning

If there is an angle or turn on the highway that exceeds 45 degrees, you will need the equipment of a rotary well. It is also required at the junctions and branching of the grid. At the same time, such a structure can be used as an observation structure.

Delta

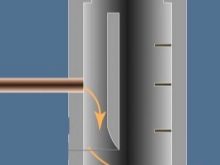

Used when joining pipelines, the depth of which may vary. With the help of overflow constructions it is possible to connect sewer pipes above the tray.

The well is intended for the following purposes:

- integration of sewer release with deep laying collectors;

- to bypass places in which underground structures intersect;

- to avoid high flow rates of wastewater, which are caused by a high slope on the site.

Distributive

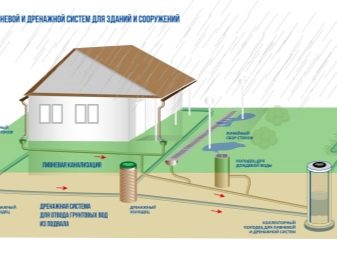

Distributive wells are used in stormwater treatment systems to control the flow of storm and thawed nature. In addition to this facility, the system consists of a sand separator, a sorption filter, an oil separator, and a well for collecting samples.

The distribution facility is a container in the form of a cylinder with fiberglass reinforced,on which there is an entrance mouth. The neck must be tightly closed with a lid.

In the case there are several holes:

- for water intake;

- openings for discharge of fluid.

All openings are located at different levels.

The construction works on the principle of simple throughput of surface water with subsequent purification and disposal with a functional in normal mode. The well is entrusted with the task, which lies in the ability to carry out activities in the extreme mode.

The device is able to function smoothly with the massive flow of excess water from the stormwater, directing the liquid in the outlet pipe. According to it, the water goes into the reserve sumps or ponds for drainage.

The design is simple, so the well is always located in the public domain for routine maintenance.

Overflow

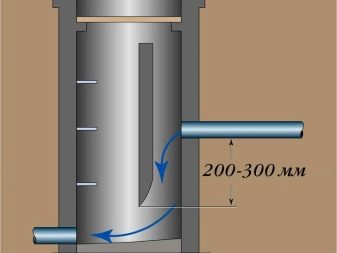

Overflow wells are also called overflow septic tanks. They are several accumulators that are connected using overflow type pipes at the top level. The construction is created to collect sewage.Impurities of insoluble character accumulate at the bottom of the first storage ring. The purified liquid flows through the inclined pipes to the next tank.

The system separates the solid and liquid phases of sewage.

Overflow wells differ in that they do not need auxiliary equipment and electricity.

Accumulative

Cumulative constructions are a modern and environmentally friendly version of the cesspool.

The facility has a significant list of advantages:

- the volume of the tank can reach 2-50 thousand liters, so you can pick up the product for any purpose;

- such wells do not contribute to the contamination of the site;

- there is no unpleasant odor near the sewage system.

Often, users prefer underground wells, which enhance the aesthetic quality of the territory.

Manufacturing materials

In the production of such materials are used.

Polymer

Polymer wells - the most common variations of such devices. Some users use unconventional methods for their production, which consist in the use of automotive rubber.This method is considered the simplest and low-cost. However, this solution does not differ tightness and long life.

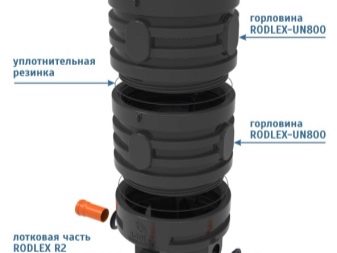

Plastic

Plastic is the simplest and most durable raw material for arranging wells. On sale there are ready-made models of polymers, you can also create such a structure with your own hands. This will require the use of corrugated pipes and plastic plates. For the construction requires a small cost along with certain skills.

Advantages of plastic:

- small weight;

- high level of reliability and durability;

- replaceability of the lower tray;

- all elements are sealed;

- You can order a container of any size.

Disadvantages:

- high price;

- specified depth of placement;

- plastic is often a non-separable item.

Models of collapsible type are endowed with versatility, as the depth may increase or decrease. Most often plastic wells are used in the role of rotating or viewing structures. However, due to tightness, such constructions can be used instead of a catchment basin. Pumping fluid is carried out using a pumping station.

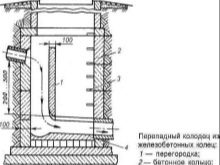

Reinforced concrete

Reinforced concrete is a classic material for the arrangement of sewage. The construction is made of concrete rings with further processing of all joints with sealant. Similar cesspools are distinguished by their great functionality.

The advantages include the following criteria:

- universal characteristics;

- long service life that exceeds 50 years;

- quick installation;

- high strength;

- material reliability;

- affordable price category.

Disadvantages:

- large mass;

- for installation will require the use of a winch and other special equipment.

Such tanks are often used in the role of viewing structures with a significant depth of the pipeline. Due to high-quality sealing concrete products can play the role of water tanks.

Arrangement

Before construction work, it will be necessary to make calculations of the required volume, as well as determine the location of the well. When making calculations you need to take into account the total number of bathrooms and people who live in the house. The volume of the well depends on the amount of water used.

If the structure is created for home use, then the height should be 2-2.5 meters. To determine the required diameter, you need to know the volume. The volume of the tank should include a reserve for a month and a half.

To calculate the required volume of a well with a circular cross section, you need to know the approximate water consumption per month.

For calculations, the formula is used:

V = L x 3.14 x R2.

V is the water consumption per month;

L is the height of the structure;

R is the radius value in a square.

To find the radius, you need to extract the square root of V / (3.14 x L).

To calculate the diameter of the cross section of the well, it will be necessary to double the radius.

Installation of a sewer well from reinforced concrete rings

Concrete rings are in great demand in utilities that service and lay underground pipelines. They are also used to create drainage and storm sewer systems, collectors. This material has no analogues in its field.

Due to its high performance, reinforced concrete can be used in any climatic conditions.Due to the large list of advantages, concrete wells are very popular.

The advantages of concrete rings for wells:

- affordable price category;

- quick installation;

- ease of waterproofing;

- high level of strength;

- long service life;

- correctness of geometric shapes;

- the rings fit snugly together, the remaining gaps are easily eliminated, so sealing is at a high level.

Concrete rings also have disadvantages:

- low splitting resistance;

- rings tend to crack;

- installation and transportation can be done only with the help of specialized equipment;

- heavy weight requires shipping and installation costs.

To build a sewer well of concrete rings with their own hands will need to perform a number of activities.

- It is necessary to develop a scheme in which all calculations and the number of materials will be displayed.

- The equipment of the pit, which is the excavation of the pit according to the required parameters, will be required.

- After creating the pit, you must perform work on the bottom of the structure.

- The implementation of the installation of the first ring, which sits on a solution of concrete.

- The pipe is inserted into the ring hole.

- All cracks that are present at the joints should be tightly covered with sealant.

- Installation of the remaining rings is done in such a way that the locks coincide in their position. All gaps at the joints are also treated with sealant.

- A concrete block with a hatch is placed on top of the resulting structure.

Construction of brick wells

In order to equip a well from bricks, it is necessary to possess certain skills and knowledge, since it is necessary to take measures to install the frame and other structures, as well as work on the external and internal design of the well. The work uses only red brick or natural stone.

Cement mortar, which is produced from river sand, is used as a connecting material. Also, to create a well will require brackets, round frame, fittings and anchors.

Below is a step-by-step guide on how to build a brick well.

- After the dimensions and volume of the structure have been calculated, the markings of the future excavation will be required.

- If the pit will have a small size, then it can be dug manually or you can ask for the services of an excavator.

- At the bottom of the formed trench, a formwork is made up, which is poured with cement mortar. The thickness of the layer should be 20 cm.

- The solution should cool for a week. Periodically, it should be moistened with water.

- Then you can begin to lay the walls on the cement solution.

- Formed walls need to be plastered with cement mortar.

- After polymerization, the process of iron plastering is carried out.

- The formation of the bottom is carried out on the basis of the purpose of the structure.

- Then you need to waterproof the dried layer of plaster. To do this, the inner surface of the well is covered with mastic or hot bitumen.

- Pipes are inserted into the prepared holes. Gaps should be sealed with silicone.

- The gaps that are present between the pit and the walls should be filled.

- In the drain wells provides ventilation, which is used to create a plastic pipe. On the pipe should wear a fungus.

- The edge of the building is covered with earth. The bottom of the well should rise 10 cm above the soil.

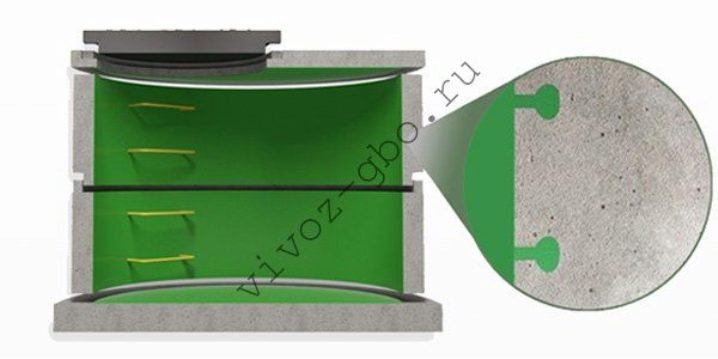

Lining

The lining of the sewer well is the equipment of the building with an auxiliary protective layer of polypropylene or polymers. This layer provides protection against the harmful effects of external stimuli. In autonomous sewers, lining is considered a mandatory event.

With the help of the lining, it is possible to protect the structure from mechanical loads, exposure to chemical reagents, temperature drops and physical pressure.

This is the most advanced method of waterproofing the well, as the polyethylene panels have all the necessary characteristics.

The implementation of the technology is carried out with the help of acid-resistant means, which are a cylinder. The element reduces the harmful effects on the substrate, excluding contact with aggressive substances on the well. Lining with sewage spraying is also in demand.

Special preparations are made of PVC, polypropylene and polyethylene. In some cases, the use of Teflon or concrete products. Concrete panels are poured with concrete solution and mounted on the formwork or directly into the working environment.

During the installation process, use mounting profiles and anchors. The installation involves extrusion welding, which cannot be done by hand, so most users use plastic rings. They are mounted in rings made of concrete and polyethylene. The thickness of the walls is about 2-8 mm.

Device installation is accompanied by the following events:

- full well drying;

- washing the walls;

- to eliminate defects, you must use a solution of cement;

- adhesive is applied;

- panels of polypropylene or polyethylene are installed on the glue base;

- sheets must be tightly in contact with each other;

- the solution is applied for the next level;

- spike connections are made using a building dryer;

- The event ends with a leak test.

Service

Sewer wells should be monitored and timely serviced. In some cases, repairs may be required. Most often there is a depressurization of the seams. To seal the seams, you can use cement mortar, which is kneaded on the basis of PVC glue.

In this work, you should use a brush for working with metal, a hammer, a spatula and a composition for sealing.

The removal of depressurization consists of several steps, described below.

- First you need to remove the remnants of the old solution. The stitches will need to be dust-free, so that the new solution is firmly fixed on the base.

- The prepared seam is lubricated with a solution. If the seams are large, you need to dig up the ground next to the well and carry out the finish outside.

- Then you will need to create a waterproofing layer. For this, bitumen mastic is used.

Also often offset rings. For the implementation of repair work will require a partial analysis of the structure. It is necessary to release the rings and reassemble, fastening with metal clips. Installation of elements is made on the solution. As a service, pumping is applied.

Regular pumping allows you to extend the life of structures, eliminates the accumulation of debris in the sewer, as well as the formation of unpleasant odors.

Cleaning is carried out in several ways:

- vacuum;

- water outlet;

- using chemical reagents;

- thermal.

The first two methods involve recourse to specialists.The latest options can be done by hand.

After the sewage system is cleaned, manual treatment is required. By following this rule, you can be sure of the maximum result.

How to make a drainage sewer, see video.