How to select and install a water pressure sensor for the water supply system?

The goal of any owner of a country house is a comfortable and comfortable dwelling. In order to achieve coziness and comfort, it is important that technical issues are resolved with the best degree of efficiency, and the maintenance and operation of all necessary engineering systems delivers as little worries and problems as possible.

Special features

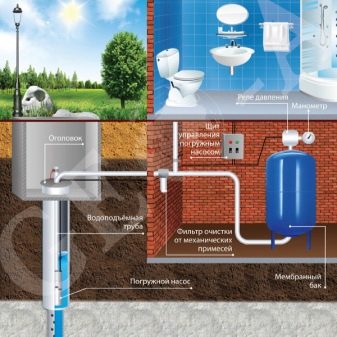

Sewage and water supply is a separate topic for discussion. To supply country houses, they usually equip special pumping stations or install submersible or deep pumps of a certain category.

An automatic pump is a device that supplies water to a house and creates the required pressure in the system, while having the ability to work in automatic mode. Automatic stations of water supply is the most popular technical solution for country houses, villas, cottages. They are also installed in the apartments. Of course, when installing and using such stations, it is necessary at least at the user's level to understand their technical characteristics, to imagine the design of these units and their principles of operation.

One of the main elements of the system are adjustment sensors. With their help, the system performs switching on and off, the correct operation of the system depends on them, therefore the choice of sensors is an important part of the work when setting up the whole complex of equipment. After all, if the range is selected incorrectly, when establishing which the sensor should work, the system will not cope with its task and will not be able to function smoothly.

If you set too wide a range, the pump will often have to respond to drops, and the pressure sensor will constantly trigger. And, on the contrary, if you set a small range level, the pump will turn on very often, which will eventually lead to its breakdown.

As a rule, all the necessary settings are configured before the sale of the unit to the buyer.But if it suddenly turns out that this is not the case (or the owner wants to improve the settings based on his own ideas about proper work), then at any time you can cope with this issue on your own. The main thing is to understand that any actions with a water sensor lead to certain consequences in the operation of the entire pumping complex. These actions can both improve and optimize the water supply, and spoil it.

Therefore, it is imperative that before starting work, examine all instructions that come with the equipment.

A water pressure sensor, sometimes referred to as a pressure switch or pressure controller, is an extremely important device. It depends on the successful operation of the entire pumping station. As mentioned above, such an important function as the automatic maintenance of the required water pressure in the system, even the minimum, depends on this small unit. Properly set pressure range will allow the pump to work optimally, avoiding overheating and keeping it in excellent condition for many years of operation.

The water pressure sensor is suitable for both wells and downhole devices.Thanks to him, there is a supply of hot and cold water, for example, for a washing machine.

Kinds

So, the water pressure sensor provides the optimum frequency of operation of the pump. But now you need to figure out what the sensors are, what these types have in common and how they differ from each other. First of all, pressure sensors are divided into two types: mechanical (electromechanical) and electronic.

Both of those and others, the main working body is a membrane that plays the role of one of the partitions of their internal reservoir into which water flows. Under the pressure created by water, the membrane is deflected and affects the other elements of the sensor, with the result that it is triggered. These elements in mechanical controllers are contacts that, when closed or opened, act on the operation of a pump — turn it on or off, respectively. That is why mechanical sensors are often also called contact sensors.

The design of the mechanical sensor consists of:

- membranes;

- contact group;

- springs of different sizes, with the help of which the working pressure range is set;

- and, finally, a pipe for connecting the unit to the pipeline.

There are two springs in the set, they have different diameters. One determines the level of water pressure at which the relay will trip and turn off the pump. The second spring is responsible for the lower level of the range, and more specifically for that range of values, at the exit of which the controller will operate and the pump will start. Mechanical sensors are designed so that it is possible to adjust the compression of both springs: if you compress the smaller one more, the pressure difference between the response levels will increase.

As for the electronic pressure switch, it works somewhat differently than the mechanical one. When the membrane vibrates, an electrical analog signal is generated. This signal is amplified, digitized and sent to the automatic control unit of the system.

Tips for choosing

Mechanical relays are simple, inexpensive and very popular. As a rule, they are made by domestic manufacturers. Models of foreign companies and more expensive and equipped with a large number of devices. They have a scale for adjustment, built-in pressure gauge and other useful devices.

Mechanical relays are very popular with owners of country houses. This can be explained by the following factors:

- these devices are quite simple in construction, which determines the reliability of their work;

- their great advantage is independence from power supply - and there is no need for a separate outlet for connection;

- the price of such a product will be significantly lower than electronic counterparts.

Most often, mechanical sensors are used in domestic systems of water supply and heating.

As for electronic pressure sensors, these units are very sensitive to any, even the slightest fluctuations and deviations from the specified parametersThe protection against dry running is also provided. There are also models on the market for which automatic start-up of the system is provided after an emergency shutdown. Such systems even notify the owner of the malfunction by sending alerts to his mobile phone. There are many other useful additional features.

Pressure sensors can be grouped according to their useful features and cost. There are three main groups:

- simple pressure controller;

- additional dry-running protection relay (supplied with a regular controller);

- complex pressure sensor (expensive device with a pressure gauge and a lot of functions).

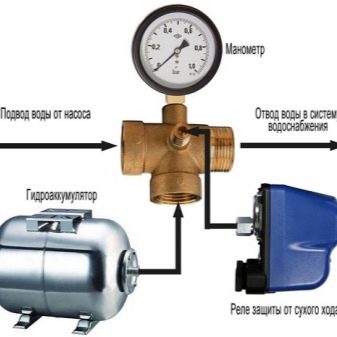

Obviously, expensive electronic relays are no more complicated than mechanical ones, but the tasks that these devices handle are much more extensive. Thus, electronic sensors have an additional controller that prevents sudden fluctuations in water pressure in the system. As a result, the uniformity of water pressure is ensured regardless of whether the pump is currently on or off. Such controllers are usually installed together with hydroaccumulators. This device monitors the continuous measurement of pressure in the system and the comparison of the readings with the set.

Thus, the choice of the device is determined primarily based on the tasks assigned to the water supply system. If the complex is needed to provide water supply, for example, at the cottage or in a small village house, then there is no need to spend money to acquire a complex and expensive system. It is better to buy simple mechanical sensors of domestic production.If we are talking about a large-scale country house and life support, for example, a large family with children, then, obviously, you should still go to more substantial expenses and purchase solid imported equipment with a large resource and productivity.

Installation

As already mentioned, high-quality water pressure controllers in the water supply system are absolutely necessary devices. Thanks to these small devices, the entire complex of equipment operates in the proper mode and retains high functionality and performance for a longer time. However, the sensors need to be replaced from time to time.

Naturally, the manufacturer and sellers will first of all advise you to contact specialized technical service centers in order to entrust the issue of system maintenance to professionals. But for a number of reasons (and one of them is the cost of such services), the owners in some cases prefer to make and install and replace sensors on their own. Indeed, if a person is not new to technical work, the operation of replacing the sensor will not be difficult for him.

Of course, before you begin, you must carefully read the detailed installation instructions that the manufacturer attaches to each device supplied.

Device

So, some more words about the device which needs to be adjusted the hands. The pressure switch is a compact unit that controls the operation of the entire pump station. It measures the water pressure in the system and, based on this information, starts or stops the pump: as soon as the pressure decreases, the pump is activated and the hydroaccumulator is filled with water. When the pressure rises to the maximum, the pump shuts off. As soon as the water level drops, the pressure decreases, the unit turns on and the cycle repeats from the beginning.

To install the sensor in the system, you need to do two main stages of work.: first connect it to the water system, and then to the power supply. After that, make adjustments and you can run the system to use uninterrupted water supply.

Wiring diagram

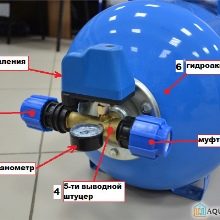

Connecting the sensor to the water supply consists of connecting the device to the water supply system.To do this, the controller has a special nut, which has a rigid mount on the sensor, so to install you have to rotate the entire device. By the way, modern models of pumps have a special regular place to install the relay. If there is no such nest, you can take an ordinary brass “herringbone” - this is an inch tee, with the help of which, in addition to the relay, you can connect a pressure gauge and a hydroaccumulator. An important place in the wiring diagram is the location of the socket for the controller.

There are situations in which the pipes or components of the pump itself make it difficult to install the sensor, in which case you will have to take care of the extension cord.

In addition, to connect to the water supply system, it is imperative to seal the threaded connection (often this is done with flax or special thread). For beginners, this process can be difficult. The next stage of installation is to connect the system to the power supply. To do this, the relay has two groups of contacts, which are usually closed, but at the maximum rate they open. The location of these contacts is always indicated in the installation instructions.It is necessary to connect the wires of the wires to the free contacts in pairs, after which the ground wire and the special screw on the controller housing should be connected to each other. After that, using a wire sensor connected to the pump.

Upon completion of these actions, you must check the functioning of the system.

You can find out how to connect the pressure switch to the pumping station by looking at the video below.