How does a water meter assembly?

During Soviet times, water could be used in unlimited quantities for a very small fee. But unfortunately, water resources are not infinite and they are getting smaller. Today, water is getting closer to oil, and therefore, its consumption is stricter. Currently, there is a federal law, according to which all consumed water is subject to calculation using special devices. To ensure the operation of such devices or meters there is a water meter unit.

What it is?

A water metering unit is considered to be a section of a pipe with various constituent elements, coming from the entrance of the central water supply system to an apartment building or a private house.With its help, the company providing water supply services, controls the amount of water used by consumers at a particular facility. For consumers, the installation of a water meter unit allows not only to control the use of water, but also to save money by analyzing the flow rate over a certain period of time.

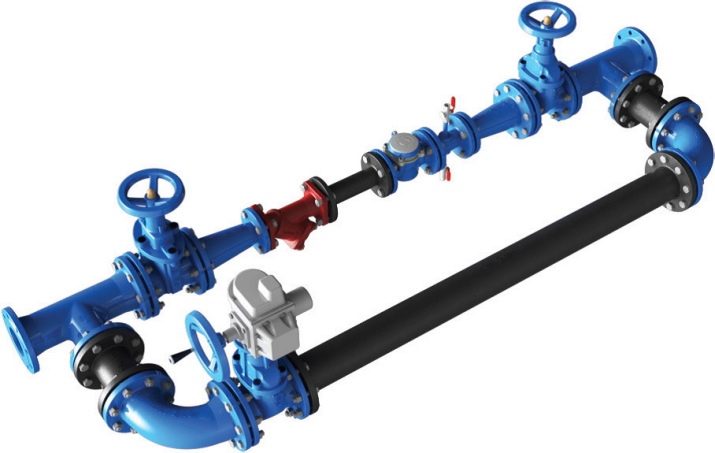

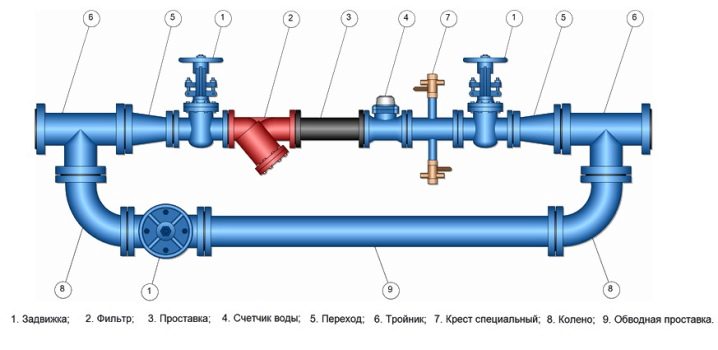

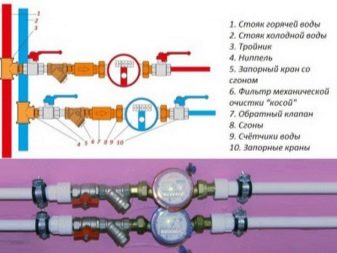

A water meter is a whole system consisting of different elements having their own purpose. The main component element of the node is the counter. Equally important parts of the system are fixing valves with a shut-off mechanism, a strainer, a crane with a fixed control and trigger mechanism, compensatory pieces of pipes in the form of pipes and other elements that perform a connecting function.

The meter shows the amount of water consumed in cubic meters. The purpose of the crane is to drain the water and monitor the pressure in the internal network; it can be used to check the accuracy of the readings of the installed meter and determine the location of water leakage in the internal system.

With the help of valves, water is blocked from entering the house from the central highway. It is used when dismantling the meter or completely draining the system. A strainer is necessary for the purification of water entering the internal system from impurities resulting from corrosive changes in pipes or emergency situations at a waterworks. Flanged nozzles are used for the installation of individual sections of the system. And the remaining connecting elements perform an auxiliary function.

Regulatory requirements

For arrangement of water meter unit It is necessary to comply with a number of requirements specifically developed and adopted in the Russian Federation.

- For installation of a water meter unit, non-residential premises with a relative humidity of 75-80% and a temperature not lower than +5? С are used. The location of the node system should be available for inspection, removal of indications, replacement or dismantling of the instrument for verification. In apartment buildings and public buildings, nodes are most often located in central heat points, basements, or specially equipped pits. For private homes can be installed in the well.

- Node installation is impossible without preliminary preparation of the system, namely crimping and flushing of pipes.Directly to the installation proceed only after filling the system pipes with water. Pipes and other components used for assembly and subsequent installation must be rigidly fixed to the surface of the floor or wall. In order for the water pressure not to decrease with the commissioning of the unit, it is recommended to use the minimum number of elbows and fittings during installation.

- The design of the site and the installation of the metering device should be carried out in accordance with the regulatory documents and accepted standards (SNiP, technical passport counter). The measuring device is always installed on a straight line and at a certain height from the floor level, as a rule, it ranges from 300-1000 mm. The length of sections on each side of the measuring instrument must comply with state standards for measuring instruments (SNiP).

- The installed device must have a manufacturer's passport with the date of issue and a state-approved certificate. After installation, the device must be necessarily protected from unauthorized interference by installing a seal.Sealing the metering device with the issuance of an official permit for operation is made by the company providing water supply services.

- To estimate the volume of cold water, install a device with the marking of cold-water, and for calculating hot water - a meter with marking of hot water. The cold water meter is subject to verification once every 6 years, and the operation of the hot water meter is checked once every 4 years.

- The verification of measuring instruments is carried out either by organizations with appropriate accreditation, or by a company that provides maintenance of this node, with the issuance of an appropriate conclusion. To test the measuring device, you can use special equipment that eliminates the possibility of dismantling. As a rule, ultrasonic, electromagnetic and mobile test devices are used.

Kinds

The classification of gauges depends on the number of lines and the design features of the measuring device installed on the line.

- Depending on the number of lines in the structure, and gauges divided into simple, consisting of one line, and complex, with a bypass line. Constructions with a bypass line are to be installed at sites with a single water inlet. This system is also provided if the installed meter is not designed to pass water in sufficient quantity for fire extinguishing systems. In order to provide water for the fire extinguishing system, an additional valve is mounted on the bypass line, which is automatically set in motion, due to the electric drive.

- Depending on the meters used in the construction, nodes are divided into tachometric, electromagnetic, vortex and ultrasonic. A tachometer counter is one of the most common and standard metering devices installed directly in pipes whose diameter does not exceed 400 mm. Water flow is measured by the rotation of the working fluid, driven by the flow. The higher the rotation speed, the greater the volume flow. Division tachometric metering devices depends on the internal structure.

Today there are: wing, turbine and combined counters.

- For buildings with a small amount of water consumed, where the diameter of the pipes is in the range of 15-40 mm, set wing sectional water meters. These meters are mounted exclusively on horizontal sections, the connecting elements of which are interconnected by means of a thread. Such an installation is related to their internal structure. For a more accurate measurement of the volume of water consumed, the axis of the instrument should be in a perpendicular position with respect to the fluid flow. Counters for hot water can withstand temperatures up to +150 degrees, and used in the nodes of cold water supply withstand temperatures not more than +40 degrees.

- Turbine counters in contrast to the wing can be mounted not only in horizontal but also in vertical position. In this case, the flow of water runs parallel to the axis of rotation. The vertical arrangement of the device is possible if the incoming water flows in an ascending type. Water meter units with a turbine-type counter are installed in buildings with high water consumption, where the pipes have a diameter of 50-250 mm.

- In the combined devices accounting, there are elements of the wing and turbine counter. Such structures are indispensable if the building is fixed uneven consumption of water resources, as well as sharp fluctuations in consumption.

The method of supplying water to the device allows dividing tachometer counters into single-jet and multi-jet types. The flow of water passing through the single-jet counter mechanism causes the spring to move around the impeller to rotate. To set the impeller in motion, the flow of water in multi-jet counters is first divided into small streams and only then falls on the blades. Multiple-jet types belong to the most accurate metering devices of this class.

To measure large volumes of water consumed in large enterprises install electromagnetic metering devices. Their work is based on the analysis of changes in the magnetic field created inside the meter by the flow of water. Electromagnetic models of water meters are high-precision measuring instruments that can withstand any pressure inside the system, producing accurate flow rates for a certain period of time. By connecting to a laptop computer, you can schedule a flow for different periods in the dynamics.

The work of vortex counters is based on the analysis of the speed and intensity of the vortices measured by a piezoelectric element located inside the device.In ultrasonic devices, water flow is measured by analyzing the displacements of the ultrasonic wave created by the flow of water. The interval of passage of the wave is fixed with a piezo receiver. Ultrasonic devices are used in the nodes where it is impossible to install electromagnetic meters due to impurities in the water, in particular, to calculate the volume of wastewater. For trapping impurities most often used mesh filter DN 100, the use of filters with a smaller cross-section can lead to a pressure drop.

Device

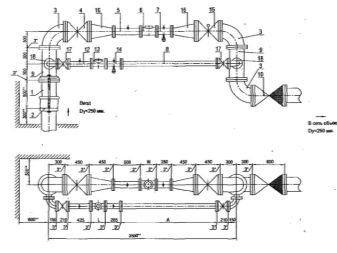

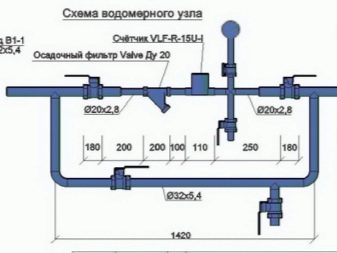

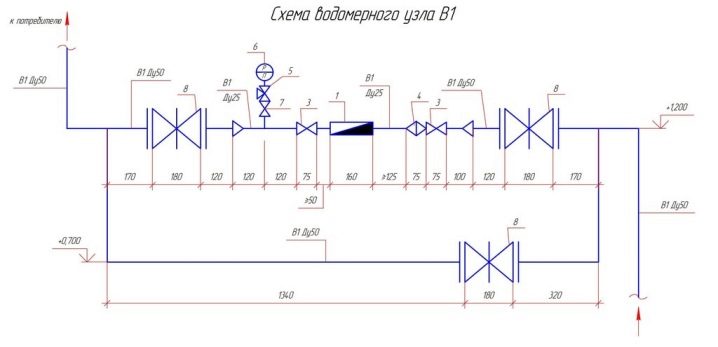

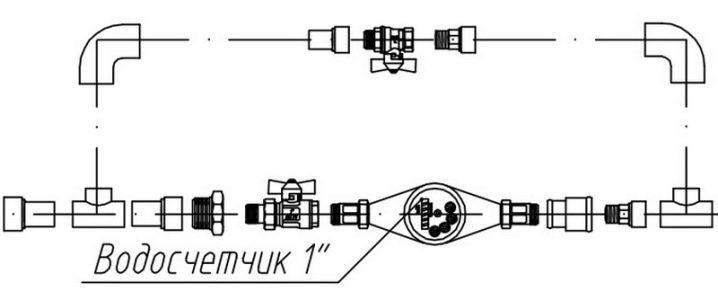

A water meter project is a diagram on which the location of all the constituent elements and connections are detailed. There are different schemes for the location of water metering units. But the sequence for any scheme should remain unchanged: first comes the locking device (gate valve, valve), then the pipe section with filter, and only then the metering device. When installing the meter must comply with certain requirements. The length of the direct connecting elements emanating from the device in both directions must correspond to the value specified in the document for the specific model of the meter.Similar requirements are imposed on the diameters of the sections and the conditional passage of the device; they must correspond to each other.

The length of the direct connecting elements is formed at the expense of fittings with cap nuts, which are included with the meter. If they provide the length specified in the passport of the device, and the diameter of the nominal meter passage corresponds to the diameter of straight sections, then there is no need to install a transition element. If there is a discrepancy in length, and the diameters are the same, then an elongated fitting with cap nuts is mounted. If the diameter does not match, a transition element is installed.

To increase the length in straight sections with non-compliance with the declared value, use couplings and sleeves (straight or angled), and if the diameters do not match, the transition element is used. Combined installation of additional elements is also allowed. Sgon can be installed between the filtering device and the meter or between the locking and filtering device.

The scheme also provides for the presence of tanks, circulation systems, and in the event of a difficult discharge of water, a second locking device is also allowed.installed after the metering device.In addition, a drain valve or a stopper is included in the assembly diagram in case it is planned to drain water directly from the assembly and monitor the water pressure at the outlet of the device. To control the pressure in the circuit can be included a regulator located between the valve and the meter. It includes, if the ball valves, valves and turning devices cannot provide smooth flow control, to protect the meter from water hammer, and also if it is required to periodically reduce the pressure to the optimum value.

On projects draw not only the scheme of the water meter with all the components. If there are several nodes indicate the location of each with the designation of the diameters of underwater highways.

Tips

To carry out the selection of the meter for the water meter unit should be based on several factors.

- It is necessary to take into account the pressure and temperature of the water, the limit of sensitivity and the allowable pressure loss. The most important characteristic is the limit of sensitivity, it depends on it, for what diameter of pipes the metering device is purchased. It makes no sense to buy a meter with a large diameter for small amounts of water, as it simply does not fix them, its threshold of sensitivity is higher.

- Ordinary tachometer counters are suitable for apartments and private houses with small diameter pipes. But it is worth remembering that all mechanical models are sensitive to electromagnetic fields, and their accuracy is directly dependent on the quality of incoming water. Electromagnetic is much more accurate than mechanical models, but they are several times more expensive, in addition, for their work requires a power source.

- Counters for hot water can be installed in units with cold water supply, since their temperature range is wider than that of models designed to measure the volume of cold water, but not vice versa.

- It is better to buy a metering device in specialized stores. When buying, you should pay attention to the release date specified in the technical passport. The date of verification is counted from the date of issue, and not from the date of installation. The more time this device has lain on the counter, the faster the calibration date will come.

- It is better to entrust the installation of the meter in the apartment to specialists with the appropriate license, and the company servicing the object should carry out the sealing and registration of the device.

For information on how to properly install a water meter, see the following video.