Membrane broad tanks of Reflex: device and features of operation

The membrane membrane Reflex brands are modern high-tech containers. These devices protect engineering systems with pumps and valves against sudden pressure surges. Devices successfully compensate for the thermal expansion of fluids used in the systems.

Specifications

Modern tanks used as a spreader have similar qualities.

Reflex tanks have the following general characteristics:

- Membrane tank is made only from a quality base.

- The product is necessarily coated with polymer compounds that perform the function of protection against corrosion.

- Available in tanks of various colors.

- A membrane is a container shell that cannot be replaced.

- A hydroaccumulator with a membrane for heating provides for a compartment filled with gas, which is replenished in production to a pressure of 1.5 bar.

- The instruction manual tanks indicated that they can be used at maximum temperatures up to 120 degrees.

The only distinguishing characteristic of the Reflex tanks of this line is the nominal volume and shape. The options are from 3 to 10 bar. Fastening tanks can be carried out both on the wall and mounted on the tank support.

Tanks are produced in various series, each of which has its own indicative qualities.

For example, Reflex DE 100 tanks have:

- volumes - up to 100 liters;

- weight - 27 kg;

- dimensions: 48 cm diameter, 83 cm - height.

- throughput pressure - 10 bar;

- the highest working temperature - 70 degrees;

- the lowest working temperature - 10 degrees;

- nitrogen pressure in the gas chamber - 4 bar.

Additional features include:

- membrane breakout device;

- threaded connection;

- epoxy outdoor coating.

Installation requirements for tanks vary and are usually associated with the quality characteristics of the system. Capacities are different in purpose. This is usually indicated in the accompanying documents.

Purpose

Hydroaccumulators Reflex can be used as:

- protection of the engineering network from impacts, which are caused by hydraulic influence;

- water tank, which is necessary in the temporary absence of water supply;

- expansion tank suitable for hot water systems;

- reliable detail that improves the work of plumbing or heating equipment.

Most often, containers are used in private homes as expansion tanks for water heating. Tanks are also used in industrial plants.

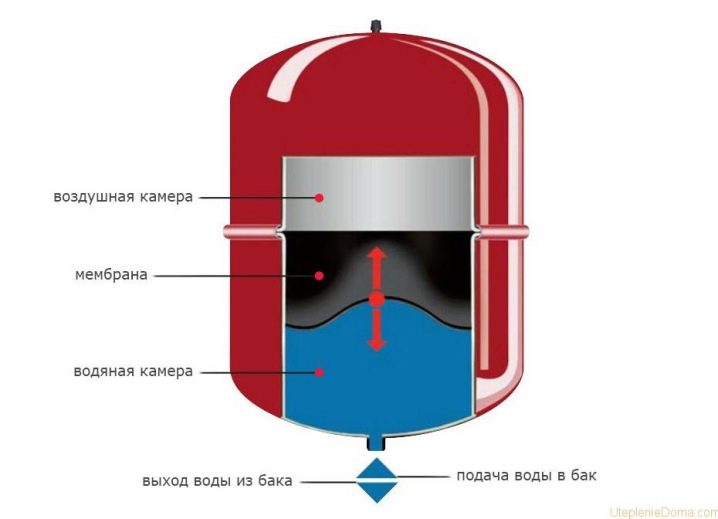

For the manufacture of containers used high-quality materials with polymer coatings. Standard containers are divided into two parts. In one of them, a low-inert gas — nitrogen — is pumped into the production. In the second chamber, you can pump water.

The gas compartment from the chamber with the liquid separates the rubber membrane. Pressure is regulated by means of a pneumatic valve. It contributes to the bleeding of excess volume that occurs in the water chamber when the liquid is heated. In the capacity of the same water can be pumped.

When a certain threshold is reached, a relay is triggered, which turns off the pump.When water is taken from the tank, the pressure drops, automatically the device drives the pump. Hydraulic tanks are characterized by different efficiencies, which are often associated with their volumes.

Advantages and disadvantages

Reflex is a German manufacturer whose products have a lot of positive feedback. They testify to the reliability of the equipment. Users note the strength of the base, the wear resistance of the membrane.

The hydraulic tank has other positive qualities:

- It does not need to be connected to electricity.

- Installation is simple.

- Application is possible, regardless of the type of coolant.

- The range is presented in a rich variety.

- It is possible to connect to the central water supply system.

- Suppose the choice among the options of solar-collector type, which are connected to heating systems.

- In the pipelines with coolant excluded oxygen.

- No need to control the amount of water in the system.

- No need for thermal insulation.

Despite numerous advantages, users point out some significant disadvantages of hydraulic tanks. For example, sometimes there are difficulties with maintenance.In heating circulation systems, there is a need for constant pressure control, and it is necessary to systematically perform pumping. The upper part needs additional equipment with a valve that will help remove excess air. This air may still be in the system.

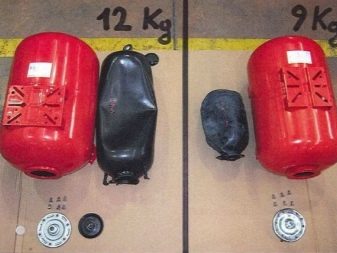

Often, users are considered to be negative and non-replaceable inner membrane. But the manufacturer claims that the shell can serve a long time and very rarely loses its functional features ahead of time.

Also, many of the disadvantages include the high cost of products. However, it is worth noting that the cost of models is associated with the presence of additional components. The most expensive models belong to the latest generation of the S series.

It will be cheaper for users of 8-140 liters capacity, which are marked with NG. By the way, the G series includes expansion tanks with a membrane that can be changed. Models of a series N - the cheapest at cost.

Product Overview

DD series membrane tanks - This design, called hydroaccumulators. The use of structures is possible in the systems of individual water supply together with heating elements.The volume of tanks varies in the range from 8 to 33 liters. Models come in white or green colors.

This model range combines DT 5, DE, HW subseries volume up to 500 liters. These membrane structures are designed for systems with high water consumption. They are used in business, personal or fire systems.

Pneumatic Tanks DE for water carrier usually come in blue. The presence of flow-through or drain additional devices is not provided. As a rule, models are used in household or individual water supply systems, as well as fire-fighting systems. The pressure calculated on the production - up to 25 bar. Models with a volume of 50 liters are supplied with a replaceable membrane.

Bucky hw There are also blue, usually horizontal, volumes from 25 to 100 liters. Used for individual water supply systems as a reservoir for water supply. The pressure in the tank is 10 bar. The model provides for the installation of auxiliary pumping equipment. As an option, special legs and hooks are available.

Smaller volumes differ C series tanks - up to 80 liters.Models are made of quality material called butyl rubber. Installation is possible on the wall through a special loop. The shape of the design is improved, flat, cylindrical.

Tanks F Series differ in even smaller volumes - from 8 to 24 liters. Tanks, as a rule, of round or cylindrical shape are supplemented with hooks for installation. Some variations have additional options, but the price depends on their availability.

S Series Tank Options it is possible to apply both to water supply, and to heating. Capacities are from 2 to 600 liters. The equipment includes a threaded connection and a membrane shell that cannot be replaced. Capacities can be used for systems with antifreeze with a concentration of not more than 50%.

Capacities of a series G - these are rather various models containing from 100 to 1000 liters. Perhaps a special execution of containers up to 5000 liters. Pneumatic manometers, threaded or flanged connections are available as equipment. Capacities provide a replaceable membrane. Usually they are available in red.

N Series Options Available in volumes from 200 to 1000 liters. Tanks are equipped with a fixed membrane, which is considered the most resistant to wear. Practice shows that the service life of such tanks is the best.

NG Series Options 35 have a capacity of 8 to 140 liters with a nitrogen chamber of about 6 bar and equipment in the form of a threaded connection. Capacities of this series can have various additions on which the total cost of products will depend.

Recommendations for use

Calculations of the volume of containers associated with several parameters:

- total system volume;

- the composition of the coolant;

- membrane capacity efficiency.

The correct calculation formula will look like this: V = (VL * E) | D, where:

- VL is the total capacity of all components of the system (pipeline, radiators, boiler);

- E is the coefficient of expansion of the fluid, which is associated with its temperature and quality;

- D is the efficiency of membrane capacity.

Calculate correctly the total volume of the engineering system is quite difficult. But all values are usually contained in the instructions for the installed devices.

You can also consider the following indicators:

- If the boiler is solid fuel, then its volume can be from 10 to 25 liters.

- If the boiler is parapet or gas powered, then its possible capacity is from 3 to 7 liters.

The volume of fluid in pipelines is related to their diameter and length. Internal capacity can also be found according to the instructions.The internal capacity of the running meter must be multiplied by the total length. The working capacity of the radiators is available in the accompanying documentation. You can also take into account that on average this indicator can be from 7 to 17 l / kW.

The coefficient of expansion, which in our formula is designated by the letter E, is associated with the temperature of the liquid, for example, for ordinary water it will be equal to 95 degrees, while the figure is equal to 4%. If the content of ethylene glycol in the liquid is about 10%, then E = (10-4) * 1.1 = 4.4%.

The effectiveness of the described containers is a relative value. To determine the value you need to know the working pressure in the tank at which the safety valve operates. For example, in a heating system in a two-story five-meter house, the pressure should be about 0.5 bar.

You can consider the following example for the calculation in the case of a system with a capacity of 50 kW, a height of 2 meters. As the thermal carrier the usual water acts.

Values will look like this:

- VL- 50 * 15 = 750;

- E = 0.048;

- D = (2.5-0.5) | (2.5 + 1) = 0.57.

V = 750 * 0.048 | 0.57 = 63.17. This means that a model with a volume of at least 60 liters will be required for the settlement system. Working pressure will provide the model series DE.Suitable options are among the devices of the C series.

Rubber pears of both series meet hygienic and sanitary requirements. They can be used for drinking water, while no harmful bacteria will affect the containers.

Storage tanks with relays can be configured to fluctuate the atmosphere from 2 to 4. In this case, the tank will be enough to meet the needs of the owner of a private house.

About Reflex expansion tanks and their installation, see the following video.