Needle valve: characteristic and application

The needle valve is an important element of the valve for adjusting the water temperature and the main engineering communications in industrial and residential buildings. When using valves with a diameter of fifty, thirty-two and ten millimeters, regulated water flow. Most often they are placed where the pressure reaches about 9.8 MP.

The valve itself is designed in such a way that it has a rotating stem, which, through a threaded pair with a special nut, delivers movement to the locking element-spool.

Valve types

There are many types of valves, however, they can be divided into two types.

- Passable - the same direction of flow at the entrance / exit.When installing the valve on any part of the pipe, its spindle should be at the top or horizontally, the installation should not be allowed down.

- Corner - have perpendicular directions of entry and exit streams. The difference of the angular valve from the checkpoint is that it is installed in the sections of the pipeline turning at ninety degrees.

Features and parameters

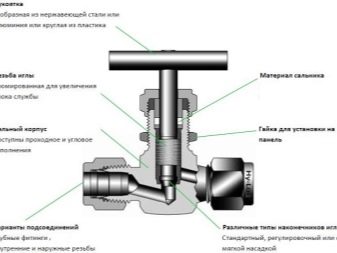

The unit consists of several parts:

- main body;

- rotary handle;

- stock;

- seal;

- nut;

- omental cap;

- casing;

- set screw.

When the handle rotates, the stem lowers, closing the pressure of the fluid. During reverse rotation, the pipeline becomes free again.

The action of the needle valve depends on the plunger, its shape and stroke. The main advantage of the product is a simple design, as a result of which it does not require professional skills and abilities for assembly and disassembly. It should be disassembled at failure of insulation elements that are easily replaced. The valve itself is made of stainless material, which significantly extends the life of the valve.

Without flaws, however, no cost. In places where there is increased viscosity (for example, the area of work with oil), the valve can not be used.As well as with large pollution or in places of especially high hydraulic pressure.

The main advantages are:

- if the valve is made of stainless material, then its service life will be extremely long;

- all flows are infinitely adjustable;

- working temperatures range from 20 to 200 degrees Celsius;

- The valve is able to withstand enormous pressure loads (about 220 bar).

The main disadvantages:

- one-sided feed;

- increased hydraulic resistance;

- large construction length.

Important: plungers with needle configurations can not completely eliminate the possibility of leakage, but this is not necessary because it is shut off. The valve section regulates only the flow of the medium relative to its own movement.

There are two options for controlling needle valves: manual and automatic. The first implies the usual turn of the control lever with your own hands, it can be put on each pipeline. The second is referring to the direct control of the fluid by the device itself. These valves are often placed in heating systems.

Areas of use

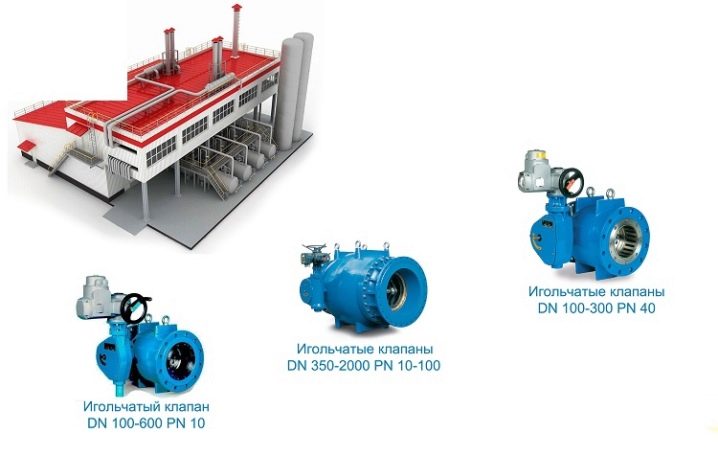

With the help of a needle valve, it is possible to regulate not only the flow of a liquid, but also gas, water, and food or corrosive vapors.As a rule, such devices are placed on auxiliary water mains.

There are valves with a handle of conical shape, which are often used to regulate gas flows (in small quantities), often they are used to inject cooling water and other liquids. A separate valve type is used for heating.

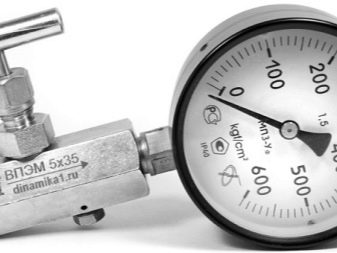

To control the pressure on specific sections of the pipeline, place a valve that has a directly shut-off mechanism for a pressure gauge that measures the pressure drop. Moreover, such a mechanism allows, if necessary, to block flows in the automaton mode.

How to choose the right device?

Before you get a valve, you will definitely need to find out in which place the pipes will install it, what is the diameter of the pipe, what is the peculiarity of the medium inside. The dimensions of the device must match the pipe. It is best if both objects are made of the same or similar materials.

It is necessary to take into account the pressure at which liquids or gases move through the pipe. If the pressure does not reach fifteen MP, then any needle valve will work.But if the pressure readings are higher, then valves of markings VI and BT-5 will do. They are able to withstand pressure up to forty-five MP.

It is worth paying attention to whether the device has a direct direction indicating which parts of the valve are in contact with the leading sections in the pipe and the discharge. If the installation was done correctly, the flow will overlap when the handle is rotated clockwise, and the opening is against it.

Before buying it is important to make sure that all parts are intact and do not have chips, cracks, the surface is not covered with scratches, since all this can significantly reduce the time of the valve. It is important that the handle rotates in both directions, and the stem at the same time worked. Rotation occurs only up and down, if there are movements in different directions or parts are loose - the valve is defective, and it is impossible to take it.

When choosing, it is also worth considering the environment in which the device will be placed:

- oil;

- chemistry;

- food industry;

- utilities;

- thermal and water supply.

Different materials need different materials, and the mechanisms themselves will vary in price levels,Rust resistance and working temperature.

If we take the category of materials, then devices made from gray cast iron are well suited to the water supply. Bronze is used in corrosive environments, and carbon steel valves are used at high pressure. For heating plants where high heat resistance is needed, chromium-molybdenum steel is used.

The valve, which is allowed to be installed almost everywhere, is made of brass. It is a durable material that does not lend itself to any mechanical stress and does not rust. The budget substitute for brass devices is silumin, which is softer and much more susceptible to various kinds of damage. Often, in order not to distinguish the materials from each other, brass and silumin are covered with a layer of chromium, but you can distinguish them by weight, since brass is much heavier.

How to connect, crimp and lubricate needle valves, see the following video.