Water pressure regulator in the water supply system: functions, installation and adjustment

Under the reconstruction or installation of a new water supply system means the installation of all water supply devices and additional structural parts. Many of these parts must meet stringent environmental requirements. Their violation contributes to the shortening of the equipment service life One of these requirements is to control the allowable pressure in the water supply system.

The water pressure regulator in the water supply system is necessary for setting and stabilizing the pressure in the water supply network. The need to install the device is indicated in the regulatory and technical documents. It is installed on the risers of houses and apartments.Pressure regulator is the most important instrument for saving water consumption.

Features and Purpose

The main purpose of the regulator is to optimize pressure and maintain it at the same level, preventing the formation of loads and hydraulic shocks in the water supply system. This is ensured by a temporary cutoff of the fluid supply when the pressure rises above the established norm.

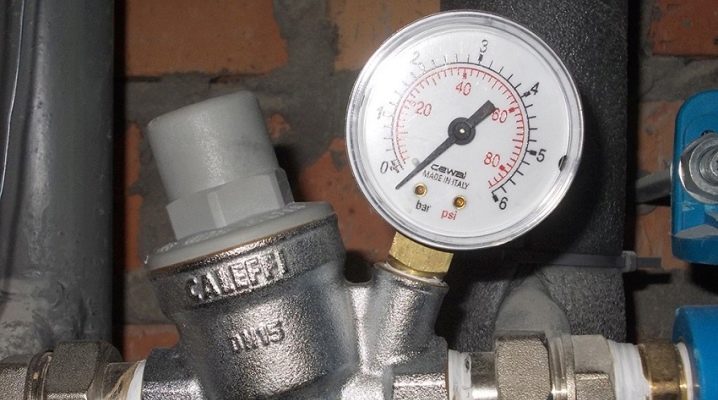

The device is a safety device with input and output threads. It can be equipped with a pressure gauge so that the pressure in the water supply can be measured, and with a screw to regulate the pressure of the liquid.

To supply cold water, the regulator must be installed:

- on municipal and technological pipelines;

- in fire extinguishing systems;

- on the main pipeline in pumping stations;

- at water points;

- in irrigation and land improvement systems.

Reasons for installing a pressure regulator:

- Pressure above 3 atmospheres often increases. This usually happens in old apartment buildings.

- Breakdown of the meter and fogging of the glass as a result of a sharp increase or decrease in pressure, as well as poor quality of the device.

The advantages of using the regulator:

- allows to increase the service life of household appliances due to optimization of pressure in the line of consumers;

- water consumption drops when the pressure drops to the norm;

- protection of a water supply system against water hammer;

- noise reduction;

- allows to reduce the risk of equipment breakage at sudden pressure surges.

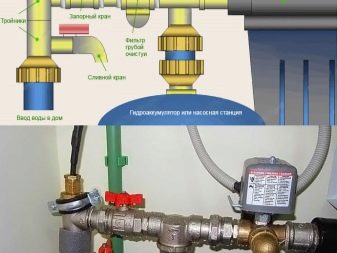

The reducer is not recommended to be installed if the private household has a complete water supply system. Here, the relay together with the hydroaccumulator acts as a regulator, that is, optimizes pressure and quenches hydraulic shocks. And there is also no need to install a gearbox if the water supply system is common in an apartment building. In this case, the water supply system includes a pumping station, hydroaccumulator, pressure regulator and other necessary devices. They are serviced by utilities.

Types and device

Today, the market is represented by a huge range of pressure regulators for use in everyday life and industry.

Depending on the technical characteristics of gearboxes are classified by:

- working mechanism: piston or valve;

- working mechanism: membrane or spring;

- throughput: industrial (more than 16 m3), commercial (3–15 m3), household (less than 3 m3);

- body material: cast iron, stainless steel, brass, nickel or chrome plating;

- fastening method: flange or threaded connection;

- type of workflow;

- the size of the body and the type of flange connections.

The lever flange regulator is designed to optimize the pressure before and after the installation site, as well as to stabilize the pressure stresses. The lever reducer reduces pressure, noise, vibration, increases the service life of household hydraulic equipment.

Design features:

- cast iron or steel case;

- the cover equipped with omental consolidation;

- stock;

- lever to support access control with supports and load;

- diaphragm actuator.

In these devices, the position of the working mechanism in relation to the saddle is different. Pressure regulation involves calculating the mass and choosing the location of the load on the lever.

The household water pressure regulator is a domestic device of the Pascal safety fittings plant.It is designed to reduce noise, vibration and pressure, increasing the service life of hydraulic devices. The installation of regulators leads to a reduction in energy consumption and the cost of utility water systems.

A direct-acting pressure regulator is a pressure stabilizer that uses the energy of a network flow.

Design features:

- housing with flanges;

- rod and bushings;

- main valve;

- diaphragm valve;

- pulse tube.

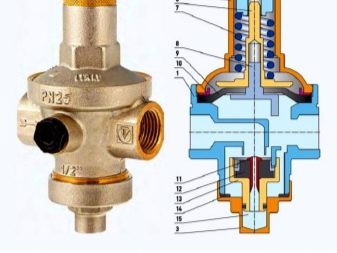

Honeywell Water Pressure Regulator provides a decrease in overpressure in the plumbing system, stabilizes network parameters, and saves water consumption. Silent operation of the gearbox is due to the constant pressure through the flow area. The principle of operation of the device is based on the opposing forces of the diaphragm and spring when exposed to too much pressure.

The manufacturer produces a combined version of the filter elements with a regulating function and a flush valve. The filter provides preliminary purification of water from solid particles, thereby improving its quality, increasing the life of the water supply system and household appliances.

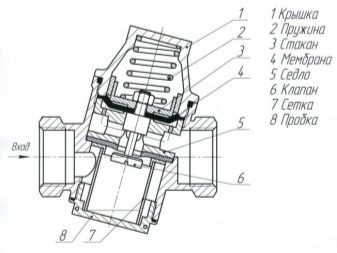

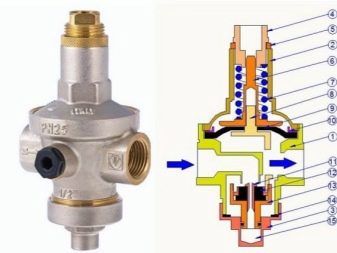

Device device:

- housing with threaded connection and pressure gauge socket;

- adjustment knob, equipped with a scale;

- adjusting spring, which acts as a working body;

- executive parts - the valve and diaphragm.

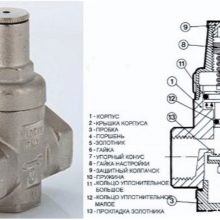

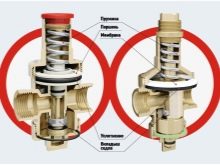

Piston, or mechanical regulator is one of the most common types of mechanisms designed to reduce pressure. Such popularity is caused by low cost relative to other types of regulators. Consists of an adjustable piston that is driven by spring force and valve pressure.

The principle of operation of a piston gearbox is based on a change in the conditional passage, as a result of which the water flow changes. If the pressure is insufficient, the valve may open for the entire conditional passage of the pipeline.

The manufacturer on the device sets the factory pressure to 3 bar. If there is a need to reduce the pressure in the pipeline, use the screwdriver to twist the adjusting head clockwise. One turn contributes to a change in resistance by ½ bar.

The body of the piston pressure regulator is made of non-ferrous metal or stainless steel and consists of the following elements:

- work item - piston;

- spring;

- adjustment screw;

- sealing rings.

In order to avoid increased noise level, it is recommended to additionally install a valve for air discharge, a sump and a pressure gauge on the line.

In order for the water temperature to remain at the same level, it is necessary both in the hot water supply system and in the cold system to establish the same pressure values on the manometer.

Piston design has several significant drawbacks. First, the fear of polluted water? Therefore, if sand and rust are present in water, the system should be equipped with fine and coarse filter elements. Secondly, the presence of moving parts that quickly wear out. As a result, the equipment fails.

The membrane regulator consists of an elastic membrane supported by a spring. In this case, the regulator is divided into two parts: the first part is in contact with the liquid, and the other is equipped with a spring and does not come into contact with the liquid medium. The membrane at the expense of the spring acts on the valve, and the diameter of the nominal passage of the pipe increases. Since the membrane has elasticity. the camera is “forced” to pass mechanical impurities that do not affect the main functions of the gearbox. The device is controlled by an adjusting screw.

The membrane mechanism does not require cleaning, its repair involves only the replacement of the diaphragm. The device is not equipped with moving parts, driven from the outside. Compared with the piston mechanism, the membrane regulator is considered more reliable in operation. But this device has a high price, a large number of moving parts and the complexity of the replacement mechanism.

Types of regulators are divided by type of control.

The electronic regulator is designed to turn on pumping equipment of small capacity when taking water from the water mains. It is installed in apartments, private houses and cottages. The electronic device provides shutdown of the pump in order to avoid idling, prevents hydraulic shocks due to the electronic controller and reports the changed values of flow and pressure.

The equipment differs in silent work. Installation is carried out to the first mark of the water intake point. Before putting into operation, it is imperative to fill the pump unit with water.

Constructive parts:

- housing;

- cap;

- polymer bushings for attaching an electrical cable;

- branch pipes for connection to the water mains;

- diaphragm;

- the electronic board;

- electronic sensor in a protective casing.

Automatic regulators are equipped with special relays that allow you to adjust the water pressure. The equipment is a small block with a membrane and a pair of springs. The level of compression and return to its original position is regulated with the help of nuts. A special relay acts as a pressure stabilizer in the water supply system, and also automates the process of controlling the pumping station.

Types of regulators at the place of installation on the pipeline:

- Gearboxes "to themselves", that is, they optimize the pressure in the water supply to the regulator. They automatically maintain the adjusted parameter of the water pressure due to a change in the conditional passage through the valve, which is in the open position until the set pressure in the network is adjusted. This type of gearbox is recommended to be installed at pumping stations and in heating systems.

- Gearboxes "after themselves" stabilize the water pressure, optimizing the pressure in the main pipeline. Are mounted behind the device in household pipelines.

Principle of operation

The pressure reducer is a valve that holds and regulates the pressure.The force of flow changes the flow area, connects the valve with the seat, and then closes or opens the passage for the flow of fluid independently. The increase in pressure contributes to the complete or partial blocking of the passage.

The principle of operation of the device is based on the optimization of the forces of two types of equipment under the pressure of water. The spring membrane acts on the network pressure of the water supply system from one side, and the spring on the membrane - from the reverse. When the pressure rises above the permissible water, the membrane presses the membrane, which, in turn, causes the valve to move.

In order for the device to work properly, it is recommended to install the regulator strictly according to a specific scheme, which is indicated in the technical documents of the device.

Criterias of choice

Currently, there are many names of water pressure regulators for apartments and private houses, but their quality does not always correspond to the declared. Therefore, you need to know some criteria for selecting devices to protect hydraulic equipment from high pressure and hydraulic shocks.

The instrument case is made of expensive materials such as stainless steel, brass and bronze.It is recommended to take several regulators and compare their weight. It is necessary to choose the device that is heavier and without burrs with burrs. It is necessary to pay special attention to the connecting seams. Low-quality regulators are often sprayed.

It is best to contact a specialized company to purchase a quality device.

When selecting the optimal variant of the regulator, it is necessary to take into account such parameters as throughput - water consumption per hour (in m3) and the unit of account, which makes it possible to reduce the pressure in the system. The local resistance generated at the site does not significantly affect the operation of the entire water supply system. Adjustable regulator depends on the sensitivity of the membrane, and its quality depends on the degree of compression of the spring and the material of manufacture. If there is only one spring, the tuning limit will be one. If the manufacturer has provided several springs differing in the degree of rigidity, the device will more accurately respond to any changes in environmental conditions.

Usually, during operation, the gearbox produces noise due to cavitation, which occurs due to an increase in the head velocity at the entrance to the device.If the flow area is too narrow, then the likelihood of cavitation is very large. Therefore, when choosing a regulator, it is necessary to know the degree of cavitation and the regulated head velocity. These values can be viewed in the passport of the device.

When buying a pressure regulator is not recommended:

- To buy a device on the market, where all parts are laid out on scrap flooring. This means that the equipment is counterfeit and fairly inexpensive.

- Included with the product must be a passport and a certificate of quality. Otherwise, you should refrain from purchasing a dubious device.

- Acquire a device that is designed for other operating conditions.

Installation

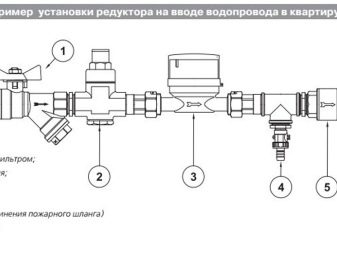

The rules that establish requirements for water supply and sewage systems indicate that the installation of water pressure regulators is performed at the input after the shut-off and control valves to the recording devices. In this case, the gearbox will provide full protection for all hydraulic household devices, including the water meter and filtration units.

In order to optimize and measure the pressure in the main water supply system and in order to avoid failures in the water supply system, it is recommended to install a special gearbox.The device for the apartment will also allow you to avoid possible damage to the equipment due to hydraulic shocks.

The reducer is mounted to the riser behind metering devices and a cleaning filter. It is highly recommended that the water supply system be horizontal and the gearbox between two valves. The pressure regulator is installed vertically, since installation in a horizontal or inclined position is unacceptable.

The installation of the gearbox is no different from the installation of a water meter or a cleaning filter. The direction of water flow is indicated by an arrow on the instrument body, and a pressure gauge or socket for its location is located in the upper part of the regulator.

Before installing the gearbox, work should start with water shut off, and if necessary, install inlet shut-off valves, where a mechanical cleaning filter element is attached. You also can not forget about the ball valve, which is mounted on the membrane tank regulator.

Conducted thorough sealing of all joints. In order not to damage the gearbox, it is desirable that all sealing operations be carried out by tow, thus avoiding the formation of leaks.

Devices for private households are designed to perform the same function as for apartments. Only for the water supply of private houses pumping stations are used. Gearboxes are installed at the point where the home network is connected to the pipeline. You should also take care of the cleaning filter, which is mounted on the input to the home pipeline. Before the pressure regulator at the pump station and after the shut-off valves are installed.

Adjustment

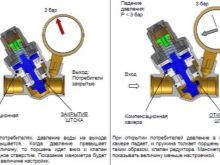

The most optimal head is 2-4 kg / cm2. Since this is very difficult to achieve, it is necessary to understand the process of adjusting the pressure reducer.

Different models of regulators differ in speed of action. With leakage, the energy of the head decreases by 1.5-1 bar. After some time, the pressure rises and becomes just below the static value. The optimum water pressure at the outlet should have a value of more than 1.5 kg / cm2 less than the value at the inlet. In the opposite case, this will lead to a slow movement of water in the water supply system.

The manufacturer makes the initial setup of the device. Household regulators must have a standard pressure of 3 atmospheres.In that case, if the working pressure of the plumbing system does not coincide with this value, it is necessary to independently adjust the parameters.

Adjusting the gearbox depends on the pressure gauge. Turn the adjusting screw until the gauge starts to show the test values. Such a screw is mounted on the body of the compensator. You can rotate it with a hex key. When turning in the direction of increasing or decreasing pressure, the spring is weakened or compressed, which presses on the piston or valve.

If a nest is not provided for the pressure gauge in the regulator, it is mounted separately on the water supply section. The network load pressure must comply with the accuracy class of the instrument for measuring pressure and the range of measurements. The error of parameters will lead to the deterioration of household equipment.

The adjustment process is as follows:

- valve opening;

- the closure of all points of water intake;

- setting the required pressure value;

- opening water intake points and checking the pressure gauge.

Adjustment of the gearbox is carried out with a working network and the presence of water pressure.Thus, it is possible to notice the difference in the parameters on the manometer after unscrewing with the adjusting screw. The adjustment process is not recommended in the absence of a pressure gauge, as this may lead to a failure of the instrument's factory settings.

Tips and tricks

In the process of installing a pressure regulator for water, you must adhere to the following recommendations:

- automatic valve must be in a heated and accessible place;

- the instrument case must be isolated from outside pressure;

- the arrow on the regulator must correspond to the direction of water flow;

- Before installing the device, it is necessary to remove dirt, silt and scale from the pipes;

- installation of the mesh filter will provide improved operation of the device;

- stop valves are installed for maintenance, disassembly and replacement.

The poor performance of the pressure regulator can be noticed if there are paired pressure gauges or the water intake point is before the gearbox.

The maintenance of the gearbox consists in flushing the built-in filter element and the gearbox itself. If these procedures do not give any results, it is possible that a mechanical failure has occurred or the elements have deteriorated.The condition of the mechanism can only be determined by removing the stem.

For information on how the water pressure regulator should work, see the video below.