Wellhead: selection and installation process

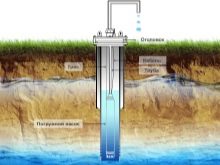

Many people today live in the private sector or in suburban areas. And the provision of various benefits of civilization in such places is not always the maximum. For this reason, it is often necessary to use various methods in order to gain access to some things that have long been considered elementary. And it often happens that the only source of water is the so-called wells.

But in order to start using it, it is necessary not only to drill it, but also to properly equip it technically. Therefore, it is worth paying attention to such a thing as the tip.

Special features

A wellhead is a device that overlaps the casing in its upper section, which helps protect the wellhead from being hit by foreign objects. It also performs functions like:

- allows you to create a reference point for the subsequent suspension of the submersible pump, as well as the nodal connection, with which subsequently it is easy to connect a plastic pipe;

- the creation of the so-called closed plane, which forms the bottom of the hole, casing tube, as well as a borehole tip, which has a sealed contour, allows the pump to create a certain amount of vacuum in the volume, due to which the water flow increases significantly;

- sealing of the inlet from precipitation of various kinds, as well as impurities in the form of debris and soil, which eliminates the need to build a house for the tip;

- protection of equipment from vandals. This function is carried out due to use of special fixture. This protection will not provide any house with any type of barn lock;

- increase in well flow;

- reducing the likelihood of freezing of the well top in the winter season;

- performs the function of a simple adapter with pipes with a larger diameter and a smaller diameter.

It should be noted that the wellhead for the well copes with a large number of tasks of various kinds and makes it possible to solve a huge number of problematic issues faced by the well owners.For the selection and installation of a wellhead for a well, knowledge of the device and installation features is necessary.

Kinds

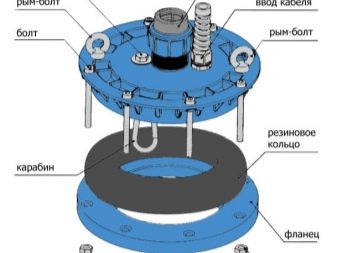

Today it is easy to find on the market several categories of tips for a well. Their device is almost the same and consists of a flange, a cap, and a ring of rubber. The difference lies in the material that was used to create the tip, as well as in the additional properties of the operation of this part.

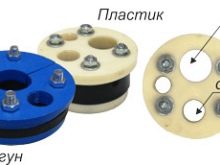

Most often they are made of either metal or plastic. If we consider the metal cap, it can be made of either steel or cast iron.

First of all, the difference between metal types and plastic is, at least in the mass of equipment that is suspended. Plastic cap can withstand weight up to 200 kilograms, and steel - up to half a ton. When choosing the material of the tip, one should take into account the depth of the well, as well as the weight of the equipment that will be attached to it.

For example, for wells whose depth does not exceed 50 meters, the weight of the equipment will not be more than 50–100 kilograms. At the same time, for deep wells, where it makes sense to use a powerful pumping unit, as well as several tens of meters of steel cable and wires, and the total weight of the equipment can exceed a quarter ton.

The wellhead has a number of options, because manufacturers are trying to satisfy the requirements of all their customers. For this reason, well heads are completed with the following parts:

- eye bolts;

- cable entry, which is necessary for the electric drive;

- the union for a pipe from which water will fall;

- a set of carbines;

- bolts for fasteners.

Now about some elements worth mentioning in detail.

- Eye bolt It is an ordinary bolt, the upper part of which is made in the form of a ring. These elements are usually used for hanging equipment, attaching cables, and so on. As a rule, they are placed on the tip, so that the lid is easier to raise and below so that you can hang the pump.

- Cable entry - This is a great thing, the presence of which virtually eliminates the possibility of accidental damage to an electrical cable. As a rule, such an input has a special spring, which provides a secure fit and allows you to say that the tip is sealed.

The bolts that connect the flange and the cover can be a special design that allows you to maximally protect the tip and the well from unwanted interference.

Blueprints

For the headboard is extremely important such a thing as size.More precisely, we are talking about such a parameter as the diameter of the tip. This feature is fundamental when choosing a device. To date, well casing pipes are selected based on the installation of deep-well pumps in them, whose diameter is quite large. Accordingly, the diameter of the tip may vary. The most common sizes are 90, 125 and 159 mm.

It should be said that the price of the cap is formed depending on the material from which it is made, and its diameter. It is worth paying attention to the marking of tips, as it usually encrypts the basic technical properties of this product.

Today on the market are the heads from such manufacturers as "Dzhileks", Merrill, "Aquarius". The name of the caps of these and other manufacturers usually states the following: cap borehole OS 125-32 or GSP 90-110 / 25.

The decoding marking will be as follows:

- the abbreviation "OS" means the borehole cap;

- 125; 90–110 is the diameter of the casing for which this tip will fit;

- the numbers “25, 32” and others at the end mean the diameters of the adapters for the water supply pipes;

- the letter P means that this particular model is made of plastic. If this letter is absent, then it automatically indicates that the cap is made of steel or of cast iron.

Important: some models are universal in the issue of casing diameters, they can be installed on pipes with a diameter of 140 to 160 mm.

Installation

Now it’s worthwhile to dwell on how to install the cap for the well with your own hands. In the context of the fact that the design of the tip is extremely simple, it can also be installed without any special problems. But still there are certain rules that should be observed in the process of installation work.

The order of work will be as follows:

- preparation of the edge of the casing;

- the flange is put on the tube in such a way that the side looks down;

- installation of the sealing ring;

- fixing the pump cable;

- electric cable is passed to the corresponding input;

- A part of the waterfall pipe or a hose is attached to the fitting, and the second end of the pipe is attached to the pump;

- the pump is lowered into the well;

- now close the lid by the mass of the submersible pump;

- the flange and the cover are connected with bolts that tighten evenly.

The preparation of the edge of the casing starts with the fact that its edge is trimmed clearly horizontally. This makes it possible to place the tip in a plane perpendicular to the casing. When the pipe was cut at the right level, its edge must be carefully polished. You can use the usual grinder with the appropriate set of nozzles.

Before mounting the tip, the metal casing will not prevent further processing with special paint on metal. This is done for greater protection. The sealing ring is sometimes difficult to put on the casing, which is why it is extremely difficult to push it down. To solve this problem, you can use a lubricant.

Many people want to get water from the well almost immediately. For this reason, some owners immediately lower the pump, postponing the installation of the tip. So do not follow. First, the flange and sealing ring are put on, after which the pump can be lowered into the well. Otherwise, to install the tip, you have to get it, then lower it again.This is also not the best solution, because the risk of damage to the column and equipment increases. Yes, and the complexity of the procedure is too great.

Now attach the cable to the pump. This can be done with special carbines. The length of the cable must fully comply with the depth of the equipment. There is no need to lower the pump until all the other elements are located in the corresponding connectors of the top cap. There is a special clamp on the hole for the electrical cable, which should be loosened so that the cable can slide freely. If the wire is pinched or incorrectly located, it may break.

Now the lower end of the hose is attached to the submersible pump, after which you need to fix the water-drop pipe or hose on the tip. When the pump is lowered into the well, the cable should be released gradually and carefully. When the equipment is lowered to the required depth, the lid should be closed so that the weight of the pump pressed it against the flange. In this case, the seal will be in a special groove and will be pressed tightly against the casing, which will ensure reliable sealing of the whole structure.If the head was mounted correctly, the sealing ring will be evenly pressed by the flange to the cover, and the connecting holes will be located opposite.

If this effect was not achieved, then it is necessary to look for the cause. It may be necessary to slightly change the position of the cover. Connecting screws must be tightened as evenly as possible so that there is no any bias to one side. There is no great need to try hard.

Too tight connection of the cover with the flange can cause damage to the rubber ring, which will lead to a violation of the tightness of the structure. But a very weak compound should not be made either.

If the bolts are not tightened too much, then the cap can be simply removed from the pipe, their installation simply loses its meaning.

If a cable with a heavy pump is attached to the top cap, then it will be best to install it together, so as to gently lower the pump into the well and replace the cap. When the cover is installed and fixed, it is almost always possible to observe the slack of the electrical cable.For this reason, the wire must be selected so that it does not sag, but is not too tight. Now you can connect a water pipe to the fitting. Then, the pump is usually turned on, which allows to assess the correctness of the installation of the tip and its condition under the operating load.

Manufacturers

If we talk about manufacturers of tips for wells, today on the market you can find products of both domestic and foreign manufacturers. WITH“Aquarius” and “Dzhileks” should be singled out among domestic companies, and if we talk about foreign manufacturers, you should pay attention to Merrill.

- Company "Aquarius" It is one of the most well-known manufacturers of tips for wells and similar equipment in general. In the assortment of the company there are various models of caps, both plastic and metal. This allows customers to purchase a solution that is ideal for their well specifically for all its features.

- Company "Dzhileks" It is not the first year that it has been producing high-quality tips for wells. It produces exclusively cast-iron and plastic solutions that can be used in various types of wells and ensure their high-quality and stable operation.If we talk about which company's products are better, then this cannot be answered unambiguously due to the fact that all the solutions of these companies are high-quality.

- The choice depends more on the well itself and the features of its work. There are other solutions on the market from domestic manufacturers. For example, the model "Watercolor" from the company Unipump. This model is universal and suitable for casing wells with different diameters. Such cast-iron solutions such as “Aquarebot” have long gained fame as reliable devices to ensure the high-quality operation of wells.

- Company Merrill located in America and manufactures plastic and cast iron caps to foreign standards, which is a guarantee of the highest quality and smooth operation. Merrill models are respected by customers and buyers in the first place for the stability of their work. It is known that they rarely need to be repaired and can work even in rather difficult environmental conditions or under the influence of very serious loads. In general, today the market can find a lot of both domestic and foreign tips for wells,which allows almost everyone to find a solution that will allow the well to work smoothly and ensure the normal flow of water into the house or building.

Tips

It should immediately be determined from which material the tip is needed, because each has its own advantages and disadvantages. For example, cast iron has great weight and high strength. He also has a maximum resource. At the same time, the price of such products will not be too affordable. If we talk about steel, such models have an average price and high strength. But they need additional corrosion protection. Polymeric options are available to everyone, but their strength is extremely low.

Important factors by which you can select the head for the well are the following:

- pump weight For heavy models it is best to use cast iron solutions. And the strength of polyvinyl chloride modifications will be enough to withstand the weight of vibratory household pumps;

- material, from which the casing is made. A steel head for a well can be fixed to a column made of similar material by welding,what allows to provide one-piece connection. If we are talking about polymer products, they can be fixed on PVC columns by welding.

In addition, before purchasing equipment at the well section, it is necessary to see the loads that the head should take from the mass of pumping equipment. We are talking about the following parameters:

- well depth - with its increase, the mass of hoses, electrical cable, pipes, fixing cables will also increase. For this reason, if we consider artesian wells, then the use of polymer products in this case is unacceptable;

- column diameter - manufacturers make various products, given the range of submersible pumps, the diameter of which is the selection of the size of the casing.

These tips will be extremely important in the selection of tips for different categories of wells. In general, the process of selecting and subsequent installation of the tip for a well cannot be called too complicated. Before acquiring a particular model, it is necessary to know the criteria that will be important for the high-quality operation of the tip and well.

And also it should be clearly understood before the start of installation, how this process takes place and to adhere to a specific sequence of stages, because any change in the sequence can threaten with unstable work and, in general, the output of this device out of order. Choose a good tip for the well and install it with your own hands under the power of even a person who has not previously encountered this sphere.

In the next video you will find a review of the sealed tip for the well.