Vertical hydraulic tanks: types, subtleties of choice and installation

Vertical hydraulic tanks are a special metal container, inside of which an elastic membrane with a certain water level under a certain pressure is contained. Each buyer must learn the types, subtleties of the selection and installation of products.

Special features

A hydraulic tank is called a hydroaccumulator or membrane tank. It is used to maintain a stable level of pressure in the plumbing system. Also, the product protects the pump from wear, the drainage system itself from water hammer. At the expense of a hydrotank it is possible to use water even in the absence of tension.

Advantages of vertical hydraulic tanks:

- Protection of the pump against early wear.

- Maintain stable pressure in the plumbing system.

- Protection against water hammer that may form during the launch of alluvial equipment. Water hammer can damage the pipeline.

- Maintain water supplies in the system.

Vertical type hydroaccumulators have drawbacks, which are complicated installation. Installation will require effort and some skills.

Kinds

Vertical hydraulic tank for water supply may vary in size.

There are several types of such devices for water disposal systems.

- Traditional. Used for domestic use. The volume of products is 24-50 liters.

- Medium volume accumulator. Capacity is 80-100 liters.

- Equipment with a capacity of more than 150 liters.

The hull part of the water tanks is colored blue or green. If the expansion tank is red, then such products are used for heating.

Materials

The membrane tank can be made of two materials: enameled steel and stainless steel. Spare parts for hydraulic tank are made of different materials.

The following raw materials are used for the manufacture of the membrane:

- Natural - rubber;

- Butyl is a type of artificial butyl rubber;

- EPDM is the most common material of artificial origin;

- SBR - raw materials used in expansion tanks for the heating system;

- Nitril - this material is used in the event that the pear hydraulic tank is not in contact with drinking water.

Volume

Most often purchased accumulators, the volume of which is 50 liters. Such parameters are enough to serve a family consisting of 3-8 people. Performance indicators should not be more than 3.5 cu. m per hour

If there are more than 8 people living in a family, you should purchase a product that exceeds 100-150 liters.

Some users choose equipment for 80 liters, which is not enough for normal operation.

Also on sale are hydraulic tanks, the capacity of which is 200-300 liters. They are suitable for mass consumption of large amounts of water. Often such products are used in enterprises.

Principle of operation

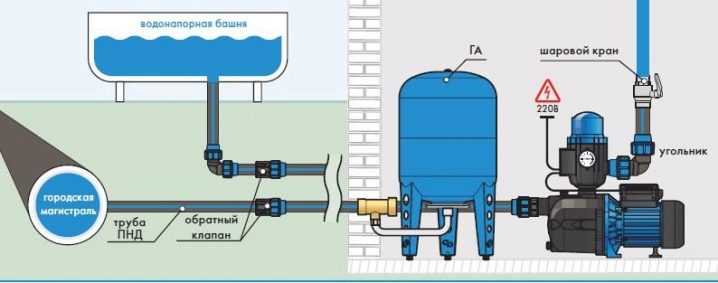

The device operates as follows. The pump delivers pressurized water to the hydraulic tank pear.When the pressure threshold is reached, the relay turns off the pump and the water supply stops. After the pressure drops, the pump automatically switches on with a further supply of water to the membrane.

During the operation of hydroaccumulators, the air dissolved in the liquid accumulates in the membrane. This action reduces the performance of the device. For this reason, it is necessary to carry out preventive work, consisting in the discharge of accumulated air masses.

Famous manufacturers and reviews

There are several manufacturers that are in high demand among buyers:

- Aquasystem. This is an Italian brand that sells quality products. Hydrobags of the Aquasystem Vav, VAO 24 series are in demand. Users note the performance of the equipment, its reliability and long service life.

- "Aquabright GM" - this is a domestic trademark, the production of which is carried out in Poland. The company produces hydroaccumulators of vertical and horizontal type, which can work in hot and cold water supply systems. Customer reviews report on high-quality components and affordable price category of goods.

- Stout - These are hydraulic tanks, which are developed by Russian and European specialists.The equipment is famous for high quality, performance and ease of installation. Users are attracted by the affordable price category of products.

- Unipump - is a domestic brand. Membrane tanks are made of stainless steel, which does not corrode. Buyers often make a choice in favor of this manufacturer, since the brand offers high-quality and reliable hydraulic tanks for water supply systems.

- Unidzhibi. This is another Russian company that produces hydroaccumulators for water supply systems. Buyers choose the manufacturer, leaving positive comments about the quality of products, cost and performance.

Which is better to choose?

Before buying, you should decide for what purposes the hydraulic tank is selected, as well as with what volumes of liquid it has to work. If the equipment is installed only to support a certain water pressure, you can use the hydraulic tank, the volume of which is 24 liters. In this case, it is allowed to connect only three water points (kitchen sink, washing machine, bathroom).If the number of points increases, you need an additional device.

To eliminate large loads, you need a hydraulic tank with a large volume.

A 50-liter product will be required to compensate for insufficient water during peak use. If the equipment is intended for backup use, then you should pay attention to the capacity of 100 liters.

In addition to volume, it is necessary to correctly determine the pressure in the tank when there is no water in it. This indicator is located on the body of the device. To raise the liquid through pipes with a height of 10 m, pressure is required, the value of which is 1 bar.

If the hydroaccumulator is located in the basement, then an additional 1 bar must be added - the excess is required for unobstructed pumping water to the first level of the building.

How to install and connect?

Installation of the hydroaccumulator should be carried out in compliance with all the rules that are described in the technical documents. Before installation, you need to fix all the contraindications to the installation and make sure that the equipment will work.

Below is the installation instructions for the hydraulic tank.

- It is necessary to control the pressure of air masses in the tank. The indicator should not be less than 0.2-1 bar from the value indicated on the indicator.

- For installation, you will need a fitting with five outlets, a pressure level regulator, a pressure gauge, FUM tape, tow and a sealant.

- Then you should connect the fitting to the tank. This process can be performed through a flange or rigid type hose.

- The fitting must be attached to the fitting, which will measure the pressure, as well as the pump tube with a relay-regulator.

- Then, remove the cover from the relay and connect the pump cord to the “pump” contact. In the contact "network" is required to connect the power cord. If there are no marks, it is not allowed to connect the device without the help of a specialist.

- Need to take care of the security of the device. All leaks are prevented by using FUM tapes or tow, which are applied to the threaded connection.

- Then you can turn on the pump and check its functionality. When water begins to flow into the tank, you should carefully examine the connections and make sure there are no leaks.

- To minimize noise and vibration during operation, it is necessary to use a stable foundation.

For more information about vertical hydraulic packs, see the following video.

Tips

To eliminate errors in installation and operation, It is recommended to use the advice of experts:

- in the room where the tank is installed, there must not be sub-zero temperatures;

- the doorway should not interfere with the dimensions of the hydraulic tank;

- it is not allowed to put a vertical type hydraulic tank horizontally;

- maintenance and preventive maintenance will require a sufficient site;

- installation of products with external damage is not allowed;

- it is impossible to carry out installation if the place does not meet the requirement of producers;

- it is unacceptable to install if the area under the accumulator is not able to cope with the mass of the filled tank;

- it is not necessary to start installation if the device leading to it exerts loads on the hydraulic tank;

- for the device should be provided with water drainage;

- product must be protected from external influence.