Thin insulation of the walls in the apartment: the characteristics of materials and installation methods

Protection of the room from external noise is an actual problem for residents of apartment buildings. To solve it, the modern construction market offers a wide range of noise insulation and sound absorbing materials. Thin insulation is one of the effective means of protection. It allows you to securely protect the home from extraneous sounds.

Special features

Unlike thick sound-insulating materials with a soft structure and a sound absorption coefficient of up to 0.95 units, thin materials are distinguished by a lower figure. Its value usually does not exceed 0.5 units. The coefficient of foam and polystyrene foam is 0.25 units and corresponds to class E.To ensure good protection it is necessary to use materials not lower than class C.

With a high level of extraneous noise, thin soundproofing materials should be used as part of multilayer structures. In the case of moderate noise and inappropriate installation of a thick panel to use such materials is quite acceptable. Noises are divided into three types. They are:

- structural;

- shock;

- by air.

The use of thin sound-proof materials is able to protect the room only from airborne noise. These include:

- barking dogs;

- vacuum cleaner and television;

- crying baby;

- conversation and singing.

The measure of the degree of protection of material from airborne noise is called the sound insulation index and is denoted by the symbol Rw. The higher the numerical value of Rw, the higher the insulating properties of a particular material. Shock and structural noises have a different origin and wavelength. Therefore, to cope with them with the help of thin noise isolation will not succeed.

Advantages and disadvantages

The popularity of the use of thin sound insulation due to a number of positive properties:

- Significant savings in room space due to the small thickness of the material. After its installation, the area of the room is practically unchanged.

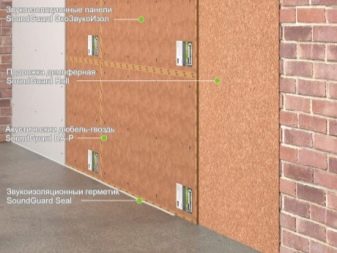

- Easy installation is due to the lack of need to install a metal frame, laying thick plates and the subsequent plating of the structure with sheets of gypsum boards.

- A wide range of materials with different sound insulation index indicators facilitate the selection of the desired type.

- Ecological safety of noise-insulating materials is achieved due to the absence of toxic substances in their composition.

- Significant reduction in terms of work compared to the time required for the installation of other types of insulation.

The disadvantages include the high cost of some models and the low efficiency of thin materials. Many of them should be used only in conjunction with other types of noise insulation.

Classification

According to their performance and purpose, thin materials are divided into two classes.

Sound absorbing

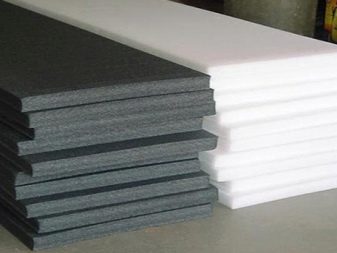

They convert sound energy into heat and significantly reduce the intensity of the reflected wave.These are fiberglass and basalt slabs, which can be attributed to thin types of noise insulation only conditionally. Despite the fact that the minimum thickness of sheets is 3 cm, their installation requires the installation of a frame with further lining sheets GKL. As a result, the thickness of the structure exceeds the values that fall under the definition of fine sound insulation.

Polyurethane foam panels, which are called acoustic foam rubber, do not require frame installation. They are mounted on the base with glue. The advantage of using this material is that there is no need to level the wall before sticking. The minimum thickness of such a panel is 3.5 cm, which makes it possible to attribute this type of sound insulator to a thin type.

Another popular tool is liquid sound insulation, which belongs to sound-absorbing products. The material is applied to the wall and closed with a decorative panel or gypsum board. The thickness of the applied layer should be at least 3 cm. The thinnest representative of sound-absorbing materials is a roll tube, its thickness is 0.8 cm. This type of sound insulating material is considered universal.

With it, you can reliably protect the room from extraneous sounds, effectively decorate the space, using the material as a decorative coating. When choosing a cork sheet should be aware that the diameter of the crumb should not exceed 3 mm. Models from a crumb of 6 mm are slightly inferior in sound-proof qualities to fine-grained material. Therefore, you need to choose the material carefully.

Soundproofing

These types of sound insulation block the path of the sound wave, not allowing the sound to penetrate the room. The most common materials of this type are GCR and GVL. However, they should be mounted on a relative basis, leaving a gap between the cladding and the wall for filling with sound-absorbing tiles of at least 3 cm. As a result of the multi-layer construction, the total thickness of the “cake” can be 4 cm. This is a conditionally thin type and .

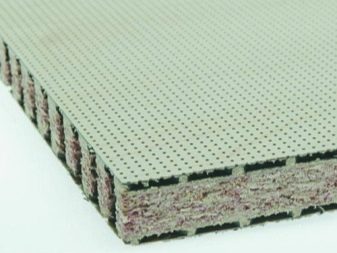

Decorative panels are quite effective type of noise insulation. Therefore, they are in demand among consumers. The sheets have a layered structure, they are made in the form of a cardboard frame with mineral filler inside.Quartz sand is often used as a filling material, which makes it obligatory to glue sections of panels with adhesive tape when they are cut. This is practically the only drawback of this material.

Thin materials include some models of acoustic plates made of soft fiberboard with a thickness of 1 to 3 cm. The panels have a multilayer structure. They consist of a reinforcing mesh, polystyrene foam and waterproofing. This type of wood and decorative plates of wood fiber with a thickness of 1.2 to 2.5 cm.

Ultra slim

On the modern market of building and finishing materials there are a lot of ultra-thin films and membranes that can intercept the sound wave and neutralize it. The sound insulation characteristics of the membranes are directly dependent on the frequency of extraneous sound. They differ from each other in a critical frequency. This is the name of the smallest frequency, after which the sound insulation properties of the material are reduced.

Of building materials, concrete and bricks have the highest critical frequency. Good performance in rubber and steel, the best has lead. However, due to its harmfulness to the human body, it is not used in the manufacture of insulating membranes.A polymer-bitumen membrane has a critical frequency comparable to lead. In contrast, it does not contain harmful impurities, does not adversely affect human health. The material has a polypropylene coating, its total thickness is only 0.4 cm.

Mineral membranes have good performance characteristics. They are one of the thinnest representatives of noise insulation, their thickness ranges from 0.25 to 0.37 cm. Among them, the most famous are the aragonite variety (Teksaund) and the barite mambran (sound block or loaded vinyl). The coatings include polymers, which give the films high elasticity and plasticity.

Popular means of sound insulation are polyethylene coating for wallpaper 0.5 cm thick and lead foil 0.7 cm thick, covered with a polyurethane foam layer. Wallpaper ultrathin laying is made from the made foam polyethylene wrapped by the thermolamined sheets. To ensure the best sound insulation performance, multi-layer use of membranes is recommended, alternating them with noise absorbers. Of liquid materials is to provide Green Glue with a viscous structure.It is applied on the reverse side of the plasterboard before installing them. While hardening, the substance creates a reliable barrier to sound waves and provides good sound insulation of the room.

Kinds

Among the most popular and frequently used materials are several varieties.

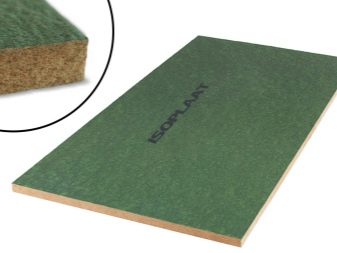

Isoplaat

This is a natural, environmentally friendly soundproof plate, which consists of softwood fibers. Sheet size is 2.7 x 1.2 m with a weight of 4 kg and a thickness of 1 and 2.5 cm. The Rw index corresponds to 23 dB, which is a good indicator for a material of this class. Installation of the plate is carried out with the help of glue. The material is characterized by good ventilation. The front surface has a smooth texture, the material is suitable for finishing the walls of an apartment and a wooden house.

Kraft

Kraft is an environmentally friendly fibreboard, covered with wax paper on one side and corrugated cardboard on the other. The size of such a plate is 2.7 x 0.58 m with a thickness of 1.2 cm and a weight of 5.5 kg. The Rw index is 23 dB. Plates are often used as a finish.

"Eco Soundproofing"

"Eco Soundproofing" is a seven-layer material made of cardboard and quartz sand.It is produced in the dimensions of 1.2x0.45 m. It has a panel thickness of 1.3 cm. The Rw index corresponds to 38 dB, and is mounted on glue for gypsum boards.

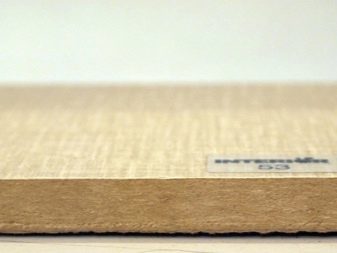

Isotex

It is durable, flexible and resilient sound insulation panel. It is made with the addition of coniferous wood fibers. Sheet thickness varies from 1.2 to 2.5 cm, weight is 1.2 kg, dimensions - 2.7 x 0.58 m.

Installation

The most common and simple option for thin sound insulation is to install a polyethylene substrate for wallpaper. Initially, the foundation should be prepared. To do this, remove the protruding elements from the wall, then putty for large cracks and chips. It is not necessary to bring the surface to an ideal state: the sound insulation will hide minor defects well.

After the surface preparation is completed, the material needs to be cut into strips of the desired length and glued to the rough substrate without overlap. Glue the material you need a means for heavy wallpaper.

During the installation of sound insulation should strictly observe the temperature. The room should not be less than 10 degrees, the humidity should not exceed 75%.

After the film is glued, you need to leave it until it is completely dry, eliminating the likelihood of drafts. Then you can proceed to the sticker of any wallpaper, including varieties for painting. Thin noise isolation allows economical use of space. It serves as the basis for finishing and effectively protects the room from moderate noise.

How to install a thin noise insulation, see below.