Features of the choice of fittings and PVC pipes

This article discloses information about sewer and water connectors. In addition, here are recommendations that will help make a competent choice of PVC fittings and other polypropylene products used for the equipment of the water pipe.

There are several different pipe options on the market today.which are made from copper, plastic and other materials. Polyvinyl chloride products, including polypropylene, in this case are considered the most affordable, so these pipes are quite common.

What it is?

When mounting metal-plastic pipes, special connecting elements are used, called fittings,they allow you to correctly lay the pipeline wiring with tightness in areas with different transitions, all kinds of turns, a diverse type of branching.

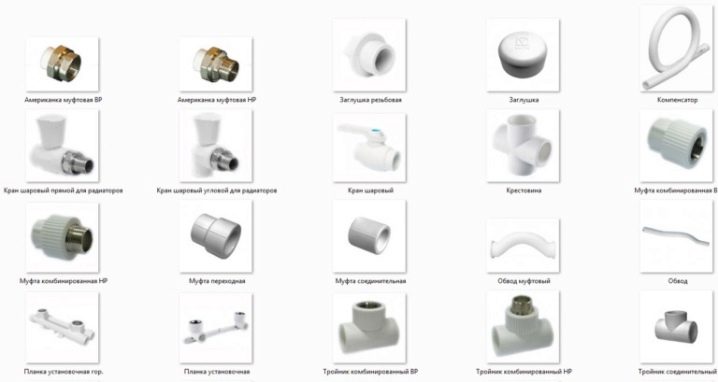

Parameters such as destination, shape, size and type of pipe affect the choice of the required connector:

- gon;

- American;

- coupling;

- or tee.

Classification

Today, there are only two different types of fittings that differ in their shape.

That is, a straight fitting is those elements that are used in connecting sections of pipes with an equal diameter, but a transitional fitting is used when it is necessary to fasten products with a separate diameter.

According to the method of mounting types of fittings can also be divided into compression, press fittings, threaded and collapsible.

In turn, collapsible products are conventional or reinforced. Fittings are made of plastic, steel, brass and copper material. Usually special press-fittings are used for metal-plastic pipes or collapsible fittings can be used. Meanwhile, the collapsible type is used for those connections that need to be easily assembled or, conversely, disassembled.

Press fitting involves only a one-time installation, and the installation itself is produced using a steel sleeve that is put on the pipe, only this way it is possible to provide a fairly reliable fixation.

Separate attention deserves a new kind of connection, which is called an American. A distinctive feature of such an attachment is the simplest and most convenient installation, that is, when using an American, the connection of the aqueduct is easily and effortlessly provided.

American is a split type of connection, during the installation or dismantling of which only the flare nut can be rotated, all other parts of the pipeline in the meantime should be fixed.

Fitting

Usually CPVC pipe fittings are used for non-pressure type of pipeline, which is located in the sewage of the modern type, when equipping pools, because only this system has high reliability and durability, besides, it is resistant even to the effects of household chemicals.

Select the fittings should be based on their purpose, that is, there are fittings that can be used for external or internal use.

For example, fittings specifically designed for outdoor sewer systems., have high heat resistance, these products of terracotta color, among other things, are reinforced with special additives. But the fittings, which are used only in the system of the internal type, are usually painted in gray.

You can use the following kind of plastic fittings:

- The classic type of coupling is a small piece of pipe with two sockets capable of combining two separate parts of the pipeline;

- T-shaped tee;

- elbows for connecting the angular type - is a separate segment of the pipeline, usually curved at 90 degrees, 67, 45, 30 and 15;

- reduction for combining pipes with different diameters;

- tee with a lid is comfortable and removable, it is necessary when checking the condition of the entire plumbing system as a whole;

- check valve type, which will be needed to regulate the movement of water itself through the pipeline itself;

- cross connection for cross-type connection;

- compensation pipe, which will be needed only when you need to make a fit along the entire length of the vertical pipe located in the riser.

Polypropylene communication

With particular care should be taken to the choice of compounds that will be needed for polypropylene pipes, because they are made of plastic material or from a low-melting thermoplastic.

Accordingly, compression type fittings are considered unsuitable., since these products are capable of deforming the pipe in the zone of compression (fastening). All this will lead, in turn, to an irreversible leak, in the meantime threaded fittings like Americans will be perfect. Since the American is assembled from the coupling with a special cap nut, it will be possible to assemble and disassemble the corresponding sections of the pipeline quickly and easily.

The following types of fittings may be used:

- coupling coupling type, which is required for smooth welding of individual pipes with the same diameter;

- adapters, connecting pipes of different diameters at the end;

- couplings with thread inside and outside, they are needed when connecting the threaded fitting;

- taps for different turns with the necessary transition to other dimensions;

- American woman is used if you need to collect a certain segment of the pipeline immediately;

- Tees are of various types, namely: with external or internal thread, there are also corner tees;

- the crosspiece is used when it is necessary to solder four different pipe sections at once;

- detachable connector type;

- plug, that is, the sleeve - is used if it is necessary to close the pipeline;

- contours are used if it is necessary to circumvent existing obstructive bends at an angle.

Due to the geometrical connection it is possible to install fittings and pipes using thermal welding.

The classification of the polymer elements of the compound is made according to the following criteria:

- by installation method;

- in form;

- on the production technology.

Plastic fittings are segmented or cast, everything will depend on the technology of manufacturing these products.

Cast constructions are called, respectively, monolithic products that do not have connecting seams. The fact is that this product is made as follows: molten polyvinyl chloride is poured into special forms with a specifically defined configuration.

But if we talk about segment fittings, they are made of PVC pipe segments that are soldered together, the configuration of this product has seams, and this affects the strength of products. All NPVH fittings are made of molded ones; meanwhile, products manufactured for the internal type of water supply can also be segmented.

Installation of glue fittings

Glue compound is also called chemical or cold welding. To implement this technique, you need to use a special glue, which is an emulsion from a solvent plus polymer molecules dissolved in it. The use of cold welding makes it possible to achieve a permanent joint, since when fully cured, the glued joint has the same characteristics as pipe fittings.

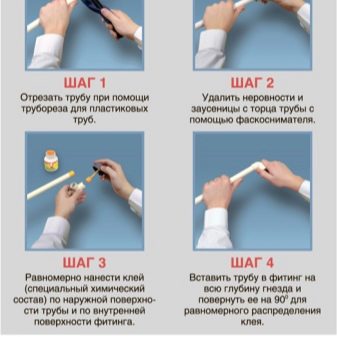

Perform work you need on a strictly defined technology

- The pipe should be cut perpendicular to its own axis, for such work it is better to take a special roller pipe cutter. Of course, the grinder is also used, it is possible to use the fine-toothed type of hacksaw, only it will have to do an even cut on its own, because this is what the reliable future connection depends on.

- At the end, with the help of a face picker, the desired type of chamfer is formed, and the angle should be 15 degrees. This stage is considered mandatory, if you ignore it, the risk of scraping glue from all contacting surfaces increases.

- The tape measure is necessary to measure the depth of the body at the fitting, it also helps to correctly mark the boundaries of the entry on the surface of the pipes.

- An ordinary napkin or cloth is impregnated with a means prepared in advance for degreasing surfaces, in order to clean the pipes and fittings inside from all sorts of dirt. Next, you need to dry the treated surface, that is, leave it for a few minutes.

- Within the pre-set mounting marks, glue can be applied to the walls of pipes, the main thing is to do this evenly, the brush should be moved longitudinally. In the same way all internal walls are glued.

- Next, you should insert the pipe and check that it should get right up to the stop as far as the fitting, and here it is important to avoid the mutual rotation of the individual components at the docking stage. Products are combined, only now the pipe needs to be rotated, the rotation must be equal to орота turn, so the adhesive mass will be distributed over the entire surface evenly. Perform the procedure of applying glue, as well as the subsequent docking, you need within 20 seconds.

- After firmly tightening the interconnecting structures, it can be wiped with a cloth to remove all the excess glue that was squeezed out of the gap when joined.

Soldering fittings

To mount PVC products in this way, you need to use a special soldering iron. In this case, you should choose a tool that has special nozzles, they must fully comply with the diameter of all the parts to be joined. Each household soldering iron has nozzles for a pressure pipe with a diameter of 16-43 mm, which are included, if there are no nozzles, no problem, the necessary nozzles are purchased separately.

Consider the process of soldering.

- For the equipment of the soldering iron, the instrument is first installed on a flat surface, only after that the nozzle of the required dimensions is installed. Next, the soldering iron is connected to the mains, the soldering iron should warm up to 280 degrees. The time spent on heating the device directly depends on the power indices of the instrument, on average the heating period is 15 minutes. The whole process of soldering should be performed at normal room temperature, since it is impossible to carry out such work in the cold.

- Before soldering the pipe must be cut with a pipe cutter, creating sections of the desired size, should be cut only at a right angle.It is also necessary to process the end of the pipe itself, including the inside of the fitting, with a special degreasing agent, then dry the processed pipes and fittings for 3 minutes.

- Each connecting element must be worn on the soldering iron tips that have already been heated to the desired temperature, then PVC products are kept on the soldering iron for the required amount of time. And the time of this heating process directly depends on the thickness of the walls of the PVC elements and the diameter.

- After full heating, the pipe fitting is removed from the nozzle, only after that they are joined to each other. Already connected nodes must not be turned or bent. When cooling the structure must be protected from all kinds of deformations.

You can learn more about the types of fittings for mounting PVC pipes and get valuable tips on soldering from this video.