Plastic pipes: scope and features of laying

Plastic pipes in the modern world are among the most popular and sought after, gradually completely replacing metal options. A huge number of advantages, among which high quality, durability and reasonable price make them a more acceptable option than steel or aluminum pipes.

Specifications

Due to its unique technical characteristics, plastic pipes are considered to be one of the most popular and optimal materials in the process of installing water supply and heating systems.These pipes boast impressive qualities that make them stand out against other options. Products show an impressive level of strength and durability, and their installation is so simple that anyone can handle it.

Advantages and disadvantages

Plastic is called the material of the future, as it can be used in almost any industry where it is needed. This material is now actively used in the production process of pipes for various purposes. Plastic pipes almost completely removed metal and concrete variants from the market, as they can boast indicators that are far from metal or concrete.

Consumers choose precisely thick-walled plastic options primarily due to their cost., as they are much cheaper and more durable. Having mounted a similar pipe in a heat or water supply system, you can not worry about its integrity for about half a century. As for metal plumbing pipes, they need to be changed every 20 years, as they are subject to corrosion process and spoil the quality of water. In addition, the plastic boasts minimal thermal conductivity, so that there is no excess heat loss, as well as the formation of condensate on the surface of the pipe.

Plastic is not susceptible to corrosion, which is especially good for its use in the water supply system. And due to the fact that these pipes differ in minimum weight, their installation will not be easy.

The following advantages of plastic pipes can be distinguished, which qualitatively distinguish them from competitors:

- They feature impressive corrosion resistance. Unlike steel and metal options, plastic products do not rust, do not deteriorate under the influence of water.

- Practically do not need replacement. Due to the fact that plastic pipes do not collapse from exposure to water, their replacement is required much less frequently than other options. With proper and proper operation, they can last for about 50 years.

- Guarantees high quality water. Plumbing, which consists of plastic pipes, is not subject to rust, so the water will remain clean and harmless. In addition, the water flow will not meet any obstacles in the form of calcium deposits, which provides a good and stable water pressure.

- Flexibility. Such pipes are easily located in the ground due to their flexibility, which requires minimal costs for excavation and restoration of the soil ground.In addition, when the temperature changes, plastic pipes can expand and contract, and there will be no cracks or splits on their surface.

- Differ in small weight. Transportation and installation of plastic pipes requires minimal energy consumption in comparison with other options.

Classification by purpose

Plastic pipes are a versatile material that can be used in various branches of construction and communications: for water supply, for gas, casing, for wells, ditches, heating mains, etc. There are many options in the current market depending on the purpose, which differ its properties and functions.

Today, metal and steel pipe versions for the construction of sewage systems are a thing of the past. Most experts prefer to use plastic analogues that can boast of their high quality, reliability and durability.

Among the distinctive advantages of these types of pipes are the following:

- Resistance to chemical reagents. Since pipes for sewage are regularly exposed to a huge number of chemical influences, they are reliably protected from destruction.Plastic does not deteriorate under the influence of chemical reactions, so that it can be used in almost any environment.

- Ability to withstand huge loads. Given the fact that the external part of the sewage system is placed under the ground, it is affected by the pressure of the ground. The unique structure of the plastic allows you to cope with huge loads, mechanical damage and pressure.

- Salinity resistance and quick installation. Installing a sewer outlet takes much less time than creating an entire sewer system. A distinctive feature of plastic pipes is that they can be connected without welding machine. Just insert the elements into each other using a special lubricant.

- Cost In comparison with other materials, plastic has an affordable price.

If the sewage system will be held in a private house, you will need a sewer pipe.

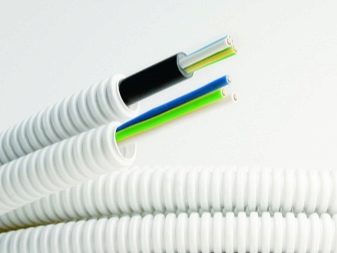

Corrugated plastic pipes are considered one of the most common materials in the construction of sewage. Thanks to their unique structure and characteristics, they have shown themselves to be excellent underground.In addition to sewage, these elements can be used in electrical wiring.

In the modern market there are several varieties of corrugated pipes. The most popular are single-layer options that are used in the conduct of the cable and the protection of the power line. As for the two-layer variants, they can be used in underground sewage systems for communication, which became possible due to the increased reliability and durability of this material.

Light versions are distinguished by their vulnerability to mechanical stress, therefore they cannot be used underground, but heavy ones can boast resistance to mechanical stress and severe loads, so they can be used even for underground utilities. If it is necessary to build communications in difficult conditions, for example, under a highway, then it is best to use super-heavy corrugated pipes.

Cast iron steel pipes for heating have long been a thing of the past. The complexity of the installation, the connection and the high cost of these materials make them unprofitable. Replaced came polypropylene, which is recommended to use because of its increased service life and reliability.A distinctive feature of this material is its reinforcement, which can be made on the basis of fiberglass or aluminum. In the first variant, the inner part of the product is formed, and the second one involves wrapping the outside.

The use of fiberglass allows you to prevent deformation under the influence of temperature difference and strong heating, without which any heating system is impossible. It should be noted that the cost of such a product is 40% higher than without reinforcement, but this does not need to be saved, since this mechanism ensures the durability of the heating system.

Among the distinctive advantages of plastic pipes for heating are the following:

- Durability. With proper selection of materials, you can forget about replacing and repairing the heating system for 50 years or more.

- Resistance to chemical processes. Plastic is largely ahead of the metal, as it is not susceptible to rust and does not deteriorate under the influence of various chemical processes.

- Due to its unique structure, the flow of water inside plastic pipes does not create noise and does not interfere with residents.

- Ease of installation. The heating system can be installed only with the help of a special welding machine, which is sometimes called a soldering iron. To carry out such an installation does not need to have special skills and knowledge. In a few minutes it will be possible to weld parts together, which favorably distinguishes plastic options against metallic ones.

- If the plastic is frozen, then you can not worry about the safety of the material and the entire heating system as a whole.

- Low price. Polypropylene and other types of plastic pipes are almost 2 times cheaper than their metal counterparts.

In the process of selecting the best option, you need to pay attention to the pressure, which is indicated next to the main marking. It is best to choose products that can withstand 25 atmospheres, since this option is suitable for most heating systems. In addition, the temperature that the material can withstand is important. For the heating system, it is necessary to choose products that are able to withstand temperatures up to 40 degrees Celsius without problems.

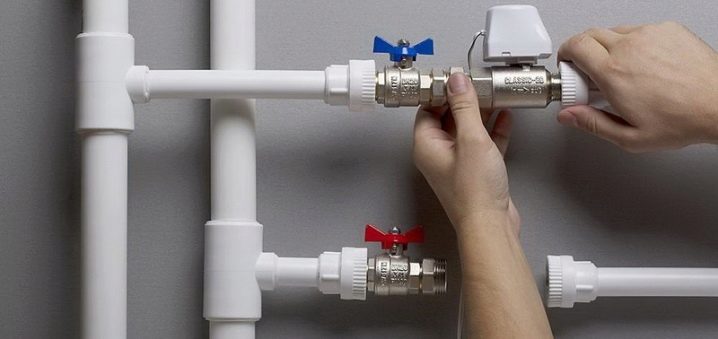

In the field of plumbing systems, plastic has also supplanted other materials. In old apartment buildings, you can still see the metal water supply system, but in new buildings such materials are no longer relevant. A distinctive advantage of a plastic pipe is the fact that it boasts corrosion resistance. Metal parts are extremely often exposed to rust, which not only reduces the service life, but also spoils the quality of the water produced, and there will be no such problems with plastic. The use of a plastic pipe allows residents to obtain relatively clean water that is not contaminated with particles of metallic materials.

In the process of selecting a pipe for the plumbing system, it is necessary to pay attention to the maximum heating temperature, which is indicated next to the marking, and also to the maximum pressure that this pipe can withstand. The design features and characteristics of each pipe depend on the manufacturer. On the modern market there are a huge number of companies that produce high-quality and reliable plastic pipes for the plumbing system.

If you need to hold hot water in a dwelling or bathroom, it is best to use polypropylene pipes that can heat up to 140 degrees Celsius and not deform at the same time. Even if the shape of the product will suffer, immediately after turning off the hot water, it will return to its former state. Hot water supply cannot be carried out without reinforcement of polypropylene pipes.

It is better to use plastic pipes for hot water, because they have:

- Resistance to high temperatures, so that they can be used for holding hot water.

- Resistance to temperature changes. The reinforced materials calmly transfer not only cold, but also hot water, without being subjected to deformation and destruction.

- Low level of thermal conductivity, so that the water remains hot for a long time.

In the process of choosing a plastic pipe for hot water, you must pay attention to the diameter of the riser, which should be from 20 to 26 mm. And when distributing from the riser to the floors, it is best to use pipes with a smaller diameter (about 12 and 15 mm). The diameter selection process should also take into account the length of the water supply, the number of floors and the approximate level of water consumption.

It is best not to try to save on hot water supply, since the use of poor quality materials can lead to problems with heating, after which you will have to buy materials again and carry out installation work.

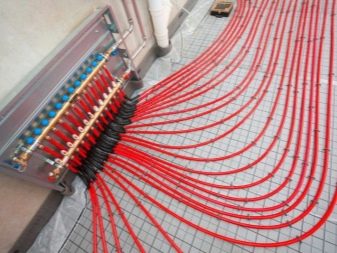

Underfloor heating is a universal way of heating a modern apartment. For these purposes, they initially began to use plastic pipes, which are distinguished by their low mass, durability and strength, which makes them an integral element of the system. It should be noted that in the warm floor water is heated to a temperature that does not exceed 40 degrees Celsius. A distinctive feature of this system is that water should be distributed evenly in order for the apartment to warm up on all sides. Very often heated floors are installed in the bathroom and in the kitchen. For installation can be used as metal-plastic, and polypropylene and polyethylene pipes.

Metal-plastic is the most affordable and alternative option. Its inner layer is made of polyethylene, and the middle of aluminum and polyethylene. As for polypropylene, it is cheaper than the metal-plastic variant, however, it is rarely used for floor heating, since it cannot boast resistance to overheating.If you want to choose this option, it is best to give preference to cross-linked polyethylene, which is characterized by increased strength, long service life and resistance to overheating.

Laying underfloor heating is a complex process.requiring a competent approach and lengthy preparation. That is why it is necessary to approach the choice of material for arranging such a system with extreme literacy and responsibility. There is no point in using low-quality plastic, as it may burst or deform, causing the entire floor tile to crack, and the apartment to be flooded.

Plastic high pressure pipes are characterized by incredible strength and ability to overload. Basically, such options are used for the transportation of liquids in oil wells, the field of engineering, in hydraulic systems. A distinctive feature of such materials is their three-layer structure, which provides incredible strength and the ability to cope with huge loads.

The composition of plastic pipes of high pressure includes polyethylene as the main component. Thanks to its presence, the products are completely environmentally friendly. The most common are pipes whose diameter is 16, 25 or 32 mm.

Among the distinctive advantages of plastic high-pressure pipes are the following:

- The minimum level of thermal conductivity. Due to this, it is possible to transport liquids without loss of temperature. In addition, this characteristic allows to prevent the formation of condensate on the walls of pipes.

- Resistance to frost, so that these pipes can be used even in the most difficult conditions. When a liquid freezes inside the outer layer is not deformed and does not collapse, so it does not need to be repaired every season.

- The small mass of the product greatly simplifies the installation process. Steel pipes have a mass that is 6 times greater than high pressure plastic pipes.

- Elasticity, which allows the material to perfectly cope with any mechanical stress and shock. Even with a huge depth of the ground is not able to damage the structure of this material.

- Noiseless flow of water, environmental friendliness and durability.

The only drawback of high pressure plastic pipes is their inability to cope with direct light rays. However, in order to eliminate this problem, pipes are often covered with a special insulating layer, recognized to ensure their protection from exposure to ultraviolet rays.

The main characteristics of plastic high pressure pipes:

- Pressure. At this indicator should pay close attention. It is defined as a brand of polyethylene, and the length of the product and the thickness of its walls.

- Working temperature. If the fluid that flows inside the pipe is not hotter than 40 degrees Celsius, then nothing threatens the pipes. It is best not to use these pipes for transporting hotter liquids.

- Diameter. Plastic high-pressure pipes can boast an impressive range of diameters - from 10 to 3000 mm. For private cottages and multi-apartment buildings, it is best to use options of 20 mm.

- Wall thickness. This parameter can vary from 2 to 6 mm. It depends on the diameter of the product and is indicated on the material itself.

It should be noted that the methods of mounting and mounting plastic high-pressure pipes are also different. Installation can be carried out using compression or electrofusion fittings. The first method is much faster and easier, since it does not require special skills and the use of specialized equipment. In most cases, it is used at home in order to connect several segments.

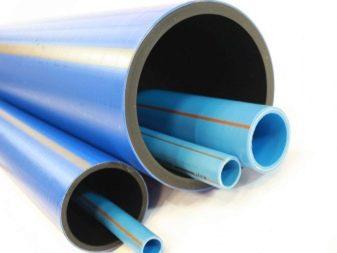

Species

As already noted, plastic pipes are among the most popular in the installation of water supply and heating systems. On the modern market there are several variants of such pipes, which differ in their properties, forms and cost.

PVC

PVC products can be used to provide water not only for the bathroom, but also for outdoor space. A distinctive feature of this pipe is high quality and durability, so that it can be used for about 50 years. Plastic PVC pipes can boast a high stiffness and a diameter that exceeds 100 mm, so that they can be used for both cold and hot water.

Such pipes are connected with fittings and special glue. Many methods of connection for such products do not exist, however, existing methods are quite reliable and durable. Among the advantages of the coating can distinguish its resistance to fire. Due to the fact that PVC is practically not burning in the air, it can be used in the bathroom or other rooms that require a minimum level of fire danger. Like its metal-plastic counterparts, PVC pipes can be used outdoors, provided that the air temperature is not less than -15 degrees Celsius.

If the air temperature is lower, the diameter of the pipe will begin to change under the influence of destructive processes. Another advantage of PVC pipe is its low melting point - they begin to completely melt at a temperature of 260 degrees Celsius and above. Like metal-plastic counterparts, PVC pipes are widely used in everyday life and industry for a stable supply of water.

Polypropylene

Polypropylene pipes have gained tremendous distribution in the field of water supply.Their distinctive feature is that they are made using polypropylene copolymer. For arrangement of a bathroom the similar product is considered as ideal option. The unique material of the pipes allows them to withstand pressure at temperatures up to 95 degrees Celsius, which ensures their incredible durability and integrity in all conditions.

If you use large diameter pipes, they are able to withstand a constant flow of any substance. with temperatures up to 110 degrees Celsius. Unlike PVC options, polypropylene pipes in the freezing process are not subject to destruction and deformation. It was possible to achieve this result due to the fact that the products can be expanded together with the working medium freezing in it, and after settling it returns its shape. Polypropylene pipes are considered an excellent option for supplying water that is heated to a high temperature. That is why it can be used when installing boilers and double-circuit boilers.

The installation of a polypropylene pipe is made by the method of mating with metal elements of networks, which can play the role of mixers,water filters or counters. For the connection, you can use special fittings equipped with metal inserts.

Polyethylene

Polyethylene versions are actively used for laying pipelines inside the premises, as well as for the continuous supply of hot and cold water. A distinctive feature of such pipes is the ease of installation. In addition, products of medium and large diameter can be used not only in the bathroom, but also buried underground, so they can be used to provide centralized water supply. These products can be both large diameter (600 mm) and medium (100 mm). The most popular is the last option, which has found active use in the process of arranging the wiring line in the bathroom.

Due to its incredible strength and reliability of HDPE, even medium-diameter products are not deformed and damaged under a thick layer of soil. In special cases, their installation can be done by attaching to the wall with plastic clips that provide maximum stability in all conditions.Regardless of the diameter, polyethylene pipes can be carefully mounted in the wall or covered with mortar. Regardless of their diameter, these pipes can be connected using bends, tees or fittings. If the pipe has a too large diameter, then it will be necessary to use a welding machine to strengthen it.

Today, polyethylene versions made of ecoplastic, in black, white and gray, are in great demand. Electrotechnical and waste pipes are flexible, so that they can be bent.

Sizes and shapes

In the process of laying modern engineering communications, close attention should be paid to the dimensions of plastic pipes. The production and use of this product is governed by the State Standards, which establish the basic dimensions of each variety. Thus, the size of the outer diameter may be in the range from 10 to 1600 mm, and also includes 34 different sizes.

In the process of selecting the product of the optimal size for the arrangement of the water supply system, it is necessary to consider the following points:

- The size of the inner diameter must be the same not only for the pipes to be connected, but also for the fittings used for this purpose.

- Nominal diameter and wall thickness.

- The length of the wall.

If you choose the right diameter of the plastic pipe and the size, then you can avoid problems and constant noise in the process of the water supply network. It should be noted that the length of the plumbing communications has a direct effect on the diameter of the elements used. If it is less than 10 m, then you can choose plastic pipes with a diameter of 20 mm. If the length of the water supply exceeds 30 m, it is necessary to install plastic pipes with a diameter of 32 mm.

It should be noted that four-meter segments are usually used for domestic water supply. If there is a large number of consumers, it will be necessary to install pipes with a large diameter in order to increase the capacity of the sewer system. An ordinary tap per minute allows up to 5 liters of water to pass through, and a 32 mm pipe is able to drive 10 times more at the same time. Plastic pipes can be rectangular, 200, 400 and 150 mm round, as well as other shapes.

Connection methods and installation

Depending on certain factors in the connection and the manipulations carried out, docking can be carried out on the basis of two categories: according to the presence of connectors and on the basis of the temperature of the process being carried out.

To date, there are several specific types of compounds:

- Connection to the socket. A distinctive feature of this method is that the end of one pipe will need to be placed in the socket of another. This method allows to achieve maximum strength and tightness due to the use of a rubber seal.

- Flange connections, the essence of which consists in the use of sleeves for flanges, which will be welded to the ends. In addition, steel flanges will need to be used. This method is actively used in cases where it is necessary to connect plastic pipes with steel or metal elements. In addition, this method has proven itself in the process of installing square structures, but this sometimes requires the involvement of corner couplings.

- Collet docking, which will be an ideal solution in the case when you need to connect parts of small diameter.During installation, you can use crimp fittings that are easy to use and do not require any special tools. In addition, these compounds can boast of airtightness, as the fitting is characterized by the presence of a rubber seal. Due to the fact that the teeth cut into the pipe with a plastic sleeve, the design will be extremely high strength and reliability.

- Butt-welding It can be used in the process of installation of the plumbing system, only if there is not much pressure or temperature drops or there are no square sections of the structure. This method is very popular in cases where the diameter of a plastic pipe is more than 60 mm. In this case, it will be necessary to use a welding machine for fastening, and the pipes will first need to be cleaned and placed in a centralizer.

- Welding electrical coupling. If this method of connection is carried out, the parts will need to be cleaned and degreased in advance, and then positioned in the same plane and put an electrical clutch on them. After this, the current is connected, as a result of which the coupling and the steel pipes are heated.After the pipes have cooled down, the installation can be considered complete. Such methods cannot be used in the process of arranging the heating system, as this may have a negative impact on the stability of the joint.

- Gluing. This type of installation can be done using conventional adhesives or by cold welding. The latter involves the dissolution of the pipe section, due to which the compound occurs at the molecular level.

- Threaded connection is very popular in the process of installing water pipes, when it is necessary to produce a combination of plastic and metal components.

Thus, plastic pipes are among the most popular and sought after on the market. Their reliability, durability and versatility favorably distinguish such pipes against the background of metal and concrete variants, and a huge range of varieties allows you to choose the best option for each case.

For how to install plastic pipes, see the following video.