Sizes of PVC sewer pipes: how to choose the right option?

PVC sewer pipes have come to replace metal products. In different parts of the sewers need pipes of different sizes. A suitable choice can be made, knowing the capacity and characteristics of the sewer pipeline.

Special features

For the arrangement of sewage drainage, pipes made of polyvinyl chloride are often used, displacing iron and steel. Plastic sewer pipes are made of ordinary and unplasticized PVC. The material includes vinyl chloride and additional additives. High strength properties allow the use of unplasticized PVC for organizing a pipeline with a pressure.

Sewer pipes are designed to remove wastewater from the plumbing., for the device of the drainage channel, installation of the intra house and street sewerage. The use of PVC products for sewage devices is justified by the technical characteristics of the material. Long service life of sewer pipelines will allow to operate the system up to 50 years. The tensile strength reaches 50 MPa, so the outdoor sewage section will withstand laying to the depth of soil freezing. The pipeline is able to function under pressure from 6 to 16 bar.

The use of polyvinyl chloride pipes for sewage has the following advantages:

- A variety of sizes and shapes of pipes and fittings will allow to assemble a sewage system of any complexity.

- Smooth internal walls do not allow sewage to settle, preventing the formation of blockages in the small diameter and preventing the pipe passage from overgrowth from sediment.

- The small weight of products and ease of cutting implies quick and easy assembly and disassembly without additional tools.

- Inertness to chemicals and corrosive effects.

- Reasonable price of elements of the pipeline.

Temperature range of operation from -10 to +65 degrees. At -18 degrees, polyvinyl chloride becomes brittle. The material is resistant to softening when heated briefly to +90 degrees.

Dimensions

Plastic sewer pipe elements are produced according to GOST 51613-2000. The dimensions of PVC pipes are determined by such factors as length, outer diameter, inner diameter of the socket, through diameter, wall thickness. External diameter assumes the nominal size of the product. The throughput depends on the bore diameter.

The wall thickness determines the strength of the pipeline, what kind of load the tube structure can withstand.

By strength class are classified:

- lightweight structures SN2 with a wall thickness of less than 2.3 mm can withstand loads of up to 630 Pa;

- moderately heavy SN4 with walls from 2.5 to 12.3 mm dependent on diameter, coping with pressure from 600 to 800 Pa;

- heavy pipes SN8 with wall thickness from 3.2 to 15.3 mm, varying from diameter, transfer pressure from 800 to 1000 Pa.

A sewer pipeline capable of withstanding pressure up to 1.6 MPa is made of unplasticized PVC with a wall thickness of 0.5 to 1.9 cm.It is used for laying to a greater depth, under automobile highways, in pressure sewer systems.

Sewer pipes are divided depending on the installation site. The external and internal waste system is allocated. For arrangement of the internal sewerage use pipes of gray color. Standard diameter sizes are 32, 40, 50, 75, 110 and 160 mm. Wall thickness is not designed for high load, ranging from 1 to 3.2 mm. The length can be 0.3, 0.5, 1, 1.5, 2 and 3 meters.

Pipes for external drain differ in orange. Depending on the amount of wastewater, diameters are 110, 125, 160, 200, 250, 300, 400 and 500 mm. The size of the wall starts from 3 mm, the length varies from 1.2 to 3 m. For arranging urban sewer systems, a diameter of 200 mm is used.

Depending on the pressure to which the walls of the pipeline are subjected, a pressure and non-pressure sewer system is emitted. For the internal gravity sewer take the pipe with a wall thickness of 1.8 to 3 mm. For the outdoor pipeline with non-pressure drain, products with a wall size of 3.2 mm with a diameter of 11 cm to 1.2 cm with an external diameter of 50 cm are produced.

Pressure sewer system with pumping equipment requires high strength characteristics.Plastic pressure pipes are made of unplasticized PVC with greater thickness. The table shows the possible parameters of the wall, depending on the test pressure from 800 Pa to 1.6 MPa.

Diameter, mm | Wall thickness mm |

90 | 2,2–6,6 |

110 | 2,7–8,6 |

160 | 4,0–9,5 |

225 | 5,5–13,4 |

315 | 7,7–18,7 |

400 | 9,8–23,7 |

500 | 12,3–23,9 |

In addition to the smooth-wall PVC pipeline, corrugated pipe is produced. It is characterized by increased rigidity and different diameters. Corrugated gray color of small diameter, is used to drain waste from the washing, drying, dishwasher. Two-layer corrugated tubular structures of large diameter from 11 to 120 cm are used for laying to a depth of 15 m with high mechanical stress. The table represents the size of the production of corrugated pipes.

Outer diameter, mm | Internal diameter, mm | Step of a ledge corrugations, mm |

110 | 91 | 12,6 |

160 | 139 | 12,6 |

200 | 176 | 16,5 |

250 | 216 | 37 |

315 | 271 | 42 |

400 | 343 | 49 |

500 | 427 | 58 |

630 | 535 | 75 |

800 | 678 | 89 |

1000 | 851 | 98 |

1200 | 1030 | 110 |

The inner side of the corrugated pipe is made with a smooth wall to prevent the accumulation of solid particles, and the outer surface is embossed. They are used for arranging sewage systems in high-rise housing construction, industrial production, social and public facilities.

How to choose?

When selecting the optimal size of PVC sewer pipes, the main parameter is calculated - the estimated volume of wastewater that passes through the pipeline. In a private household, the amount of liquid drained depends on the number of people living. The greater the drainage points located in the house, the wider the receiving drain pipe. External sewage cannot be less than 11 cm in diameter. For internal wiring in an apartment, it is sufficient to select sewage pipes of small diameter up to 7.5 cm. When draining sewage into a riser, the size of the circle should not be less than the diameter of the general highway. For buildings with five floors and below, this figure is 11 cm; if there are more floors, then the diameter reaches 16–20 cm.

For the selection of the optimal size of pipes at various points of the drain are guided by common sense. You should not install a bulky sewer network with high capacity in low-rise buildings and apartments. Efficiency will increase slightly, and the cost and area of accommodation will increase significantly.

Sewage pipes are selected according to the following criteria:

- by diameter;

- on wall thickness;

- along the length of the free end.

The size of the internal section or diameter determines the drainage load in the sewer system. Each point of sewage discharge involves the use of a diameter of up to 50 mm. The drain hole under the toilet provides a diameter of not less than 10 cm, since solid particles go into the drain. In a private house, a pipe with a diameter of 110–200 mm will be suitable for arranging external sewage. For sewers running from a multi-storey building, the cross-sectional diameter should be more than 20 cm. The size of the outlet to the sewer well in the yard area can be 30–50 cm.

The wall thickness determines the strength class of the structure. The thickness should be selected according to the expected load on the pipeline. Light pipes with walls of 1.2–2.2 mm are suitable for installation in systems with gravity drain with a minimum load in the internal sewage system. Typically, the diameter of such pipes does not exceed 11 cm. They can be installed for removal of sewage from the kitchen and bathroom in apartments and private houses. Pipes should be freely available or cover the box.

The pipes with SN4 strength class are the most common, used for internal and external sewage.The minimum diameter of the pipe is 5 cm with a wall of 2.6 mm. For a diameter of 11 cm, the thickness is 3.2 mm. Pipes of medium severity are installed for the common house riser and lead to the external drain. Such pipes are used in the external gravity sewer in private and multi-family construction.

Heavy-duty pipes of class SN8 and higher are used for pressure sewage systems. In order to accurately determine the wall thickness, you need to be familiar with the power of the pump and how much pressure it exerts on the system. The minimum wall thickness with a diameter of 9 cm is 3 mm, the maximum - 6.6 mm.

The selection of the length of the pipe depends on the length of the pipeline in different areas. The smallest section for domestic sewage is 30 cm. The length can be easily changed independently, depending on the configuration of the pipeline. To get a smooth cut of the desired length, from the tools enough to use a hacksaw. For external sewage with straight sections, pipes with a length of 1.5 to 3 m are often used. The smaller the connecting elements in the installation segment, the stronger and tougher the pipeline structure.

When choosing the size of sewer pipes can be guided by sanitary norms, which indicate the permissible diameter for various drains:

- Kitchen sink - 32-50 mm.

- Drain from the bathroom from each point - 50 mm.

- Drain from washing equipment - 25 mm.

- The supply of pipes to the riser is 50–75 mm.

- Fecal flow - 110 mm.

- Central strut - 110–160 mm.

- Output to the outer drain - 110–160 mm.

- External drain with drainage from the bath - 160–200 mm.

- With the withdrawal from the pool - 20-30 cm.

- City sewer communications - 30–50 cm.

Standards are advisory in nature and simplify the calculation of the size of the sewer pipeline.

Tips

To create a sewage system, PVC pipes are widely used due to ease of installation and operational characteristics. You can assemble the sewer system from modules of different sizes. The size range includes fittings for the transition to a different diameter of pipes (gearboxes), splitters and angle elbows. The interchangeability of pipe elements allows for repair work in a short time.

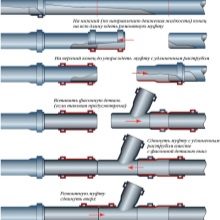

Unlike other plastic analogs, PVC products have a convenient assembly mechanism. All components and fittings in the pipeline are bell-fitting with a sealing ring. Additionally, you can coat with glue or sealant for strength.If it is necessary to connect two pieces of pipe, a coupling equipped with rubber seals is used. All adapters for sanitary outlets from the sink, sink, shower and bathtub are equipped with a bell groove.

In addition to the socket connection, an adhesive splicing method is used. Pipes differ in the form of the end and the sizes of walls. When selecting pipe products of a certain size, all fittings should be of similar diameter. This will help to achieve tightness in the pipeline.

At installation of sewer pipes it is necessary to observe a tilt angle for self-flowing system of discharge. If the pipes are 32–50 mm in diameter, then the optimal slope will be 0.03 degrees or 3 cm per linear meter. The circumference up to 110 mm implies a slope of 0.02 degrees or 2 cm. A diameter from 150 to 200 mm should be laid at an angle of 0.008 degrees, corresponding to less than 1 cm.

In the next video you will find the installation of plastic sewer pipes.