The use of plastic pipes in the ventilation system: what is good and how to mount?

The ventilation system serves as a modern assistant in creating a favorable atmosphere in the room due to air processing. Not only maintaining the comfort and coziness in the house, but also the health of all its inhabitants depends on its work. Especially the problem is relevant in the summer, when the inlet and outlet openings have a minimum difference in pressure, in which case the air begins to move in the opposite direction.

Concept and features

The job of the ventilation system is to process the air, replacing it with fresh air. A special role in efficiency is played by the selection of the material from which the pipe is made.The choice depends on the operating conditions of the system. Currently, the usual zinc-plated competition is made up of plastic pipes.

Such constructions, mainly installed in the kitchen during the installation of the hood, can overcome odors, water vapor and fatty inclusions. Devices are often hidden above the lockers, easy to assemble and maintain, are a basic element in the processing of air. The equipment is characterized by high performance and affordable price, and the lightness of the material provides a convenient installation.

Where is used?

Installation of plastic ventilation pipes is possible in any domestic premises, but especially in renewal of air need places with high levels of humidity and an unpleasant smell. For example, in the bath, ventilation will prevent the rapid deterioration of materials that lose their resistance under the influence of moisture and high temperatures, and prevent the growth of carbon monoxide and carbon dioxide. In the garage, the task of installation is to remove car exhaust and fumes, dry the body, blow out the inspection pit. In a chicken coop or other premises for livestock, the system ensures the elimination of harmful ammonia fumes.

The same problems are solved by ventilation in a private house. The air is inhabited by many bacteria and viruses, the number of which increases after suffering diseases of the inhabitants of the house. Airing windows can not cope with invisible pests. This issue will solve only the arrangement of the system of channels for the outflow and flow of air.

In the absence of such an installation, the materials from which the building is made suffer. Due to the accumulation of moisture in the walls of a private house, the appearance of fungus and mold, the formation of cracks is possible.

What are the?

In the production of plastic ventilation pipes, materials such as polyethylene, polypropylene, polyvinyl chloride, and fluoroplastic are used. Additional substances may be added for dyeing or product resistance to different temperatures and chemical agents.

Polyethylene

Constructions made of polyethylene are used by owners of cottages, country buildings. Polyethylene pipes are installed inside and outside the premises. Among the advantages of ventilation pipes made of polyethylene are the following:

- maintain temperature drops from -45 to +75 degrees;

- make it easy to lay connecting holes;

- Available with ultraviolet and anti-static coating.

Polypropylene

Polypropylene ventilation pipes are chosen by beginners or those who have a limited budget. In Europe, such designs are outdated, however, in Russia are still popular due to the following advantages:

- availability;

- easy installation;

- high resistance to aggressive chemicals;

- lack of hygroscopicity.

Nevertheless, it was not without its minuses - the material is not fire-resistant, durable, does not tolerate negative temperatures.

Polyvinyl chloride

This material is the most common option. It is used by tenants of apartments and small cottages. Users of PVC pipes celebrate such advantages as:

- ease of installation and use;

- material availability;

- tightness;

- the presence of ultraviolet radiation that protects against destruction.

However, over time, PVC pipes crack, and at temperatures above +120 degrees chlorine is released.

PTFE

Fluoroplastic ventilation pipes are set to supply and exhaust air mode. Among the advantages worth noting the following:

- resistance to vapors, acid-base solutions;

- mechanical strength;

- high temperature range from -40 to +140 degrees.

Due to the above properties, the structures are used for the inflow and outflow of aggressive air masses.

Advantages and disadvantages

Ventilation pipes perform the most important task in the operation of all equipment - they serve as a structure for the discharge of harmful impurities and excessive air humidity. For arranging the exhaust system in the domestic environment suitable pipes from a variety of materials, but plastic designs are particularly popular these days, which is due to a number of advantages, namely:

- small weight that facilitates installation and transportation;

- affordable price;

- the possibility of processing antistatic, after which the surface will not attract dust;

- easy installation of the exhaust pipe in hard to reach places;

- material safety for humans and the environment;

- compliance with sanitary and hygienic standards;

- corrosion resistance, durability;

- tightness due to the absence of seams;

- quiet operation compared to aluminum ducts;

- the ability to hide details to maintain the aesthetic appearance of the room.

Despite the widespread use of plastic devices and their advantages, with the purchase should be prepared for the minuses. The main one is the lack of resistance to fire, due to which use is limited by living conditions.

In industrial premises, a plastic installation may not be accepted by the relevant services when checking fire safety.

Parameters and elements

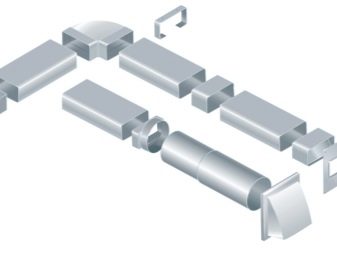

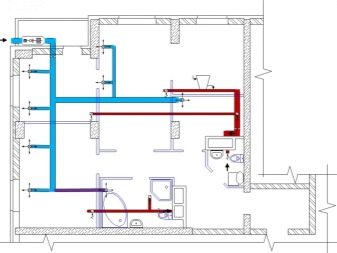

Depending on the shape of the section, there are rectangular and round types of plastic vent pipes.

Round

Round ducts are well suited for long routes of the ventilation system. In the shops you can pick up the diameters of 100, 125 and 150 mm. Such structures are usually used in everyday life - in the kitchen hood, bathroom, pantry. Advantages are resistance to acidic and alkaline vapor, smoothness, lack of resistance to air flow and noise. Usually in round ducts installed system for air flow.

The parts are assembled according to the type of designer, it is necessary to choose the right elements and insert them into each other.

Rectangular

Plastic boxes of rectangular cross-section are often used in places where they are easy to hide behind a suspended ceiling during installation. Typical dimensions are 60x120 and 60x204 mm. Among the advantages of rectangular ducts, it is worth noting the aesthetic appearance, ease of installation, space saving. Due to the smooth inner surface in the flat and rectangular channels does not create additional noise.

Rectangular ventilation pipes allow better installation of the hood, as opposed to round ducts, they are invisible above the cabinets. However, the cost of the rectangular elements of the system is 20–30% higher and the productivity is lower, so most of the owners still prefer to install pipes with a circular cross section in the kitchen.

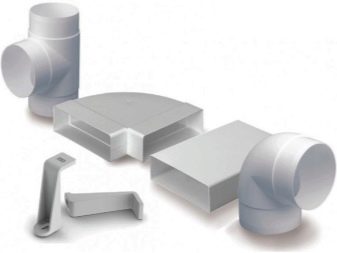

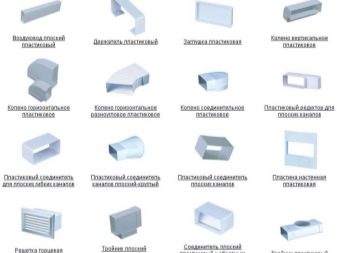

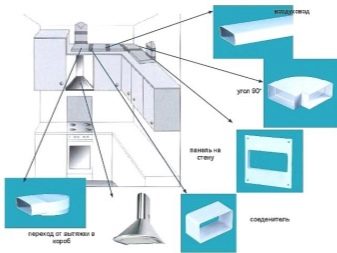

Other items

The fittings include connecting and horizontal knees, plugs, holders, grids, gearboxes, straight connectors, plates, tees - they are now easy to find in stores or order online. The main elements of the ventilation systems include the following:

- fitting for various purposes are used to install air ducts, namely for tight connection of parts into a single system.Thanks to these elements, a smooth transition of pipes of different diameters is possible, creating an angle of 90 degrees, connecting the air duct with an exhaust hood and a ventilation hole;

- adapter is the most important element of the hood. It is used in cases when it is necessary to connect pipes of different cross-section or air ducts of various sizes;

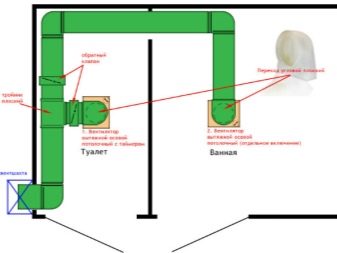

- check valve - This is another important detail that allows you to avoid the effect of reverse thrust and the return of exhaust air to the room. The dynamic valve blade opens only in the direction of air flow into the ventilation shaft.

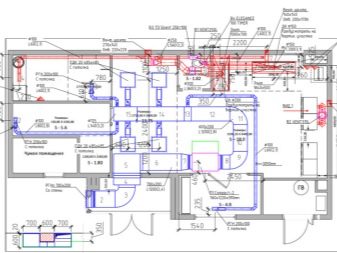

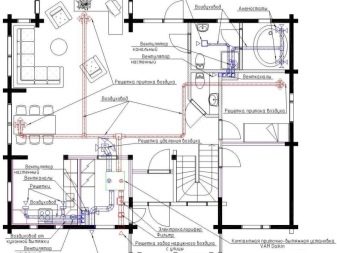

Design and calculation

Installation of the ventilation system must begin with the design. At this stage, you should calculate the performance of all elements, otherwise you may encounter the problem of insufficient air circulation or strong noise during operation.

The calculation of the internal and external climate is made in accordance with regulatory enactments. It is necessary to determine the required heat transfer and the amount of air consumed per person per hour. Already on the basis of these data, the type of ventilation is selected: general or local, supply and exhaust or exhaust, natural, mechanical or mixed.

The calculation of air distribution is carried out in different ways: displacement or mixing, supply and removal of air from the bottom to the top, types of supply air jets, design of the number and types of air distributors. The correct calculation at the design stage will avoid the rapid destruction of components and costly repairs. Basically, in the kitchen it is customary to install supply and exhaust ventilation systems. One element draws in the exhaust air, the second part is responsible for the intake of fresh air.

When designing, it is necessary to draw up a graphical scheme and indicate such basic parameters as:

- length of pipes for distributing air channels;

- number of air ducts, their localization;

- placement of air intakes, grids and other equipment;

- description of the materials used.

It is better to entrust the design and design of the hood to a professional who knows the nuances of installing supply and exhaust ventilation and who can accurately calculate the dimensions of the elements used. From this directly depends on the efficiency of the entire system.

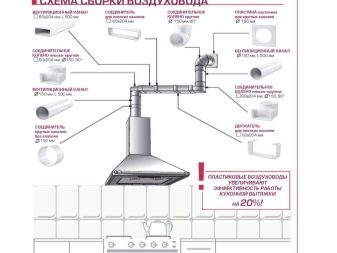

Installation

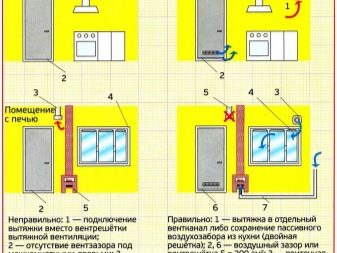

Installation of ventilation is to start after proper calculations and the purchase of necessary materials.Work should be carried out at the stage of rough repair, that is, at the end of plaster and putty walls. For high-quality installation, you should observe the following conditions:

- do not install the hood directly on the outlet for ventilation;

- use a vent with a check valve;

- do not use pipes with a small cross section;

- do not block the areas with fan blades;

- install the equipment at a height of more than 1.7 meters.

If the above actions are not observed, the system for supplying the dwelling with fresh air will be disrupted.

Installation of plastic ventilation pipes with their own hands is not particularly difficult and resembles the assembly of the children's designer. The work will require the following tools:

- flat duct for exhaust ventilation;

- horizontal and connecting knee;

- wall plate;

- round reducer with an adapter;

- plastic hacksaw;

- sandpaper;

- glue, sealant;

- marking tool.

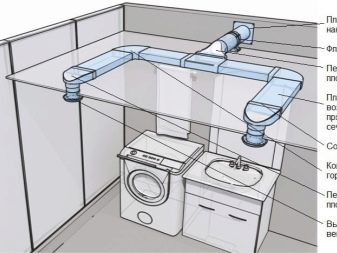

First of all, you need to arrange the stove closer to the outlet, otherwise the duct will have to pull through the entire room. Installation of the ventilation system is as follows:

- during the preparation of structures, it is necessary to cut off the desired length of the workpiece and clean the edges;

- on opposite sides of the kitchen, holes must be made to install devices;

- it is necessary to attach the duct to the wall and ceiling with special clamps using brackets or studs. It is not recommended to use screws as an attachment.

- it is necessary to equip the exhaust device with a check valve and a suction fan;

- connect the exhaust pipe to the exhaust device;

- it is necessary to install a filter, an air heater, an air conditioner, a recuperator to the suction structure;

- it is necessary to fasten the duct with the air intake system;

- to mount additional elements, for example, noise and heat insulation.

When installing the ventilation system it is worth knowing that the presence of turns reduces the efficiency. Each corner reduces productivity by 10%. The shorter the total length of the pipes, the more efficient the exhaust will work. The same 10% of the work of an extra meter is lost when the length of the pipes is more than 3 meters. Installing the hood is a convenient and uncomplicated process that is carried out without unnecessary noise and debris, the work is done as soon as possible.

How to hide and check: tips

Plastic vent pipes are usually not so easy to disguise, therefore it is recommended to foresee their location when installing wall cabinets. A great option is the hood and pipes built directly into the frame of the kitchen unit. Some masters in the installation of suspended ceilings also offer their services in the design and arrangement of ventilation. Well in this case, fit a multi-level ceiling. If you place the lower level around the perimeter, then all communications will be hidden.

The most budget way to hide the duct is his painting. Usually, the color is chosen in such a way that the equipment is in harmony with the main palette of the interior and does not catch the eye.

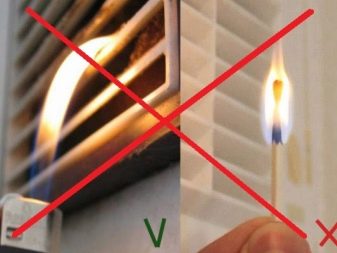

To check the performance of installed pipes, you can use thin paper, even toilet paper will do. To do this, slightly open the window and attach a piece of paper to the tightening grid. If the paper assumes a vertical position, then we can assume that the ventilation is mounted qualitatively. If the sheet does not hold and falls, the system does not work.The operation of the technology can be checked using a special instrument - an anemometer. The device shows the speed of air in the mine. Normal air circulation in the kitchen should be 60 m³ / h, subject to the availability of an electric stove.

When checking the ventilation in the kitchen and in the bathroom, you can use the same methods. Normal air circulation in the specified rooms should be at least 25 m³ / h. If the anemometer determines lower performance and the hood is in good condition, it is recommended to increase the air flow, otherwise mold will form on the walls due to increased humidity, and unpleasant smells will spread throughout the apartment.

Use when checking with matches, cigarette lighter or candles is prohibited. This is an extremely unsafe method, the probability of gas leakage and its accumulation in the ventilation shaft is small, but it exists.

The main causes of ventilation failure can be identified as follows:

- errors at the design stage - in this case, you will have to reinstall the hood, taking into account the mandatory requirements for the air exchange system;

- blockage of the ventilation channel - to fix the problem, you can remove and clean the grill yourself or consult a specialist.

In order for the ventilation system to remain in good condition for many years, the following operating conditions should be observed:

- monitor the status of filters and change them in time;

- equip the hood at a height of 65 to 70 cm from the cooking surface;

- periodically check the motor for the presence of fat, if necessary, remove it;

- include appliances in advance of cooking;

- eliminate dirt on the body with a soft sponge with minimal use of household chemicals;

- arrange the socket for switching on so that the device wire does not overheat during operation of the plate.

A plastic pipe ventilation system is a convenient and affordable option that does not require special care, it has been serving for many years and yet has more advantages than disadvantages.

The installation technology will not seem complicated even to a novice master, but it is better to entrust the calculation of the required indicators and design to a specialist. Only then will the ventilation effectively maintain the microclimate in the room, protect the occupants of the apartment from inhaling the stale air and associated diseases, and protect the covering of the walls and ceilings of the premises from rapid wear.

For more details on the installation of plastic ventilation, see the following video.