Technical characteristics of PVC pipes for electrical wiring

PVC pipes are the optimal solution for the installation of electrical wiring, as their plastic enclosures can reliably protect the electrical cable from unwanted damage, and thereby prevent a fire from closing.

Advantages and disadvantages

For a long time, metal pipes were used to perform electrical work, performing a protective function, but as time shows, PVC products are much more suitable for this purpose.

PVC pipes for electrical installation have such advantages as:

- low level of flammability, able to prevent ignition;

- no corrosion;

- full protection of wires from deformation;

- the risk of electric shock is excluded even if the cable is damaged;

- no need for grounding and welding;

- there is the possibility of laying wires in any conditions, including at high humidity;

- material is lightweight;

- installation is simple;

- polyvinyl chloride is resistant to low temperatures;

- when installed, the material bends easily due to plasticity;

- Increased strength and elasticity of the product provides for a long service life.

At the same time PVC pipes have a lower cost than a similar material made of steel or copper. To work with these universal products do not require special skills, as well as additional protection of electrical wires. Despite the fact that these products are the most fire-resistant and optimally suited for electrical work, they have their drawbacks. Compared to low pressure polyethylene products, they are less resistant to UV light, and the lightest due to their small thickness, the pipes are quite susceptible to mechanical loads.

In this regard, those and others are more often used for indoor installation or in places where there is no strong pressure on them.

Types of material

PVC pipes are available in several versions.It is worth noting that soft and hard tubes are used for walls of different materials, in addition, they are used for screed floors.

Smooth

Smooth (straight) materials are ordinary hollow cylinders of slightly combustible polymers, which are used in open areas of the walls. Thick-walled products are the most durable, their use mainly relates to industrial premises where the risk of mechanical damage to the cable is high. The most sought-after product of this type is the D20 smooth electrical pipe made of polyamide, which serves for indoor and outdoor installation inside buildings. This is a white or gray tube with a diameter of 20 mm, halogen free, moisture resistant with high elasticity and does not propagate burning. Installation and operation of this product can be carried out at temperatures from -15 to +90 degrees.

The flexible material has a large bending radius (160 mm), high impact and tensile strength.

Corrugated

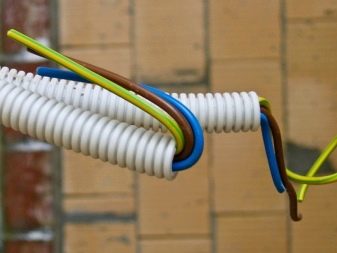

A special place is occupied by corrugated, flexible materials, which are convenient for connecting cables with uneven surfaces, as well as in hard-to-reach places.Such electrical pipes contain inside a special wire (broach) and are packed in coils of 15, 20, 25, 50, 100 m. The main purpose is the external laying of electrical wire. Based on the diameter of the material, it is possible to have entire bundles in the pipes of the wire, and thanks to such opportunities to install electrical networks of increased complexity. In this regard, it is worthwhile to consider in more detail the technical characteristics of these products.

Corrugated PVC pipe complies with GOST standards, like other PVC pipes used for electrical cables.

Such pipes have the following technical characteristics:

- guarantee a high degree of protection (GOST 14254);

- equipped with a special broach;

- thick-walled materials allow laying under the cement screed flooring;

- installation can be carried out at a temperature range from -50 to +50 degrees;

- The material is self-extinguishing.

Double-walled corrugated pipe inside has a smooth layer, the outer - corrugated. The material is not afraid of mechanical impact, high and low temperatures, vibration.Additional accessories in the form of a broach allow installation quickly and easily. The standard product is used for laying in floors and walls, ceilings, in residential premises and industrial workshops, in street conditions. Store products can be up to two years with the integrity of the package.

Reinforced PVC pipe is a spiral frame with soft polyvinyl chloride. It is a material with increased plasticity, which makes it possible to use it at high vibration, in places with significant bending of surfaces. Such pipes can be light and heavy with thick walls, with and without broach.

However, all products are water resistant and wear resistant. The diameter of these products can vary from 16 to 63 mm.

NPVH

Pipes for electrical wiring from unplasticized polyvinyl chloride are smooth products that can be used for both hidden and external cable wiring.

These products are classified according to criteria such as:

- the type is normal - “H” and reinforced “U”, when laying in concrete foundations is required;

- in appearance - with or without a socket;

- according to the size of the wall thickness.

Any products have a length of 3 to 6 m according to GOST. Installation of products with sockets is carried out by connecting straight ends to the sockets. When performing electrical work, it is recommended that gaps be filled with a special adhesive base based on PVC resin. PVC-U pipes are made of non-combustible polymeric material, have low weight. The lifetime of the product is 50 years.

Wiring installation

For conducting electrical wiring using PVC pipes You will need additional components designed for each type and model, namely:

- connection box with junction box;

- holder with a latch for fastening pipes to walls;

- fastener with clamp;

- corrugated coupling;

- transparent coupling;

- polyethylene staples;

- knee (square) for connecting at a right angle;

- tee for T-shaped connections;

- special coupling for wet rooms and the street.

And also need the presence of hardware such as clips, turns, dowel-tie, crosses. In order to correctly and accurately position the power grid, you will need a construction level when working.

Installation is carried out as follows:

- First of all, markup should be made for placement of pipes with wires. To prevent the cable from heating, it is necessary to protect them from any heating elements by a distance of 0.5 meters;

- every 10–15 cm the pipes must be fastened, therefore it is necessary to think in advance which fasteners will be used;

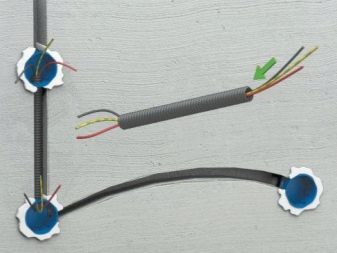

- further, the junction boxes (PVC components) are mounted and the location of the clips and fixing clamps are marked up;

- it must be ensured that the voltage does not exceed 15,000 V;

- after that the cable is leveled, inside the PVC pipe must be clean;

- fastenings are placed on the marked areas, and the tubes are cut into segments of the required size;

- tubes are placed in clips with fitting fasteners to their diameter;

- the electric wire is pulled through the tube elements with the help of a special broach, separate sections are interconnected, including bends, turns;

- cables can be carried out in several pieces directly into the junction box, and then connected to specific objects.

It is important to ensure that all connections are as reliable and tight as possible.

Installation Recommendations

It doesn’t matter if PVC is smooth or corrugated pipe, it is necessary to consider the following nuances when installing the wiring:

- if carrying the cable involves pulling from wall to floor, it is better to use corrugated connectors;

- It is always better to connect two different points with the help of a whole length of polyvinyl chloride;

- should not be allowed to go broach inside the protective profile when biting it with a side cutter, in the future it will make you spend time getting it;

- some pipe models do not assume the presence of wire - in this case you can use nylon or metal broach;

- if the electrical wiring is mounted in a brick wall or in a floor, then the protective system is previously fixed with the help of metal brackets;

- before holding the cable, fasten it with PVC tape in several places;

- tubes cannot be broken, otherwise later it will be extremely difficult to pass wires through them;

- when a whole cable bundle is pulled through, the wire must be wrapped around it quite firmly - you can pull it off with pliers;

- care should be taken to ensure that individual wiring does not stick out in different directions, which will make pulling more difficult;

- in general, it is better to perform such work together, then they will be performed better and quickly.

PVC pipes are the optimal solution not only to protect the electrical cable, but in this way it is possible to prevent damage to telephone and television wires, as well as to protect various types of alarm.

In more detail about how to make installation of an electrical wiring in PVC pipes, the following video will tell.