PVC pipes: technical characteristics and application

PVC pipes are becoming more widespread. The scope of their use today is very large - from use in production to solving household tasks. Unlike the same metal analogs, plastic is more convenient to use, they are more durable and cheaper. And this is only a small part of their merits.

Design features

Polyvinyl chloride pipes (PVC) are a thermoplastic, which in a special way is given the desired shape and size. Thus, a pipe in cross section can be round or square, and have the shape of a rectangle. The diameters are also very different depending on the destination. The smooth surface inside the product prevents the deposition of residues of transferred substances on it, which is very important from the point of view of sanitation.

There are several types of polyvinyl chloride:

- PVC;

- NPVH;

- CPVH.

Each of them has its own characteristics. Ordinary polyvinyl chloride can withstand temperatures up to +40 degrees. Therefore, PVC water pipes are not used in hot water systems or heating. For such purposes, use CPVC products (from chlorinated polyvinyl chloride). They normally withstand temperatures of +95.

Also, this material is resistant to aggressive substances. In addition to water, oil, soap, various acids, oil, mercury and so on can flow through the CPVC pipes. This material is used in food production. For example, to transport milk or beer.

NPVH - non-plasticized PVC. The streams of this composition can withstand high pressure. If conventional PVC products are resistant to no more than ten bar, then the non-volatile PVC can withstand up to sixteen. Products from this kind of polyvinyl chloride is used for the device of sewage system and external water supply.

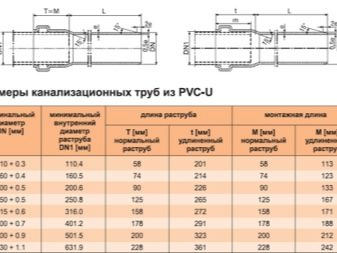

Of great importance for a particular use of PVC pipes has their size. Inside the house used pipes with a diameter of twenty-five to fifty millimeters.A device with a diameter of 110 millimeters may also be needed for the construction of a sewage system, and outside the house it is 200 or more.

Advantages and disadvantages

PVC pipe has a number of beneficial properties.

- It can be rigid or flexible, which allows it to be used in different areas. For example, for laying of external sewer networks, internal plumbing, various cables.

- It withstands severe mechanical stress. It can be used to isolate electrical wiring laid in monolithic walls and ceilings. When creating an outdoor sewage system, such pipes fall below the ground to a depth of nine meters.

- Unlike metal counterparts, such a product will not rust. Can serve at least fifty years.

- The temperature of the fluid transmitted through the PVC pipe practically does not fall during transportation.

- Water flowing through a PVC stream is completely safe to use.

- PVC pipe weighs little, which makes it easy to install a sewer or plumbing system.

- To create the necessary utility network does not require the use of expensive tools and complex fasteners.

- To create a home plumbing or sewage does not have to invite a specialist, which saves on installation.

Among the disadvantages of PVC pipes can be noted low resistance to negative temperatures. Damage is possible already at -15 degrees. Outside plumbing may even break when frost occurs. It is possible to avoid such a development of events by envisaging proper execution of thermal insulation.

Another unpleasant side of polyvinyl chloride is that during its processing harmful substances are released. It soothes that it is practically impossible to face this in everyday life - the corresponding reaction with the release of toxins in polyvinyl chloride begins only at +400 degrees C.

But it should also be borne in mind that when transporting PVC pipes they can not be put vertically. In the car, they must "go lying." It is impossible to drag such products with fiber, but only to carry them in order not to damage the material.

Classification by purpose

Plastic pipes are divided according to their purpose. They are pressure and non-pressure, related to such varieties of polyvinyl chloride, as PVC.

Pressureless designed for sewage, in which water flows by gravity. This may be the engineering system of a residential building, a quarter, a production center, or storm sewage.

Pressure pipes are used where water is supplied under pressure. To assemble such a system, you need to use adhesive joints.

PVC pipes are used in various areas of construction.

For plumbing

Such applications are usually found products of PVC one with a length of two, three or six meters. Traditionally, bell-shaped structures of gray color are used here. It is possible to lay such PVC products even at great depth in moving soils and in seismically active areas.

Sewer

For the device of the internal sewage system, gray products with a bell and a maximum length of three meters are also used. Wall thickness for gravity systems typically exceeds 1.8 millimeters.

Apply PVC pipes of orange and yellow colors to the external sewerage. They are designed for particularly harsh operating conditions. If such a pipe is to be placed at a depth of four meters, its wall thickness should be 3.9 millimeters.With a six-meter depth, you will need a product with a wall thickness of almost five millimeters, and with a eight-meter depth - from six millimeters.

These conditions are spelled out in GOSTs, and they are guided by them in drafting sewer systems.

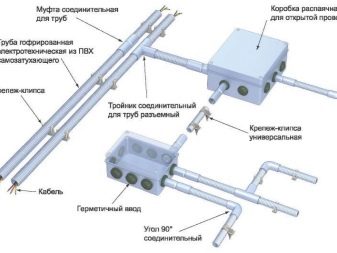

For cable

Since polyvinyl chloride does not pass the current, it is used when laying electrical cables. Tubes protect them from damage. If the wiring closes, PVC walls will not allow the fire to spread. Such a pipe is one hundred percent resistant to moisture. Over time, it does not lose its operational properties.

You can mount it at a temperature of from -5 degrees to +60. It is successfully operated in the range from -20 to +80 degrees.

For use as protection of cable networks are pipes with a diameter of 16 to 63 millimeters. For example, a 16-mm pipe may be suitable for electrical appliances, a 20-mm pipe - for switches or sockets, and so on.

To protect the cable and other networks are manufactured products with smooth walls and corrugated. Pipes with a smooth structure are three meters long, and corrugated products are delivered in bays of fifty meters.

Smooth pipes for cable are usually used in various institutions and enterprises, laying them under the ceiling, although they can be mounted in a hidden way.

Gofrotruba due to its device is the most durable. Unlike the usual smooth one, it’s not terrible to wall up in a concrete wall. It will successfully withstand the external load, keeping the cable intact.

Upsetting

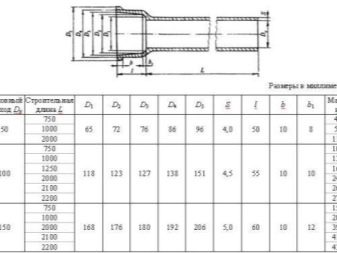

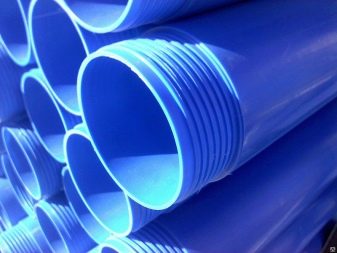

Such PVC pipes are used in the field of oil and gas production in drilling wells. These products are widely used in the arrangement of water wells in rural areas. They do not allow the soil to collapse and get into it from the high layers of the water, rather than from the depth at which the hole is pierced.

Another purpose of PVC pipes - use in the construction of wellsfrom which pumps lift water. Such casing pipes are installed to protect pumps from the effects of the natural environment and gradually replace metal products subject to corrosion. The size of the casing depends on the dimensions of the engineering structures themselves for pumping water. The diameter of the pump should be four millimeters smaller than the inside diameter of the casing.

Such PVC products can be distinguished by color - they are blue.The length of the segment can be from one to five meters (in increments of a meter).

Such pipes during installation of the casing are interconnected by means of threadprovided at the ends of the products. The well should be strictly vertical and even. If this is not the case, then in the process of pushing to the depth the pipe may burst. It is better to use PVC products for casing in the case when special equipment is used for drilling a well, which allows to make an even hole.

Compared to metal pipes, the use of polyvinyl chloride wells for the device has indisputable advantages due to the properties of PVC since the long service life of this material. Fifty years is much better than five to ten, which, under the conditions of a well, serve as ordinary steel pipes.

Although plastic casing has drawbacks. They can not be stored when exposed to direct sunlight, and doing the installation in the middle of winter, all work must be done with great care.

Profile

Profile pipes are widely used in the economy.Of them create a box to protect the metal pipelines on the main networks and individual sections. With their help, they develop underground channels for laying fiber-optic, telephone and electrical cables. Used to create plumbing and drainage communications, air ducts.

In addition, such materials are actively used as carcasses for greenhouses and support posts for fences. The profile pipe is even suitable for creating light furniture and other things that are necessary for the household.

For example, fences assembled from square-shaped pipes will be well bred. And also this material is very convenient when creating drinkers with a nipple system for animals and birds.

The standard length of such pipes is 4 and 5 meters. The cross section is different: 10 by 8, 6 by 6 and 4 by 6 centimeters.

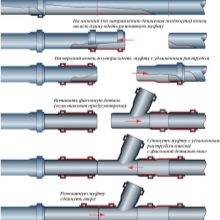

Connection methods

When creating a plumbing or sewer system, various methods of connecting PVC pipes are used. Can be applied to the closure of the socket using a rubber cuff. This is a part that ensures the tightness of the joint. In form, such elements are often cylindrical, sometimes resembling an ellipse. Have thick walls.For reliable fixing silicone is used.

You can also connect pipes by welding. This method of bonding is considered the most reliable. The pipes in this case must be cut very smoothly. The ends of them are heated to a certain temperature with a special welding machine, and then firmly connected. This approach is often used when laying underground pipelines.

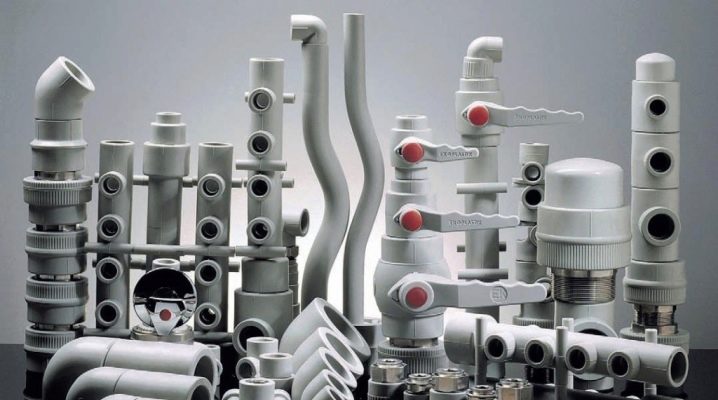

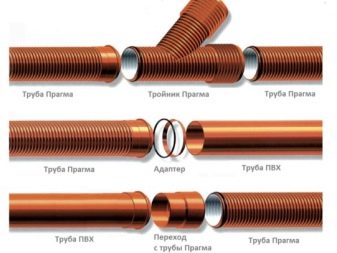

An excellent option to create a network of pipes is to use fittings. These are elements of various shapes and sizes that make it possible to join pipes in the most bizarre way. Such connecting parts are made of various materials, including PVC.

Among them are:

- adapters;

- couplings;

- fittings;

- tees;

- stubs

To create external and internal pipelines often use plastic fittings. External communications are mounted with elements from NPVH, as well as pipes from this variety of polyvinyl chloride, capable of withstanding great pressure of the transferred liquid. Because of this, you can use these fittings in the organization of pressure water systems.

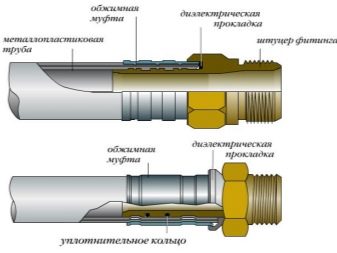

If metal pipes are attached to a PVC plumbing system, then connecting elements with brass inserts are used.

To ensure that the pipe joining through the fittings is reliable, the system elements are glued together. This method of joining is also called cold welding. Prior to this process, all components are checked for compatibility. The pipe should penetrate the fitting to less than two thirds of its depth. With trimmed to the desired size of the pipe carefully clean the chips, process the edge with emery paper. The surface at the stripping point is degreased.

Glue is applied to the inside of the joint element. Then the pipe is inserted into the hole and rotated a quarter of a turn so that the adhesive composition is evenly distributed around the circumference. Combined parts of the structure must be fixed manually. After half a minute the glue should grab. But for loyalty it is better to wait at least a minute. After completion of the procedure, the surplus of the adhesive composition remains to be removed with a napkin.

Another option for pipe fastening is to use a threaded fitting that applies to smooth pipes. The fitting is inserted into the pipe, and the connection is crimped with a special lock nut. The end of the pipe in this case should be completely flat.It should be cut perpendicular to the axis.

The disadvantage of this connection with all the ease of installation is that after some time the thread tension will weaken and the joint will “flow”.

To fasten pipes of the sewerage, use also collars. Parts of the system, in fact, are wrapped around with such fasteners. In addition to the most enveloping parts, the clamp is equipped with an anchor or dowel. Thanks to this, the pipe can be simply attached to the wall. Such devices for connecting pipes are metal and plastic.

A gasket is provided in the design of the clamp, which is installed between the pipe and the clamp of the connecting device. Laying absorbs noise and vibration from the movement of water in the watercourse.

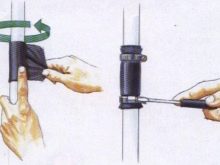

As for corrugated PVC-pipes, they are very convenient in operation - for quick tightening of the wire inside the pipe, it is created with a broach - with a metal wire, to which the cable is connected and pulled through it through a corrugation. Just connect the corrugated pipe is not as easy as other PVC products.

In this case it is impossible to use the fittings due to the corrugated surface, heat welding does not guarantee the reliability of the connection, since at low temperatures the power of the soldering iron may not be enough to melt the corrugation.

As a temporary connection, electricians wind the joints with electrical tape, but only the use of couplings ensures reliable fixation. This is a plastic element into which the ends of the corrugated tubes are inserted. Such couplings, like fittings, can be straight, angled, and have the shape of a tee. The only problem is that using them is expensive.

Pipeline installation

Using various methods of fixing the individual elements of the pipeline, you can mount a reliable sewage system or water supply system with your own hands.

First you need to decide on the procedure for the upcoming installation and the necessary set of tools. At this stage, a diagram of the future pipeline system is drawn up with the dimensions of the pipes, the number and methods of connections.

Measurements are made at the location of the structure, pipes of the desired size are cut. To do this, you can use a hacksaw for metal or a special cutter.

When installing sewage in the house, the installation of pipes starts from the riser and is carried out to each sanitary ware product.

The pipes in this case are simply connected. The end of one is inserted with a connecting element with a rubber gasket on the other. It is important that at the time of connection of the pipe is not twisted, and one entered the other until it stops. If the entry fails, a characteristic sewage odor may appear over time in the house.

To prevent possible trouble, the pipes in the joints must be thoroughly cleaned of dust and dirt. It will help simple reception when the end of the segment, like a rubber gasket, is treated with soapy water, which allows to ensure the reliability of the connection.

When the pipeline as a whole is assembled, it is the turn to connect the plumbing. On the bath and sink is better to install siphons. In their operation, debris can accumulate during operation, which, without the use of such additional “pipe bending”, would cause a blockage in the sewage system itself. In addition, the siphon is a kind of water tank that prevents harmful gases from entering the house from the sewer system.

Finally, make sure that after the installation of the pipeline all its connections are securely sealed. It is enough to pour water into a bathtub or a sink and see if the liquid is leaking from the hoses and pipes.

If it starts to drip somewhere, you will have to dismantle the pipeline in the problem area and re-connect the elements of the system. Inspection and installation work is repeated until the pipeline functions perfectly.

As for the sewage device outside the house, under its device you need to prepare the soil and make a pillow out of sand. Stacked pipes can be fastened with hose clamps. Pipes need to be laid so that they have a slope. Otherwise, the liquid will not be able to move through the sewage by gravity.

If the track is long, every thirty meters you need to create special wells, which will allow you to maintain the system in case of problems. If this is not done, then the repair will have to dig the entire pipeline.

If we talk about the installation of water supply, here we must take into account that the system will operate under pressure, so the reliability of the connection of the pipeline elements will ensure the use of a welding machine, the so-called ironing. Before using it, you should carefully study the instruction manual. Features of the device depends on the power of its heating element.

The work itself should be carried out in protective glasses and gloves.which are usually included with the welding machine. Otherwise, the risk of getting burned greatly increases.

In the process of installation using ironing, pipes and fittings are heated to a certain state, and then inserted into each other with strict adherence to technology. The heated parts of the pipe and fitting should “tightly grow together” in ten to fifteen seconds, which will ensure a reliable connection.

Service and Repair

Despite the fact that plastic pipes are smooth, which should prevent the appearance of plaque on the walls and blockages in the path of the passage of liquid, anything happens with the pipelines. This is especially true of sewage, in which people manage to pull the most inappropriate things ranging from diapers and women's pads and ending with cat litter.

Often, blockages occur in pipes of small diameter or in a system with a significant number of turns. The source of trouble is often in the kitchen, from where, due to the specifics of using this place in the house, the sewage system passes the remnants of food falling into the pipes after washing dishes, and fat is deposited on the walls of the pipes.

To clean the pipeline, you can use special chemicals. It is important to use such reagents that do not spoil the pipes themselves, as well as rubber products, which are used at the joints of the system.

But you also need to keep in mind that if the water, though bad, but leaves, the blockage in the pipe did not completely block the passage. This means that the chemical agent may not work. To achieve the normal operation of the sewage system, the pipe will have to be completely blocked and after that it will be necessary to fill in the necessary product for several hours.

If the blockage is not too serious, formed due to the large amount of fat deposits on the walls, then it will be easier to pass a significant amount of hot water through the system.

If simple methods do not help, it makes sense to try to clean the pipes mechanically. In this case, “plug” is eliminated with the help of a sanitary cable. While deciding on such a procedure, it must be borne in mind that it is necessary to act extremely carefully. With a large number of turns in the system, you can make a bad breakthrough and break the existing pipe connections.In addition, a coarse cable can leave scratches inside, which in future will “attract” new blockages.

It should always be borne in mind that mechanical impact on the PVC pipe can lead to its rupture. The only way out in this case is to replace the damaged product with a similar one. To embed a new piece, electrofusion couplings are used, as well as those that are mechanically attached. You can also use the welding method.

If a small “hole” has formed on the pipe, the size of which does not exceed five centimeters, the sewerage system will have to be dehydrated, pollution in the damaged area should be removed and the plug should be welded to the place of the break.

Under the influence of external factors, plastic sewer pipes are sometimes deformed. This is not always a problem, since the curvature may not interfere with the movement inside. Then it is better not to touch the pipe. It is enough to get rid of what caused the strain. Practice shows that in this case the pressure inside the pipe eventually returns it to its original position.

After some time from the start of operation of the sewer system, numerous leaks can begin in it.This development indicates that the installation was carried out illiterate, or used unsuitable pipes and fittings. In this case, it may be enough to eliminate leaks or need to replace some of the components.

From the video below you will learn how to make the foundation of PVC pipes.