How to warm the plumbing from plastic pipes under the ground?

Nowadays, polymer pipes (metal-plastic, polypropylene, polyethylene, PVC) are everywhere used for cold water supply of the house from wells or central water supply, as well as for wiring inside the house. The freezing of communications inside the apartment is rare. If the water supply system is laid underground, especially if the pipes are at a level above the depth of soil freezing, laid inside the wall, or passes through an underground space that is poorly protected from cold, then upon the onset of long-lasting severe frosts it may freeze.

Special features

Resumed the intensity of the movement of water and prevent the possibility of rupture of the aqueduct will help time taken measures focused on defrosting it.

In the process of implementation, the following points should be taken into account:

- when ice is heated in the pipeline, water begins to flow into the well or pit, so you need to take care of its collection and pumping out;

- heating the sewer (sewer) requires less effort when compared with running water, as a result of this work must begin with him;

- before defrosting the water supply, it is required to disconnect it from the central water supply.

It is necessary to start the elimination of the problem by finding the area to be heated, and it is necessary to ensure access to it. To do this, remove objects that hinder the passage, free the pipeline from isolation, and if the water supply is located underground, dig a trench.

Depending on the location of the freezing area, the method of external or internal heating is used. In any case, to recognize the effectiveness of the actions taken, the water valve must be left open.

What is required?

So, let's look at several ways to defrost these plastic pipes and define the tool that we need:

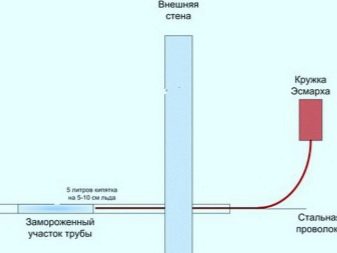

- Reception with the use of the Esmarkh medical group. Many years of fighting the defrosting of pipelines have improved the "tactical method" and significantly reduced the price and simplified the design of the device, which will help save the house from lack of water. For this method, we need: the Esmarch cup (popularly called enema, preferably 1–2 liters), a hose from a water level or its analogue of similar strength, hardened steel wire, and a tank for collecting water.

- The method of "boiler". This method of defrosting a water supply system is best suited for plastic or metal water pipes, in which water is available along the entire length of the pipe. To do this, we need: two 3–4 kW electric wires, a socket equipped with a fuse, a plug, and a steel strip. There are also other methods of defrosting, such as a gasoline blowtorch (for external areas), hot antifreeze, ultravolves, and the like, but these two methods are characterized by increased efficiency and simplicity.

We also note the existence of professional equipment for heating the frozen pipeline, which include hydrodynamic machines, autoclaves and steam generators.

Defrosting

Esmarch's irrigator

Consider the scheme of how to defrost the water supply using the Esmarch cup. This would require a hardened steel wire coil, a hydro level (water level), an Esmarch medical mug (enema) to make the simplest device. It is necessary to take a hydraulic level hose and wind it with wire or fix the wire with tape or tape. The end of the hose should protrude 1 cm forward. The other end must be connected to the outlet nozzle of the cup and proceed to pushing the structure in the water pipe before reaching the point of ice accumulation.

After that, hot water is poured into the Esmarkh mug and the tap is opened. As the ice plug melts, the tube must be pushed further. At the junction of the pipes, it is necessary to install a suitable container to collect the flowing water. This is a fairly effective defrosting method, but time-consuming.

Technology with a "soldier kettle"

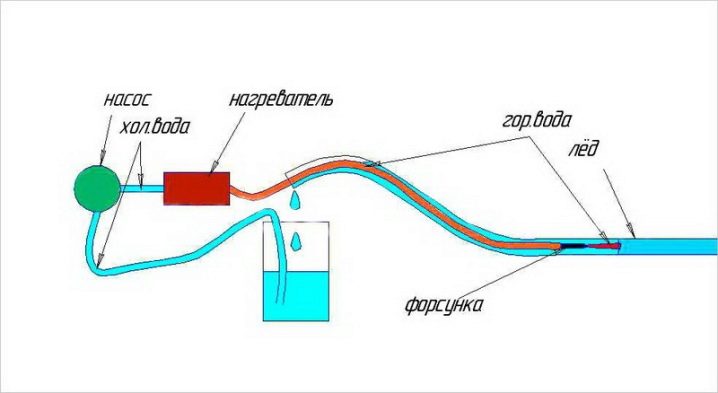

The easiest way to defrost a plastic water line is to use a two-core copper electric wire with a cross section of 2.5 mm. The principle of its operation resembles the principle of operation of an ordinary boiler. Water, in whose structure there are salts, is a weak electrolyte. And in order to carry out its heating, it is only necessary to lower two electrodes into it, and then apply electrical voltage to them. It is simple to make this device, for this purpose a two-core copper electric cable is necessary, with a cross-section of each wire not less than 2.5 mm We clean one end of the cable from the outer shell by 10–15 cm, one wire is bent in the opposite direction, the second wire is cleaned of isolation and tightly fastened to it with the first 3-4 turns to the cable, we remove the insulation from the end of the second wire and wind the cable.

The distance between the turns of the first and second wires should be about 3-4 cm. In fact, the design resembles a makeshift reboiler of razor blades, and here it is important not to allow direct contact between the two bare wires. Like its blade prototype, the “soldier's boiler” quickly heats the water, and due to its compactness and flexibility of the cable, it passes freely to the ice plug, even along the bends of the pipeline.It is desirable to power this device only through a 25 A circuit breaker.

Before use, test the device in a jar of water, just do not push your fingers into it, when the "boiler" is working, it may strike with current. You will notice the bubbles coming from the contacts and you will hear a buzzing sound. Place the finished device into the system and connect it to the power grid. After a certain time interval, the pipe will warm up and simply push the ice block. As this happens, the boiler needs to be turned off and the pipeline shut off. After cleaning and reconnection, the plumbing will work like a clock. For blowing melt water in addition, you can use a compressor.

Some more methods how to defrost a pipe from plastic

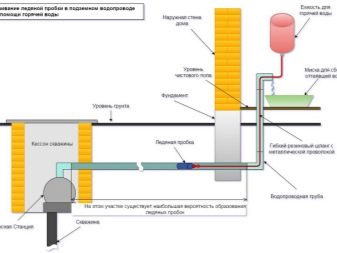

To defrost water supply there is also special equipment. This refers to steam generators, autoclaves and hydrodynamic devices. It is not necessary to buy them, you can take the required machine in a specialized service. Defrosting with this equipment is carried out as follows: Steam generator. It is necessary to place the hose of the apparatus inside the pipeline and supply steam under pressure.Due to the fact that the temperature of the medium is much higher than the boiling point of water, the defrosting procedure will be carried out extremely quickly, and will not cause plastic damage.

Autoclave (or double boiler). It also uses steam, but the principle of operation is slightly different. First, the water in the tank is heated until it turns to steam. Then a hose is pushed into the water pipe (before the ice jam), the second end of which is connected to the autoclave. As the ice is defrosted, the hose must be pushed through the pipeline until the water flows in the direction you want.

Hydrodynamic machine. This device destroys the ice plug, not by temperature, but by the pressure of a high-pressure fluid. As a result, ice can be discharged effectively and in minutes.

After defrosting the pipeline, make sure that the frozen water does not break the pipes.To do this, dig control holes above the laid pipeline, drain some water, then turn off all the taps and wait 2 hours - if there is a breakthrough, water will appear in the holes. Of course, winter is not the optimal time to replace or repair pipes,but the affected area will still have to be replaced.

Tips

Regardless of the chosen method of defrosting and the method of device pipes, A few tips to follow when thawing a water pipe:

- if you know the exact location of the ice block, you do not have to warm this section of the pipe directly from the middle;

- to ensure the removal of melt water is required to open a water tap;

- it is better to start the defrosting process from the consumer (supply valve) to the source of water intake (vertical riser).

How to prevent freezing

So that you do not have to repeat all the above procedures again and for those who are just planning to lay the water supply underground - some useful recommendations. The main rule - should worry about the correct installation of water supply. After all, it is better to dig it out and eliminate all the flaws than to eliminate traffic jams from frozen water every year. So, the first thing you need to take care of proper pipe laying. Ordinary plastic household pipes can not be compared with the trunk, which are constantly large volumes of water. Therefore, they must be buried below the level of soil freezing in your area.

In the central part of the Russian Federation, the pipe must be pulled at a depth of at least 150 cm (optimally 180–200 cm). Do not conduct the pipeline in the vicinity of reinforced concrete structures: supports, balls, foundations, grillages, because the thermal conductivity of concrete is much higher than the thermal conductivity of the soil, and soil freezing can be from the side of building structures. Where the water supply system passes under the concrete road, produce insulation (in particular, it is possible to lay plates of extruded polystyrene foam at a depth of 80–100 cm). Roads are usually cleaned of snow and in this place the soil will freeze to a considerable depth than on other sections of the road.

Keep in mind that water freezes in water pipes with a small diameter. Consequently, in the construction of an autonomous water supply, it is desirable to use pipes that have a diameter of 50 mm and above.

It is also necessary to worry about the warming.

You can organize thermal insulation under the ground in the following ways:

- The pipeline can be wrapped in basalt and fastened with tape. From above, as a material that plays the role of thermal insulation should lay bedding roofing material.

- You can also use ordinary foam with cut-to-butt ends. Wrap it with adhesive tape with glued moisture resistant glue.

- The most reliable, but at the same time, the most expensive method of insulating the pipeline is winding with a heating cable; at present, the industry produces self-regulating options that are connected only when necessary. If a similar method of insulation is used in a suburban private house, where no one lives permanently, the depth of the ditch under the pipe should be at least two meters. When the house is constantly living, enough holes and half a meter. It must be said that the heating cable is best practiced in areas with a small pipeline. Then the amount that will have to be paid for the installation of the cable will be significantly less than pulling it through a large area, besides, the amount of electricity used will not exceed 20 watts.

- The pipe at the points of passage through the walls must also be insulated with mineral wool, glass wool, can be placed in sleeves or simply zapenit so that there is no direct contact of the pipe with the building.

What not to do?

It is not necessary to use rags, paper and sawdust as a winding even for short-term insulation. When changing the temperature, these materials easily absorb moisture from the atmosphere, preventing the formed condensate from evaporating. Despite the extensive choice of effective methods and equipment for the elimination of ice traffic jams in the pipes, it is best to avoid such problems. Since, heating when defrosting pipes is a rather problematic procedure, which is hampered by the complexity of working in the cold. Observing simple recommendations, you can prevent the water supply from freezing, thereby increasing its service life.

For information on how to defrost a water pipe with your own hands, see the following video.