Features of the choice and use of glue for PVC pipes

Metal pipes used in the heating system, sewage systems, as well as those used for hot and cold water supply, have a rather limited service life. Pipes made of metal are highly susceptible to corrosion and today are practically not used when installing the above systems.

Special features

Quite often, the assembly and installation of pipes made of polymeric materials is performed by methods of diffusion welding or, to put it another way, by soldering pipes. In the case of using the composition for hot glue, the adhesive will need to be preheated. Also, this method involves the use of a special soldering apparatus, which will provide the most tight connection.

It is important to know that heating should be carried out at a temperature of at least 260 ° C, while this process will require fairly high skill, therefore, it is better to entrust the execution of such work to professionals.

Composition for plastic pipes, the so-called cold welding, every day is becoming increasingly popular among ordinary buyers.

The undeniable advantages of adhesive bonding:

- the risk of leakage is practically reduced to zero due to the fact that the details are connected at the molecular level;

- bonding is one of the cheapest ways to connect pipes, which will not increase the cost of repairs;

- the use of glue does not require any special skills, and such a process can be performed independently;

- using glue, it is possible to mount both polyethylene, and polypropylene, and also metalplastic pipes.

The principle of interaction of all adhesive compositions and polymer pipes is approximately the same: glue compositions partially dissolve the PVC material, firmly binding the particles, as special additives are included in the glue composition, which make it possible to improve adhesion. At the moment of gluing, the solvent evaporates, an intertwining of the molecular chains of the polymer occurs, and at the exit a hardening compound is obtained, gaining strength with time.

The only and, perhaps, one of the most significant drawbacks of using glue for PVC pipes is that it is designed for cold water supply systems, because under prolonged exposure to high temperatures, the joints can quickly lose their high strength properties.

Kinds

An important point when using the composition is that it is necessary to pick up the glue that will be able to provide absolute tightness of all necessary connections.

In this regard, the choice of glue is based on the properties of the materials to be glued. For example, a compound suitable for a polypropylene pipe will be significantly worse to glue PVC pipes together, and, accordingly, its composition is also necessary for polyethylene pipes.

On the market you can find many varieties of glue with various modifications of adhesives.

Single-component compositions, as a rule, are already ready for use, do not require additional procedures for preparing the work from the contractor, there is no need for mixing. Such compositions are packaged in plastic or metal containers. The composition of the adhesive base includes special solvents, allowing to form a fairly durable joint.But at the same time in one-component materials there are no specialized additives, which allows not to lengthen the time of chemical reactions that may affect the strength of the compounds.

Two-component adhesives have a slightly more complex chemical composition. Such varieties include additives that improve adhesion, reduce the time of the gluing process. They make it possible to obtain more stable bonds of polymers at the atomic level. The quality of the connection is better - the characteristic of such a junction allows you to approach in its properties to a solid pipe.

In the process of selecting glue should pay attention to the characteristics of the composition of the adhesive and its method of use. For the method of cold welding, both universal and special glue compositions are used.

The glue used for joining joints by the method of cold welding is divided into the following types:

- composition that does not fill the gaps - it is used in cases when the gap between the fitting and the pipe is less than 0.1 mm;

- the composition that fills the gaps - it is usually used when the gap is up to 0.8 mm.

The gap, which has a size of up to 0.1 mm, is found in cases when the internal water supply system is being installed, since fittings of small diameter are used for such works: up to 40 mm.

The gap, having a size of up to 0.8 mm, occurs when sewage systems are being installed, as well as when installing external plumbing, since the sockets in them are joined to products of large diameters.

How to choose?

Before using the glue, you should always carefully read the recommendations given by manufacturers. For example, most formulations are strictly forbidden to leave open for more than four minutes, otherwise they will quickly grab and their further use will become impossible.

If it was decided to buy a certain composition of glue, then you need to pay attention to how it needs to be prepared for work, since the two-component formulations described above must be mixed, carefully watching their consistency. If the adhesive components are not properly connected, there is a significant risk of change in the adhesive properties.

Before buying a substance, you should pay attention not only to the chemical composition and characteristics of the glue itself, but also to other important nuances.

- The place where the pipeline will be mounted.When gluing it is necessary to take into account the working conditions and the temperature of the liquid that will flow in the pipes. You should also pay attention to the overall contamination of the object and the ambient temperature.

- The pressure of the fluid that will affect the joint. The instructions for glue always indicate how much pressure the pipe can withstand when using glue. Accordingly, the higher the characteristic indicated in the instruction, the stronger the junction will be.

- The peculiarity of the load on the gluing place. Quite often, laid pipelines are subject to shear due to external mechanical stress or due to the resulting internal pressure. Such loads should be foreseen in advance and select the appropriate adhesive composition.

- Temperature mode of use of the finished product. For example, the types of glue that will perfectly connect pipes for a cold water supply system will be ineffective when using and installing a sewer system, since the temperature of the liquid flow is different.

- Toxicity. Any composition of glue, as a rule, includes quite a lot of volatile toxic substances, and if a person is prone to allergies,then it is better not to work with such toxins, or it will be necessary to provide special means of protection, or, alternatively, choose a different way of connecting the parts.

Today, bonding is often carried out with Tangit PVC-U quality adhesive with a capacity of 1 liter or 500 g.

Installation

Before you start using the adhesive, you must make sure that the room where the work will take place is sufficiently ventilated and the temperature is between 5-35 degrees Celsius.

Do not forget about the tools: when you need a marker (for marking), as well as various measuring devices. For a good pipe cut, well-sharpened pipe cutters, electric jigsaw or at least a handsaw are needed.

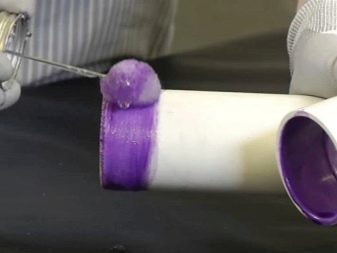

Before using the adhesive, it is necessary to clean the surface with high quality - for this you will need sandpaper, and in order to degrease the surface - solvent. In order to apply the glue, you need a dense brush of natural bristle or glue gun.

It is also necessary to prepare the surface. If contamination is present on the surface, the glue will only lie on top of the contamination, forming a film, which will lead to the formation of a poor-quality joint and the appearance of leaks.

Bonding technology

Initially it is necessary to mark the pipes. For this, a detailed gasket design must be prepared. On it will be measured tubes and markings for cutting.

The second stage is the cutting and preparation of pipe lengths of the desired length. Places of pipe cuts should be very smooth - this is where a quality tool comes in handy. Cut off the edges should be cleaned with sandpaper and degrease with a solvent.

The third stage is the direct gluing of parts. The glue gun is extremely convenient to use, because it allows you to gently distribute the mass of glue on the surface of the part, but in the absence of a gun, you can use a brush. Glue must be applied in such a way that in the place of gluing there is not a single area free from it.

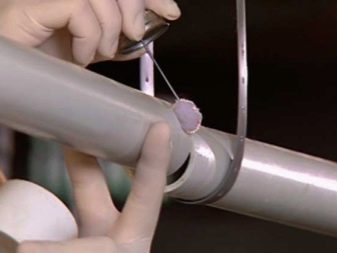

The fourth stage - the connection of parts. Details must be pressed to each other for at least 30 seconds. Glue during this time will begin to thicken, after which the product can be postponed. It is worth considering that the force of compression of the part must be sufficient - otherwise there is the possibility of the formation of leaks in this place.

Glue, speaking out of the place of bonding, must be removed. An ordinary wet wipe, sponge, or any cotton fabric is quite suitable for this. In order for the compound to acquire the necessary strength and hardness, it will take at least 20 hours. At this time, it is forbidden to move products, disconnect them or pipe water.

After that it is necessary to check the connections. The system must be run in operating mode, conducting a thorough study of all joints for leaks. If leaks are found, the connection must be further sealed. When working with glue, the movements must be as clear as possible: a pipe section must be inserted into the fitting in one movement.

Cold welding will allow to mount a very high quality pipeline. The method is quite effective for both water and sewer pipelines. It is applicable both in private and in an apartment building.

How to use glue for PVC pipes, see the following video.