The subtleties of the process of welding plastic pipes

Plastic pipes are a great option for replacing plumbing and heating systems. Their installation is more like a very exciting game than work, and the process of welding plastic pipes differs in many ways from traditional welding processes.

Special features

The welding of plastic pipes is the heating of the edges of parts that are welded to a certain temperature. This process is performed using a special heater and connecting one part to another at a certain depth.

In addition, plastic pipes have some advantages:

- long service life;

- low mass;

- installation work is easy;

- low price;

- do not corrode.

Also, equipment for welding plastic pipes is cheaper than a welding machine for metal structures. In addition, even an inexperienced person can cope with such a process, if there is an assistant.

Details of the design put on the lining, specially made for this. They heat up to the right temperature for some time, after that the parts are removed from the pads and very quickly connected, while they need to be tightly compressed. The edges of the structure are soldered together and form a single whole.

The process of welding plastic pipes has its drawbacks. The main one is the possibility of the formation of flows inside the pipe. They appear in the event that the temperature is too high, and when welding this is not exactly avoided, so you need to carry out all the work very carefully.

Too low temperature will not work either - in this case, the parts simply cannot fully connect with each other. It turns out that it is very difficult to find the optimal temperature for soldering.

Instruments

To perform welding, you need a few tools.

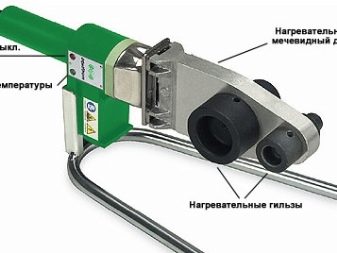

- Welding equipment. This may be a special iron, a welding machine for plastic pipes, or an ordinary soldering iron. You can even carry out this process with a torch or a special gun.

- Nozzles for soldering iron.The most popular ones are models with a size of 20 mm.

- Special battery-type scissors that are electrically operated. Such a tool has a rather high cutting speed. With it, a few seconds are spent on trimming a pipe. If the amount of work is small, you can use a regular saw or knife. Professionals also use special scissors.

- Schweyer is a tool for stripping the contour. It will be needed if the product is covered with a layer of aluminum.

- Pickups. Used with poor contour quality. It is used to ensure that the plastic does not bully. However, if special scissors were used, then it will not be necessary, since with their help everything is done quite neatly.

- Cold welding is needed in those cases, if somewhere there is a leak, and you need to quickly podvarit on site.

- Fittings or couplings. Select them depending on which connection is used.

- Roulette with a pencil or marker. Required for marking cut points and connections.

All tools can be purchased in specialized stores. However, when choosing a welding machine it is worth considering its high price.If it will be used only once, it is better to rent it.

How to solder?

To properly weld plastic pipes with their own hands, you need instructions. First you need to determine where the installation of the pipeline. It is advisable to make a plan so that the nodes to be welded are not located in hard-to-reach places. The easiest way is to assemble the entire structure directly on the table, so that you can then fix it in the already allocated place.

After that you need to prepare a welding machine. It must be installed on a special stand, which is called a clamp. Then you should make sure that its contact surfaces are not contaminated. If the dirt is still there, you need to wipe it with a cloth dipped in technical alcohol.

On the temperature sensor, it is necessary to set the temperature to 260 C. After that, the welding machine is connected to the power grid, and the power button is pressed. Then it is heated for 15-20 minutes. When using for the first time, wait another 5 minutes. The pipe must be cut with special scissors in the marked place. Then a fitting is selected with a diameter of the desired size.It is necessary to insert the end of the plastic pipe and the fitting into the welding nozzle at the same time - they should be in the same plane.

Taking into account the diameter of the pipe, the temperature is added and the time required for this is kept. After heating the elements, they must be removed from the welding machine and immediately connected. Then you need to keep them in the recommended state of time. An hour later, the pipeline is used for its intended purpose.

When the spike is ready, you need to check the node for permeability. To do this, it is blown or let water through it. If the soldering is sealed, it can withstand high pressure.

Welding pipes made of polypropylene is not recommended at low temperatures.

If the temperature is below zero, the plastic will be quite brittle, and the spike will turn out to be leaky, which can lead to both leaks and rupture of the pipeline. To prevent this from happening, a portable stove or a heat gun is installed in a tent at the welding site.

Welding plastic pipes with a large diameter. To solder products of large diameter, the size of which is more than 63 mm, you need to solder the joint to the joint.In this case, the spike is performed by melting the end pipes, as well as connecting them with great effort. You need to ensure that all the ends of the blanks are perfectly flat. Thus, the spike will be the most durable and able to withstand high pressure.

Flame or sleeve spike. Plastic pipes having a diameter of up to 40 cm are soldered using a special manual device. It consists of a centering device, as well as nozzles for fixing blanks. The end of the cut piece of pipe is cleaned with either a file or sandpaper. The welding machine is heated and pushed into it all the details of the future pipeline, and then soldered. Everything must be done quickly, until the material has the required temperature.

You also need to pay attention to the fact that when the flare soldering the inner diameter of the unheated fitting must be less than the outer diameter of the pipe. After welding, it is kept for some time, which is set aside for cooling, and it is impossible to move and turn elements over to avoid deformation.

Welding reinforced pipes. Such pipes are used for heating systems.Before starting work, it is necessary to clean the layer of aluminum with the help of a doorman. This is done so that in the process of operation, in contact with water, aluminum foil could not collapse, and also did not leak.

Welding of polypropylene pipes using an industrial dryer. This method is used only in some cases. For example, to connect two pieces of pipe, to make shaped parts, to make installation of a knee of separate elements. When plastic is combined, the industrial dryer is supplied with a reflector, that is, a nozzle with a special coating. This is done so that the molten metal does not stick to it.

When the dryer is installed on the tabletop, it needs to be set to the minimum airflow. The nozzle is heated to the desired temperature and then pressed against the ends of both plastic blanks. When the polypropylene is softened, the pipes must be connected. Parts are kept in this position for approximately 30 seconds. After that, they stick to each other and harden. Such welding is very strong and durable.

Welding plastic pipes in uncomfortable places. Of course, on direct pipe runs it is much easier to solder.As for hard-to-reach places, in order to avoid unpleasant moments during the installation work, it is necessary to assemble the pipeline directly on the table surface. In those cases when it is necessary to solder pipes in very inconvenient places, for example, under the ceiling or near the battery, one cannot do without the help of another person.

When all parts of the plastic piping are assembled, you can begin to connect the assembly in weight. Here, too, an assistant is needed who will hold the welding machine while the parts are connected. If the assistant also has at least some experience in welding, this can be done alternately, which will make work a little easier.

Everything needs to be done quickly and accurately, and at the slightest curvature you need to immediately replace the damaged element. Observance of temperature conditions is considered the most important point, because overheating of plastic pipes can result in loss of shape, which can be a problem during installation work.

Tips

Starting welding works plumbing with your own hands, you need to listen to the advice and recommendations of specialists. They will help the automatic movements during welding turn into a deliberate process.

If welding works are carried out for the first time, then it is necessary to practice a little before installation of plastic pipes. After cutting the pipes will remain unnecessary pieces that are quite suitable for training. It is necessary to do everything as in the full process.

It is necessary to train until the hand is crammed. If fittings are used, you can solder a couple of items with them. You should not spare one or two fittings for training, because then you can ruin a whole pipe, which is many times more expensive.

It is necessary to buy materials with a small margin, since they can be damaged even before the work begins. Even experienced professionals are not insured against any force majeure, what to say about the newcomer. Therefore, it is better to have some element after the completion of the work

When connecting structures with a small diameter, it is necessary to ensure that due to overheating of the material in the middle there are no sags. In this case, the passage may be blocked, and water will break through in the system. Therefore, before starting it is necessary to blow the water pipes with air.

In addition, there are still many cases where non-compliance with the rules can lead to similar leaks or blockages in the system. For example, improper insertion of the pipe into the fitting, that is, not to the stop.In this case, a gap is formed between the walls of the pipes, and the usual loads will be too large, which can lead to leakage.

You can also test the quality by pushing the pipe or the connection. The design must withstand such a test. If it does not survive, then in the process of operation it will be short-lived. Therefore, you need to purchase polypropylene pipes only from suppliers who have a good reputation - in this case, you need not worry that the structure will eventually bend or break under pressure.

Having collected the entire system, it is necessary to begin its operation no sooner than at least one hour passes. This period of time will be enough to harden the seams. You should not remove the bulges when the welding process is underway - this will lead to even greater deformation of the pipes, while this process will already be irreversible. After warming up, polypropylene cools quite quickly, so slowness in welding is unacceptable.

It is necessary to ensure that the water does not fall into the pipe, because, when heated, it will turn into steam, and the connection will lose its strength. Hot plastic pipes have a very high temperature, so be sure to take precautions.To protect your body, wear a robe and thick gloves - this will save the skin from burns. All actions must be neat and verified.

Starting welding, all joining elements must be cleaned and degreased, otherwise high-quality welding will not work. This should be done immediately before starting work.

Manufacturers of polypropylene pipes say that it is impossible to solder products having different trademarks, because pipes and fittings differ from each other, therefore combining materials with different technical characteristics can lead not only to the difficulties of installation work, but also cause the construction to fail.

In the process of distributing used and pipes, and couplings, as well as turn signals. Therefore, it is worth knowing that the pipes are heated from the outside, and all other elements - from the inside. Do not forget this rule, otherwise the compounds will be short-lived.

After examining all the subtleties of the process of welding plastic pipes, you can easily determine for yourself which version of the process to choose when installing a new water supply system or heating system. To cook such pipes will be for everyone if there is an assistant at home.No complicated machine is needed for work, because only hands and a welding machine are sufficient.

On how to solder polypropylene pipes yourself, see the following video.