Plastic pipes for plumbing: how to choose and install?

Installation of plumbing systems in homes and apartments sometimes raises many questions at the planning stage. It is at this stage that it is necessary to decide which pipes to prefer - plastic or metal, the cost and operating characteristics of which vary greatly. It is quite difficult for a simple consumer to understand all the nuances, so in this article we will try to answer the most common user questions.

Special features

For many years, the main material used for the production of water pipes was steel, but nowadays this option is rarely seen - plastic has come to replace the metal.

The popularity of plastic pipes is easily explained, since this material has quite a few advantages:

- resistance to aggressive environments over a fairly long period;

- plastic is not subject to corrosion;

- high degree of tightness of connections;

- good noise absorption - thanks to this, the sound of the fluid moving along the water supply system is not audible to the inhabitants of the apartments;

- durability - manufacturers claim a minimum service life of pipes of 50 years, which is at least 3 times higher than that of their counterparts;

- environmental safety of raw materials, the absence of harmful and toxic emissions;

- low weight - this greatly facilitates the transportation of pipes and their installation;

- weak hydraulic resistance, due to which the pressure loss is almost minimal;

- availability and low cost of components;

- ease of cutting and fitting pipes;

- possibility of effective hidden laying of water supply.

Among the shortcomings should be highlighted:

- overestimate of thermal expansion and low heat resistance - this requires careful attention when planning work on the construction of hot water supply;

- plastic does not have good plasticity, so if necessary, changing the direction of the main pipeline will require the use of connecting fittings;

- the installation of such pipes requires professional equipment, since the connection requires soldering, which is done using a professional soldering iron with nozzles, and special scissors are required for cutting plastic pipes.

However, equipment for cutting and soldering can be found in any store that sells pipes made of polymeric materials.

Specifications

Technical parameters of plastic pipes are directly dependent on the material from which they are made. Consider the main ones.

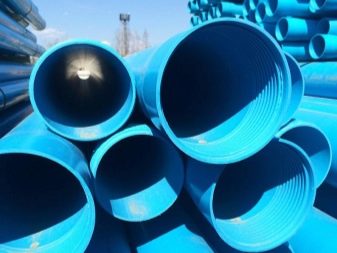

PVC pipes

These are products made of polyvinyl chloride.

They differ in high operational properties:

- tolerate elevated temperatures well;

- keep durability at shock loadings:

- at subzero temperatures preserve integrity and do not burst;

- PVC pipes are non-toxic, they do not stain water and do not give it a peculiar taste;

- chemical inertness;

- antiseptic;

- low weight;

- high bandwidth;

- smooth walls from the inside - this prevents the deposition of lime and other salts;

- fire resistance - the material does not ignite spontaneously and does not sustain combustion;

- long service life;

- possibility of use in soils of rolling type.

Among the cons, we note the following:

- with a decrease in air temperature, the plasticity index is significantly reduced;

- high probability of chipping and scratching during laying;

- the complexity of joining with elements of the pipeline from other materials.

The PVC pipes are painted gray during production, they are manufactured according to the requirements of GOST 51613-2000, the working pressure of the fluid in the system must be within 6-15 atmospheres.

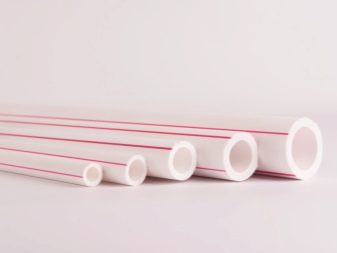

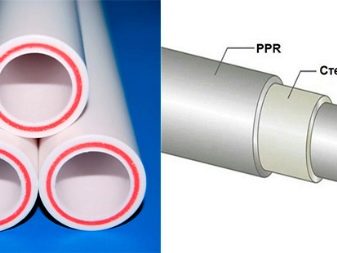

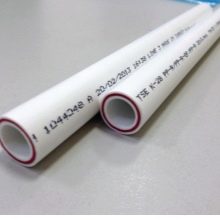

Polypropylene pipes

As the name implies, these pipes are made from polypropylene, which is the product of the interaction of propylene with metal catalysts.

In simple terms, the raw material for the manufacture of such pipes are special white granules, which are melted under factory conditions and extruded through a special extruder.

- The advantages of such pipes include the ability to transport liquids of high temperature - polypropylene becomes soft only at 140 degrees, and melting starts at 175, which meansthat the pipeline from polypropylene can be used both for cold, and for hot water supply.

- This material is resistant to corrosion, and this is its main advantage over metals, which in previous years were widely used for the manufacture of pipes. Experts say that even in conditions of high humidity pipes do not rust and retain their high performance.

- Polypropylene does not conduct electrical current, it can be called an insulator, therefore neither stray currents nor static electricity can cause any inconvenience to users.

- The material is characterized by good wear resistance, the pipes have a rather long service life.

Not without its drawbacks.

- Polypropylene is sensitive to ultraviolet radiation, therefore such pipes should not be laid in open space under the action of direct sunlight, otherwise the material will lose its strength and will turn yellow. However, this disadvantage is irrelevant when it comes to the internal water supply.

- The material is quite fragile.a careless blow with a heavy object, such as a hammer, can easily split them. At the same time the pipes bend quite well.

Manufacturers claim that polypropylene pipes can serve more than 100 years. However, it is unlikely that anyone will be able to verify this statement in the near future, since such pipes began to be produced relatively recently.

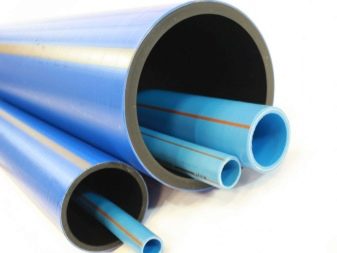

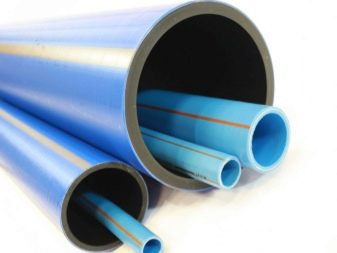

Polyethylene

Such pipes are most often used to supply people with drinking water. Polyethylene pipes are made from polymerized ethylene, such products have all the basic advantages of plastic pipes, but they are characterized by high plasticity.

A distinctive feature of such models is high flexibility, so it is realized not in segments, but in rolls. In addition, polyethylene has a low weight, is characterized by resistance to corrosion, low price and ease of installation.

It should be borne in mind that polyethylene is forbidden to be used for hot water supply, because when heated, the material softens rather quickly and becomes plastic, which causes pipeline breakthroughs.

However, some manufacturers have recently launched production of polyethylene pipes with the addition of special polymers.which increase its resistance to high temperatures - such products can be operated at a temperature range from 20 to 110 degrees and withstand pressures up to 10 atmospheres, which is why they are more often used for the construction of trunk systems.

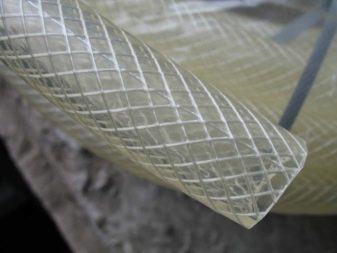

Crosslinked Polyethylene (PEX)

Despite the fact that the main material for this type of product is polyethylene, they should be separated into a separate section, since the special production technology gives them unique consumer properties, which in many ways distinguish them from the traditional options described above.

The term "stitching" refers to a special procedure at the molecular level, it has nothing to do with needles and threads.

Pipes manufactured in this way exhibit high consumer properties.

Increased strength - pipes can last for several decades even under extreme conditions at a temperature of a moving fluid above 90 degrees.

Configuration stability - in the absence of external mechanical action, pipes can retain their original shape, even when the temperature of the liquid rises to 200 degrees.Moreover, cross-linked polyethylene is not prone to cracking, so consumers can be absolutely sure of the reliability of the assembled pipeline.

Flexibility - materials can be bent in different directions and give them the desired shape without compromising their integrity.

Chemical inertness - such pipes can be used not only for the installation of water pipes, but also to create systems for the movement of corrosive liquids.

If we talk about the life of the pipe, then it primarily depends on the conditions. in which pipes are used, namely:

- when transporting a liquid with a temperature below 95 degrees under a pressure of less than 9 bar, the operational period of the pipes will be 15 years;

- with a pressure of 9 bar, and a working temperature less than 75 degrees - service life reaches 50 years.

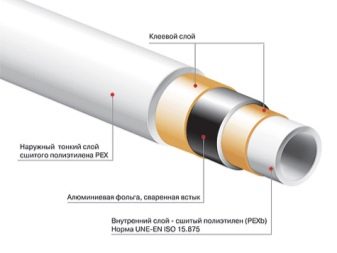

Metal pipes

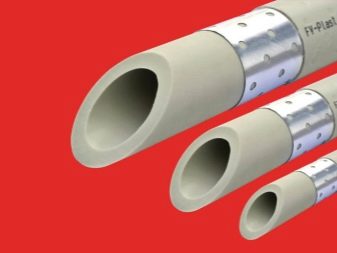

Such products can be conventionally presented in the form of a puff cake, which has several main components:

- inside the water is in contact with food polyethylene;

- reinforcing foil layer;

- dense polyethylene that protects pipes outside from mechanical damage.

Such pipes combine the flexibility of plastic and metal strength., thanks to which they acquire such characteristics as corrosion resistance, frost resistance, the ability to bend in any direction.

Dimensions

When conducting an autonomous water supply system, plastic pipes are selected in such a way as to take into account:

- daily water intake;

- pump parameters;

- the degree of freezing in each specific region;

- groundwater level;

- soil type and topography.

If we are talking about the internal parts of the water supply, then only the first two factors matter.

In plumbing systems, polyethylene coils are most common, as well as pieces of 3–12 meters, which are attached to each other with the help of compression sleeves and electrofusion, which, as a rule, are butt-welded.

External plumbing is usually formed from pipes with a diameter of 32-50 mm, and for arranging internal risers take pipes of 32 mm in size.

Horizontal sections of the highway in the kitchen and bathroom are assembled from 25- and 16-mm pipes.

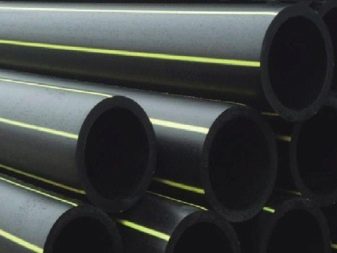

In centralized piping systems, PVC pipes are usually installed with sockets ranging in size from 90 to 500 mm, and in addition, black HDPE 16-1600 mm.

In drainage systems (storm or drainage sewage systems, as well as household drains in the bathroom), experts recommend installing plastic pipes of 150 or 110 mm in size,but for vacuum lines, 50 mm models of PVC or polypropylene pipes are enough. By the way, besides smooth-wall models, corrugated versions with perforations are widely used here.

For horizontally placed sections of pipelines, pipes with a size of 110 mm are taken here, and in the mines of wells, models of polymeric corrugations with a diameter of 600–1500 mm are most common.

The non-operating wells completely consist of a piece of corrugation of suitable length with a size of 300 mm.

For the internal sewer system use pipes of different sizes:

- sanitary siphons with hydraulic locks - corrugation 40 mm;

- horizontal lines - 50 mm;

- plumbing: removal from risers, sanitary pipes and toilet bowls - 100 mm.

For arranging heating systems use pipes with a smaller diameterthan in water pipes, this is due to the lower roughness of the walls, which is accepted by designers in the preparation of hydraulic calculation. As a rule, the diameters of plastic pipes for heating devices are 15 mm, and the wall thickness is not less than 3 mm. Thanks to this size, tangible savings can be achieved at various stages of construction: pipes and fittings of this size are cheaper than more “large” analogues; prone to cloggingwhich significantly reduces operating costs, and in addition a smaller amount of coolant involves the use of a boiler with less power - such products are much cheaper.

A full table of the required diameters of pipelines of all types is available in the existing SanPiNs and GOSTs.

How to choose?

Depending on the purpose, different types of plastic pipes can be used.

For sewage

Pipes for sewage must meet the special conditions of their operation. They must be resistant to aggressive media, such models are often exposed to chemical exposure, so the plastic should not be destroyed under the influence of chemical reactions.

External sewage, as a rule, is carried out in the ground, therefore it is affected by ground mass, creating a high pressure with such loads.

Of course, sewage can carry all kinds of garbagetherefore, the pipeline must be resistant to clogging.

These requirements are met by pipes made of polypropylene with a diameter of up to 150 mm - for a private house and with a diameter of more than 300 mm - for creating drainage systems in industrial plants.

Heating system

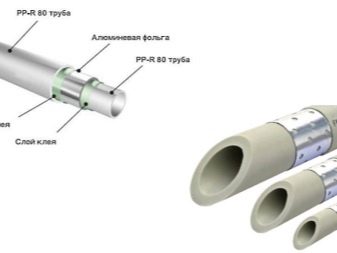

Heating systems made with the use of steel and cast-iron pipes have long gone into oblivion, these materials are distinguished by complexity of installation and high cost, so their use is considered unprofitable. They were replaced by plastic pipes, and to be more precise - polypropylene products with reinforcement.

Reinforcement can be made of fiberglass, in this case it is made inside the pipe, and from aluminum - in this case, the metal covers the car outside.

Fiberglass protects pipes from deformation under the influence of high temperatures, their cost is higher than the material without reinforcement. However, this is not the case when it is possible to save, since only these models can guarantee long-term use of the entire heating system as a whole.

Fiberglass reduces the risk of deformation under the influence of temperature fluctuations and strong heat. Their price is 30-40% higher than the material without reinforcement. Do not save on this. Reinforced guarantee a long service life of the heating system.

Plastic pipes have a lot of advantages, among which are durability, resistance to chemical reactions, ease of installation and low price.

At the same time, we should not forget that if the pipes are chosen incorrectly, you will have to change the entire heating system as a whole, therefore, when choosing a suitable product should pay attention to some parameters of use.

- The pressure that the pipe is able to withstand - this value is indicated next to the marking. Most often, PN25 pipes are used for heating systems - that is, they can withstand pressures up to 25 atm.

- Temperature - if the pipe is marked with hot & cold, then it should be used for both hot and cold water supplies. Some manufacturers simply indicate the maximum allowable temperature.

- Reinforcement - on this factor, we stopped above, experts recommend to give preference to models that are reinforced with fiberglass.

- Diameter - this parameter directly depends on the type of room in which the heating system is installed. In private houses, options with a diameter of 32-40 mm are usually used; when plunging into the radiator, thinner versions of 20 or 26 mm will be required.

Plastic pipes for plumbing

In the arrangement of water pipes, plastic has long and firmly supplanted all other materials, there are many reasons for this - environmental safety, ease of installation, ease, corrosion resistance and low price.

It is very important that the water pipes do not crack or burst at lower temperatures., and when heated, they were not deformed, which is why, when selecting the optimal variant, special attention should be paid to such parameters as permissible operating temperatures and the greatest pressure. In addition, you should pay attention to the manufacturer: products from different factories differ in various design features of products.

If cold water is transported through the pipes, the most common plastic compositions can be used, but other materials will be needed when arranging hot water systems.

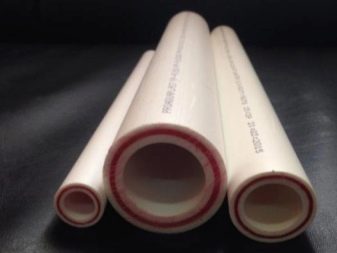

Polypropylene pipes with reinforcement are considered to be the most resistant options that allow you to withstand constant hot flows. Such products are characterized by high heat resistance, resistance to temperature fluctuations. Reinforcement can be, as already mentioned, aluminum or fiberglass. In the first case, the metal can react with water. therefore, its use for arranging domestic pipelines is undesirable; it is worthwhile to dwell on fiberglass.

Using unreinforced plastic is fraught with dangerous consequences - breakthroughs and leaks, since already at a temperature of 90 degrees the material begins to melt and burst. Reinforcement does not allow plastic to expand.

Pipes for floor heating

In such a system, water is heated to a level not exceeding the mark of 40 degrees, most often metal-plastic, polypropylene or polyethylene pipes are used.

Metal-plastic is considered to be a cheap alternative to copper, polypropylene is even cheaper, but it is used much less often due to its reduced margin of safety; therefore, cross-linked polyethylene can be considered the best option. Such pipes are characterized by maximum strength and durability, as well as resistance to heat.

High pressure pipes

Products operated in conditions of high pressure should be distinguished by good resistance to loads, as a rule, they are used for oil transportation, as well as in hydraulic structures and mechanical engineering.

Here, polyethylene three-layer pipes with reinforcement are optimal, such models are characterized by low thermal conductivity, resistance to frost, elasticity and wear resistance.

We draw attention to the fact that such pipes are not suitable for a fire-fighting water supply system, the system does not withstand high temperatures and melts under the influence of direct UV rays, therefore their use in the open air is unacceptable.

Cold-resistant pipes

If it is necessary to equip plumbing in adverse conditions, it should be borne in mind that plastic itself is a rather vulnerable material, therefore in such a situation it is necessary to give preference to materials with special additives.

Most often used pipes made of metal, which can maintain its integrity even at temperatures up to -400 degreesSuch a material does not lose its physicotechnical properties, even if the water inside it freezes.

Plastic pipes for wells

Sometimes it is required to carry out a water supply system from a well or a well, most often these options take place in the dacha and garden plots. The special feature of such pipes should be effective soil containment, so here it is worth giving preference to polypropylene materials.

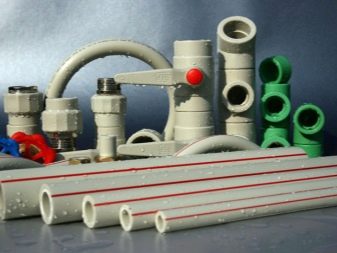

Installation

Installing and replacing a plumbing with your own hands is quite real - the work does not require special training, although strength and endurance will be needed a lot, especially if part of the system is located in the ground.

In the most general form of work as follows.

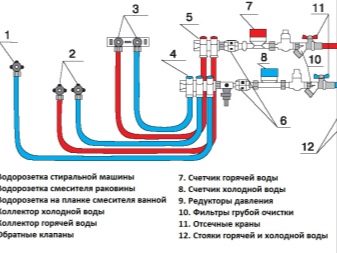

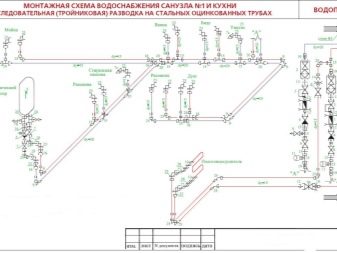

Before assembly, it is necessary to draw up a detailed scheme of the water supply system and think over all its connections, calculate the number of adapters, especially in those places where the transition from plastic to metal is made.

A very important rule that must be adhered to - the system should be as flexible as possible, but the number of nodes in it should be minimal.

Fixation to the walls and the ceiling is made using mobile supports, and fixed ones should be used for such fasteners that are not reinforced by supporting structures, these include various filters, valves, taps and sensors.

If it is necessary to change the pipes and connect them with elements of a metal structure (for example, with mixers or filters), then It is necessary to use combined detachable fittings that are supplemented with metal inserts.

- When forming threaded fasteners, it is not necessary to create a thickened layer of winding or fum tape.

- Tightening of the connections should not be excessive - otherwise the insert will simply slip out of the fitting.

- On long straight sections of the pipeline with a length of over 3 meters, it is necessary to fasten special welded compensators.

- Plastic pipes do not need to be boiled.

Tips

And in conclusion we will give some more recommendations on working with plastic products.

When purchasing plastic for the installation of drinking water supply, be sure to check the certificate of conformity - It is you who will have to drink water later, so the sanitary requirements must be the most stringent.

Be sure to ensure that the wall thickness is constant over the entire length, and the pipe itself is round.

If you see roughness or bumps when viewing a pipe on a surface, then it’s better to buy what you need from another store.

Experts recommend to give preference to products of German or Czech production, their cost is higher than, for example, Turkish, but the quality is much higher.

Recognized leaders of sales of plastic pipes are companies from Germany: Banninger, Wefatherm, and Aquatherm. They specialize in plumbing and sewage pipes. Products of these manufacturers are made in full compliance with ISO 50001 quality systems.

The production located in the Czech Republic - Ekoplastik and FV-Plast are slightly inferior to them. By the way, the pipes of these brands firmly hold a large market share in Russia and other CIS countries and are guaranteed. which is valid for 15 years.

The Turkish giants Kalde, Pilsa, Tebo, as well as Firat, SPK are in constant demand largely due to their low cost. Unlike European manufacturers for pipes of these brands do not cover a ten-year warranty.

In the rating of manufacturers, the closing positions belong to companies from China, Ukraine and Russia, among them RosTurPlast, Teploplast, Karal Plast and others.

How to connect plastic pipes, see the following video.