The threaded connection of steel pipes: features and basic rules

During the repair of water supply, gas, heating, it is impossible to do without docking pipes. But from time to time there are situations when the connection of pipe threads is very difficult. For example, sometimes it is necessary to connect two steel pipes with a square cross section or to connect a metal pipe with plastic without threading and welding - in such cases a threaded connection of pipes comes to the rescue. Consider the features and basic rules for the use of such compounds in practice.

Methods of threadless connections

All methods of connections that do not use threads are divided into 2 large groups: welding methods and methods that do not use threads and welding.

Welding, in turn, are classified into subspecies:

- fusion welding;

- pressure welding.

Bezrezbovye weldless methods:

- coupling using couplings;

- connection using Gebo fitting;

- flange connection;

- tension connection.

Pipe Welding Techniques

Welding is great if you need to make a threaded connection of square pipes.

The most popular welding method is electric arc.

To implement it, you must perform the following steps:

- on the site of the future seam you need to make chamfers on the pipe;

- Mandatory cleaning with sandpaper of the place of the supposed joint (from a large abrasive to a smaller one);

- direct connection of pipes by welding, that is, metal smelting using electric current;

- cleaning the resulting weld with emery paper (from coarse to fine).

The advantages of this method are the relative simplicity of the process., tightness of steel pipes, the ability to use for pipes of any shape and diameter. But it is worth remembering that after welding, residual stresses remain in the welds, which can destroy your joint under high loads or vibrations.Welding is also not suitable for connecting copper, aluminum and plastic pipes. But it can be used to cut the copper or aluminum pipes without waste using autogen, thereby doing the preparatory work for the fitting without using additional tools and equipment.

Threaded connection with coupling: types and their features

Coupling is a cylinder within which the ends of the pipes to be connected are fixed. The coupling is not only a connector (fitting) of pipes, but also an adapter. It can be used for pressure and non-pressure pipes. The advantage of such a connection is the ability to use for all types of pipes with different diameters.

It is worth remembering that the coupling and the pipe must be from the same type of material, otherwise the junction will be unreliable.

Steel fittings are universal, they can be not only a connecting element or an adapter, but can also fix problems with cracks or other damage. Steel threaded couplings are very durable, which increases its resistance to mechanical stress.But you should not use them for pipes that form the plumbing for cold water: because of condensate, corrosion can form and deteriorate the quality.

The name of metal-polymer fittings speaks for itself, they are used if necessary to connect a metal pipe with a plastic one. But at installation it is worth using a sealant. This somewhat complicates the work, because the seal must remain in place.

Coupling with coupling: structure and installation

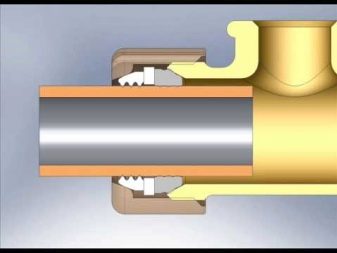

In the general case, the design of the coupling includes a body, 2 nuts of the required diameter from different ends, installed inside the washer, and rubber pads. When choosing such a fitting it is worth remembering that the nuts, washers and linings should be the same diameter as the pipe.

General installation of pipes looks like this: Insert the ends of both pipes through the nuts into the coupling so that they go through the washers and gaskets. Next, tighten the nuts until it stops. The threaded connection with the coupling is ready.

Types of threadless connection fitting Gebo

The youngest and most popular coupling for a threadless connection is a Gebo (compression) compression (clamp) fitting.

This type of compound can be of two types: one-sided and two-sided. In the first case, on the adapter one part is made with thread, and the other part is compression, it is suitable, for example, when connecting a flexible hose or meter to a pipe.

The two-sided Gebo coupling has compression rings on both sides. There are several more varieties of these fittings: in the form of a coupling and in the form of a tee, that is, it can simultaneously use both a connecting element and an adapter.

Device and installation of the coupling Gebo

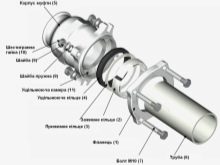

Gebo-coupling consists of the following elements: housing, sealing, clamping, clamping rings and nuts.

Installation of the Gebo compression coupling is very simple, even a person without experience can cope with, usually used for very urgent work.

Installation takes place in several stages:

- sand off the intended joints with sandpaper;

- put the nut on;

- then put the rings on in the following order: clamping, clamping, sealing;

- then put on the Gebo-coupling to half and tighten the nut;

- then do the same for the second pipe or part.

Use of Gebo Fittings

Gebo fittings are excellent for mounting galvanized, cast iron and steel pipes, as well as metal pipes with plastic or polyethylene.

A non-threaded connection with a Gebo fitting is usually used to freeze water in a pipe., the appearance of corrosion or mechanical damage, if necessary, to eliminate the leak. Many masters argue about whether it is possible to use this design of the connection on the heating pipes. The answer is simple: as they say, you can, if you are careful - the temperature of the pipe and the water in the pipe should not exceed 80 ° C at a pressure of 1 MPa, a short-term exposure to temperatures up to 120 ° C is allowed. But the coupling Gebo is great for sewer with a pressure of up to 1 MPa and gas pipes. But in gas mains pressure is allowed not higher than 0.4 MPa.

Advantages and disadvantages of Gebo-coupling

The ease of installation, the original design of the connecting element, the absence of internal stresses and material fatigue, the versatility of the application, and upon purchase you are issued a passport for the part - these are the positive aspects of using a threaded connection with a Gebo clutch. And also such couplings have high resistance to tension and compression.It is possible to connect pipes that do not lie on the same axis, the possible deflection angle is up to 3 °. But still the main advantage over other connecting elements is the lifetime. Gebo fittings can be used from 10 years and up to 50.

The disadvantages include disposabilityotherwise, you will have to purchase additional sealing pads and clamping rings. In various forums, users of Gebo's couplings write that lately fakes have appeared on the market that do not provide reliable connection. Counterfeits are sold without a passport.

Flange connection: types, types, materials of manufacture

A flange is both a type and a method of connecting pipes. They are used in almost all industries, but give particular preference in plumbing. A characteristic feature of all flanges is the fact that they, without exception, are made according to GOST.

The flanges include bolts and corresponding nuts of the same quantity, which are located along the perimeter of two plates for tightening them. Between the plates place the sealing ring.

There are only 2 types of flanges:

- passage flange (they are used to increase the pipe);

- flange-plug (used as a dead end).

According to the state standards of the CIS, the flanges are divided into flat, collar, hardware, ring, for vessels, plugs, on the thread.

Basically, the flanges are made round or oval, but there are also square ones, although less often.

To create flanges, carbon and alloy steels, cast iron, polypropylene, copper and its alloys, aluminum are used.

Flange application

The main task of the flange fitting is to create a tight joint between two pipes with a diameter of ≥32 mm.

Oval flanges are used in communal communications, for example, for sewer pipes and ventilation.

In various areas of production, for example, gas or chemical, only flanges of round shape are used.

Flanges made of alloyed, in particular, stainless steel, are used for pipelines that work with aggressive media (sea water, acids, alkalis, alcohols, petroleum products).

Flanged fittings can be used at a pressure of not more than 4 MPa and with a temperature of operation not higher than 3000 ° C.

With the help of the flange, it is possible not only to make the connection, but also to plug the water or gas pipe.

The unequivocal advantage is the fact that it is possible to interconnect not only steel or cast-iron pipes, but also metal and plastic.

Installation and sealing flange connections

Installation of the flange is very easy. To do this, you first need to clean the connected pipes with emery paper, then install the flange plates on the pipe ends (you can use welding to create a reliable fitting for this operation). Next, put the sealing ring (lining) in the middle of the two pipelines. Then fix the resulting connection with mounting bolts and nuts.

The main characteristic of reliability of a flange fitting is tightness. Depending on the connection medium and operating conditions, various linings are used for sealing. Thus, for the hydrocarbon environment used oil-, petrol-resistant rubber (GOST 7338-77) or paronite (GOST 481-80); at elevated temperatures (more than 400 ° C) - heat-resistant rubber (GOST 7338-77); in aggressive environments - alkali-resistant or acid-resistant rubber (GOST 7338-77); under normal conditions of use - general purpose paronite or fluoroplastic (GOST 481-80).

Pipe tensioning

This option of connecting pipes is used when installing pressure reinforced concrete pipelines when other methods are impossible. This is a mechanical method without threading and welding.

Inside the pipe, a screw motion is placed on the valve with thrust without cutting, then a beam and a wooden beam are installed. At the same time, tightening rods are mounted to the tightening screws and the screw brace.

After the end of the pipe tie, all tension elements are removed.

As a result, a tension connection should be formed. And reinforced concrete pipes are interconnected by means of a valve with thrust, which is held due to internal forces and tension force.

Now you know what methods of connecting steel pipes exist, besides threaded ones, with the help of which you can repair and install a heating system or sewage system without losing the reliability characteristics. Remember that all work should be done very carefully so as not to harm either yourself or others.

For information about the features and the rules of threadless connection of steel pipes, see the following video.