Double timber houses: advantages and disadvantages of new construction technologies

Every builder knows that chopped houses have several significant drawbacks, among which the seating capacity due to wood shrinkage and thin walls are particularly relevant. Therefore, today, special techniques have been invented to avoid the deformation of the structure. They contribute to the weatherization of buildings. The technology of a double bar perfectly copes with this problem. This method of construction began to be used in Russia quite recently, but it has already aroused great interest among developers.

Special features

Houses from a double bar possess a number of advantages before other wooden constructions.As a result, their popularity among construction organizations is very high. This principle of construction meets all standards of heat and noise insulation. It makes the room cozy and reliable.

Structures of double timber have double walls, between which they install insulation materials. 7 cm thick cut logs are connected to each other by the “groove-ridge” method, thus avoiding the appearance of gaps in the wall through which heat is blown out. To date, boards are made, having grooves at the ends, due to which the required rigidity of the entire structure is achieved. However, any design has its positive and negative sides.

pros

According to the owners of houses that built on this technology, there are several advantages.

- Minimal shrinkage capacity due to the use of wood chamber drying. Therefore, immediately after the completion of all installation work, you can live in the house. Shrinkage ranges from 1 to 2%.

- Houses from a double timber provide an optimum microclimate indoors. In winter, they are warm and cool in summer.

- They are characterized by low cost compared tosimilar constructions from other wooden materials.

- The use of natural wood provides environmental friendliness. The material does not contain adhesives, harmful chemical components and industrial resinous-asphaltenic substances.

- These buildings are distinguished by a high energy-saving level, since double bars with insulation do not release heat. Insulating material is chosen in accordance with the standards specified in the requirements for heating.

- You can easily carry out the installation of the structure, which allows to reduce the period of construction of walls.

- There is no need for additional wall insulation, since the insulation is already installed between the double walls.

- The structure is characterized by low weight, which allows not to lay the capital foundation.

- The house has an aesthetic appearance, since due to the presence of special cavities (overlaps, ducts) in the houses from the double timber it is possible to hide wires and pipes. In this case, all communications can be dismantled at any time for replacement and repair.

Such buildings are characterized by a long service life. The estimated service life of the structure is about 115 years.

Minuses

Facilities on the technology of double timber and have disadvantages. Russian manufacturers have several problems.

- With the passage of time between the walls, the insulation material is able to densify and shrink.

- The construction is almost impossible to build independently without the help of specialists, since the necessary processing and preparation of the bars is a very labor-intensive process.

- There is a risk of cracking due to uneven drying of wooden boards.

- There is the difficulty of achieving high-quality assembly. Therefore, it is important to conclude an agreement with experienced professionals.

- The complexity of the selection of insulation as a result of a rich assortment of insulation materials in the construction market is noted. But the professionals have sufficient knowledge to help choose the most appropriate insulation.

Despite the significant shortcomings of the double beam, the main quality indicator is the operational characteristics of the structure. The disadvantages of this technology will appear over time. The most unfavorable condition is climate. Therefore, before construction, it is important to get the opinion of experts and examine all the disadvantages of Finnish technology.

Building on the technology of double timber is not a big deal, but without taking into account all the nuances, you can not count on a good result. For work there is no need for a huge team of workers and the use of special equipment. The main factor when working with double beams is a profiled bar. But the use of wooden boards has certain advantages: convenience and low weight.

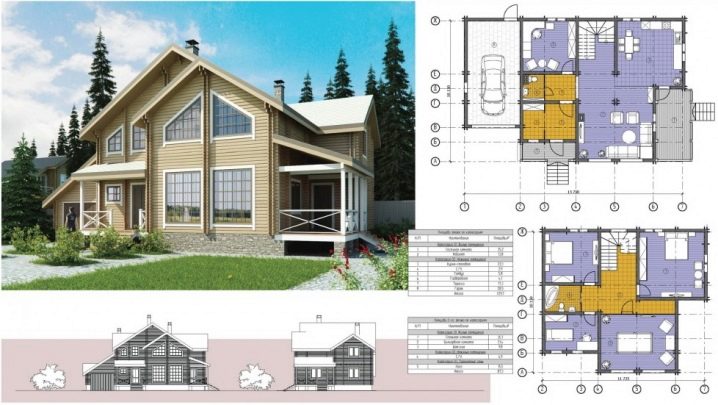

Projects

The design and installation of double timber structures are carried out by companies that specialize in this type of construction. To save money, you can buy a standard project that is suitable for a particular locality, after which it is easy to make some changes. Individual sketches are worked out after researching the entire summer cottage, but the price will be much more expensive.

Construction companies that offer turnkey services to the owners carry out the following services:

- drawing up a sketch;

- design of the working scheme;

- manufacture of parts;

- installation.

The first phase of construction work includes:

- development of an architectural plan;

- designing a house scheme;

- designation of the main types of work.

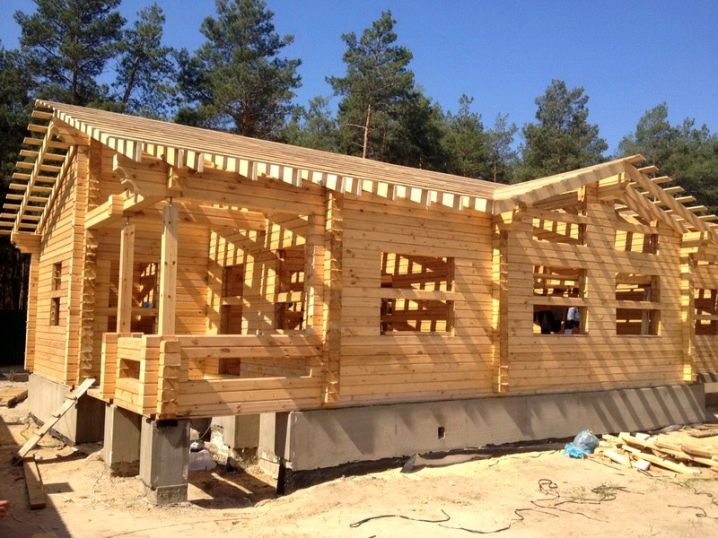

The most important and crucial process is the manufacture of mounting equipment, with which it is planned to build the structure. This process is the longest, it takes about a month. The connection of the individual elements of the structure is carried out according to the lock principle. The construction process is similar to the installation of formwork, but the internal and external walls are the same.

The installation is as follows:

- foundation casting;

- walling;

- strengthening and waterproofing;

- Finishing work.

During these works lay insulation material. It is important to do this in fair weather. Construction of houses from a wooden bar does not allow to conduct the process during precipitation, as the material absorbs moisture and loses its useful properties. The technology of double timber is incomparable with the technology of glued laminated timber, where the insulation is located between two thin walls.

Here the insulation is kept on the bars of 150x150 mm. The most commonly used subspecies of this technology ("double mini-bar"), in which the walls are much thinner, but the construction process is similar. The standard list of services includes the construction of supporting structures, internal partitions, installation of floors and truss system.Sometimes it may be included in the price of the package installation of the screw foundation, as well as the installation of plastic windows and roofing.

More expensive orders include laying all communications. And the quality of work will be top notch. Any owner can choose the most suitable package of services. Disputes about the feasibility of laying a vapor barrier have not subsided, during which some professionals argue about its importance, while others believe that the vapor barrier will disrupt the natural circulation of the air flow, resulting in an increased risk of mold and fungi.

There is also a technology in which the vapor barrier is installed only in floors, and the rest of the structure is insulated at the request of the owners. To save money, instead of ecowool, basalt material is used instead of ecowool, which has the same operational characteristics, but needs protection in order to avoid condensate accumulation.

If the process is not stopped in time, the whole wooden structure will rot and collapse. There is also an option to fill the gap between a double bar with a solution of straw and clay.Some experts do not lay the insulation material at all, considering that an air cushion between the walls does an excellent job with this task.

Technology works

The production of wooden bars for the construction of buildings differs in many respects from the manufacture of core analogs. The process is carried out on special devices - automated cup-cutting lines.

Production of material is carried out in several stages, it is:

- preparation of blanks;

- making holes for connecting boards;

- cup cutting process;

- grooving;

- cutting blanks;

- removing unnecessary parts;

- marking process;

- warming;

- factory packaging.

Construction of the house start with the choice of the foundation Most builders choose the tape version, which is placed around the perimeter of the building. Its depth is 70-80 cm. This foundation will be strong enough and will withstand the construction of a double timber using Finnish technology, as well as help save on building materials.

Prior to the construction of walls, it is necessary to seal the foundation. To do this, horizontally lay boards.Construction boards are laid on them crosswise. After laying one row, it is necessary to eliminate the gaps using foam. When the foam dries, go to the laying of insulation. Ecowool, which meets all the requirements of fire resistance and environmental friendliness, is most often used as insulating material.

Between the boards connect the spikes, which are included in the grooves at the ends of the bars. A heater is installed between the two bars, the inside is covered with a vapor barrier film. Additional strength to the construction is given by the ceiling beams, if they were embedded in the walls. Usually, dry lumber is used, on which the strength of the structure as a whole depends. This is explained by the fact that during the drying of the timber, up to 13% of moisture is lost, which leads to the destruction of molecular bonds.

In the future, the timber will repel that amount of moisture that has absorbed. Therefore, you can not worry about the deformation of the walls. By building a house using this technology, energy efficiency is achieved: less fuel will be used to heat the room due to the ability of the walls to retain heat.If we compare it with brick walls, the thermal conductivity of a double beam corresponds to a brick wall thickness of 1.5 meters. When constructing structures where the walls consist of several ceilings, the question arises about vapor barrier. Without it, do not recommend to carry out construction work.

When using the technology of double timber after a while the walls begin to absorb moisture. As a result, rot forms on the insulation between the bars. Therefore, many homeowners take care of vapor barrier walls and use a windproof membrane, which is placed on the surface of the insulating material. But experienced builders do not agree with this, since the membrane does not allow the walls to "breathe" freely. But since the walls will last a little longer.

Beautiful examples

Finally, you can pay attention to the beautiful examples of finished structures from a double timber.

- The country house, built on the technology of double timber, will be warm and cozy due to the thickness of insulation (up to 15 cm), which will allow to withstand even the most severe frosts. In hot weather, the material will retain freshness and an optimal microclimate.

- Designs from a double bar always look fashionable and modern.Since this technology has recently begun to spread, the house will stand out among others.

- Particularly advantageous to combine the houses of the double timber with high windows. Outwardly, they look presentable, and inside the rooms will be light and cozy.

Overview of technology houses from the double beam, see the next video.