Advantages and disadvantages of houses from profiled timber

Any building, regardless of material, has its own characteristics. This fully applies to structures erected from profiled timber. The merits of such houses, as well as their shortcomings, are constantly heated with heated debate.

Special features

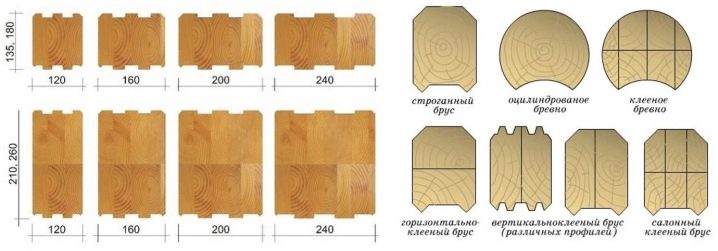

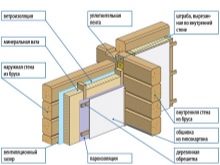

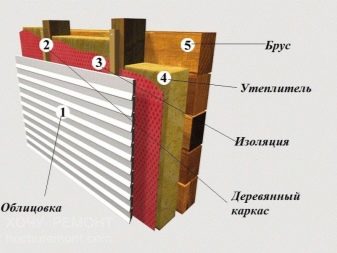

Houses from profiled timber are considered to be very warm for Russian conditions. They either do not need thermal insulation at all, or make it according to the most economical option. Profiled is the type of timber, which, unlike the solid, is subjected to additional formation. On milling machines make spikes and grooves, due to such parts docking is provided. Depending on the design concept chosen by the developers, the sides on the sides can be:

- rounded;

- completely smooth;

- with the addition of chamfers;

- complex configuration of many elements.

Horizontal profiled beam is made by connecting the lamellae in the horizontal plane.

Vertical format involves gluing parts from above to the beam, which forms a hard surface. Salon bar containing six parts, used mainly in the construction of two-story and higher houses.

Like any other wooden product, timber does not give harmful fumes and maintains a pleasant microclimate. Yes, and relatively high strength, along with low cost and affordability is also evident.

Advantages and disadvantages

Natural wood in its raw and even processed form can:

- crack;

- warp;

- suffer from fungal infections.

Technologists are constantly working to overcome these problems, and one of the results of their search was the appearance of laminated veneer lumber. You need to choose only products with international BSH stamp. Processing with special reagents allows you to block the development of mold and minimize the risk of fire. Shrinkage is also insignificant for glued laminated timber, it does not change shape and does not crack.Profiling allows you to achieve increased tightness of products and reduce the severity of cracks.

A special bundle and increasing the closure of the circuit can reduce the heat transfer to the outside and eliminate wind blowing.

But in order to maintain the thermal regime at the recommended level, it is necessary either to install walls from a bar of 400 mm thick, or to insulate more qualitatively thinner structures. Under the bar there is no need to prepare a powerful foundation, light walls will hold well even tape or pile-grillage foundation. Therefore, in comparison with simple log cabins or bricks, the construction budget and time spent are reduced to 20%. Special devices for installation are required in limited quantities, and additional finishing may not be carried out at all.

Unfortunately, there is a profiled beam and serious shortcomings:

- high price;

- lowering environmental safety when choosing an adhesive option;

- a large number of manufacturers that do not comply with technological standards;

- albeit slight, but continuing for several years shrinkage.

A number of adhesives may contain carcinogens.The danger is especially great for mixtures produced in Asian countries - there the control over the safety of products comes down to formalities. It is possible to circumvent these problems, it is only required to purchase complete sets of timber and other elements from suppliers that have proved their reputation. If the order is made for the turnkey construction, it is worth asking about the availability of certificates for all the products used.

It is very important that the profiled timber be made from conifers growing in the northern regions of the country.

There, the natural moisture content of wood is somewhat less than in the middle lane or in the south. The bar of natural moisture is cheaper, but the probability of shrinkage of the structure increases. Surcharge for chamber drying product is therefore fully justified, it almost does not crack and does not precipitate. It is possible to start finishing and settling into the house immediately upon completion of the installation of structures.

The German profile view (sometimes called a “comb”) is formed by sampling grooves and spike connections. But the Finnish version, along with protection from frost, helps to make the shrinkage more uniform and mask the insulation that is laid in the seams between the crowns.

The disadvantage of a profiled bar is that if the storage norms are not observed, its basic qualities may be lost. Air permeability and aesthetics clearly indicate a wood profile.

As for the problems, one can not say about:

- big time for shrinkage;

- the inability to warm the house at this time (will sit unevenly and crack);

- damage to the structure of sawn wood and high rate of rotting;

- the inevitable occurrence of cracks during drying;

- high susceptibility to insects and weather phenomena;

- compulsory weatherization of all year-round buildings.

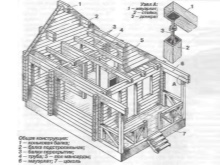

Projects

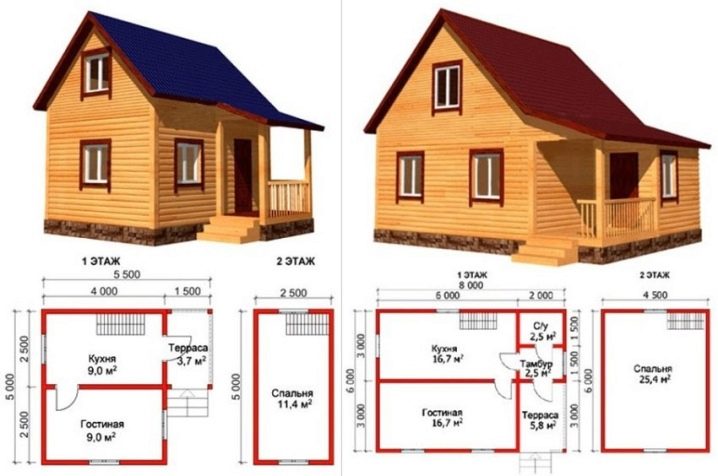

Single-storey wooden houses from a bar with a section of 200x200 allow to provide warmth, comfort and comfort. Insulation of such structures additionally almost not required. All rooms in the building will be fully functional and comfortable. You can use windows up to 4 m high, organize two or even three full bedrooms. Depending on the needs of customers, there are terraces and attic.

It is not necessary to choose options with a simplified view of the exterior decor.

The additional elements that adorn the exterior of the building look very good. What they can be depends solely on the construction budget and on personal preferences. Most customers are satisfied with the imitation of Eastern European style. As a rule, buildings are made of pine or cedar, although other solutions are practiced.

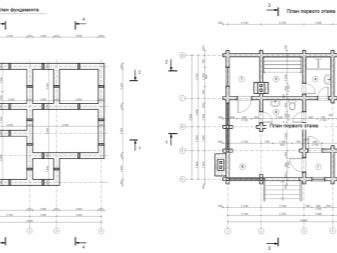

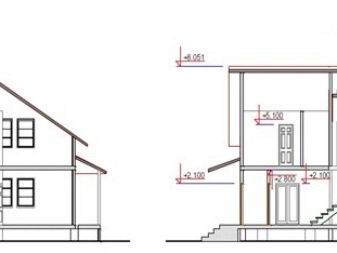

But you can not just confine such general wishes, as well as confuse the project of the house with sketches, sketches on paper. Projects of specialized summer houses with a garage always imply accurate calculations and schemes:

foundations;

- ventilation;

- load-bearing walls;

- overlaps;

- installed communications and other infrastructure.

As practice shows, the owners themselves from the whole preparation can only make a rough draft. But final work on the project should be professional architects. Supplement in the form of a garage should be placed as competently as possible and taking into account many practical nuances. If the proposals of the owners of the site for the location of parts of the building and the distribution of functions are approved by a specialist, then the owners have thought of everything.Primary attention should be paid to assessing the slope of the territory.

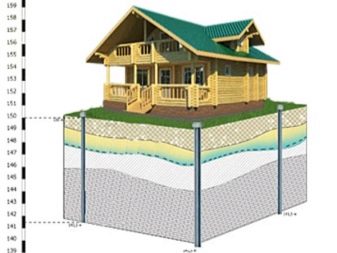

So, if the garage is located in the basement, you need to pay attention to the curvature of the base, the height of the groundwater and the structure of the soil.

The maximum variety of layouts for parts of the house, including the garage, is typical of the corner layout. Parking is most often done from the north or north-west, as this increases the cover of the living space from the winds. The residential area, on the contrary, is released for heating by the sun.

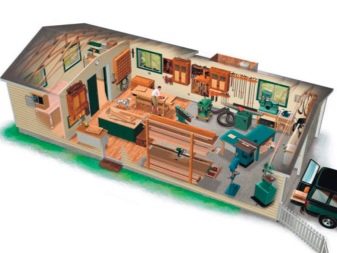

There are projects in which the garage block is combined with a small warehouse or workshop. Regardless, the exit from the house directly to the garage can be equipped, which is very convenient in the sense of saving time and very pleasant in bad weather. Experienced builders always pay great attention to the ventilation of garages.Therefore, this moment should be reflected in the prepared drawings. A two-storey house from a bar for permanent residence can be built according to a standard design, which, in addition to the residential part and parking for the car, usually includes a sauna and several residential buildings.

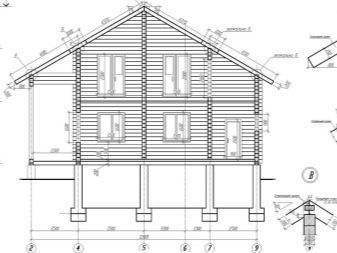

Subsidiary and work premises are placed mainly on the ground floors, and the second tier is reserved for the most part for personal use. Much nicer than a simple house from a bar looks like an option, supplemented by a balcony or loggia. Sanitary units in buildings where workrooms are equipped are usually made of small dimensions. If you refuse to work area, you can expand such a room.

It should immediately think how to solve the problem with the stairs between the floors - they cannot be abandoned, but the absorption of space can be reduced to a minimum.

It is possible to supplement the house from a bar not only a terrace, but also a penthouse. This allows you to extract maximum benefits from the high roof. Judging by the reviews, the best aesthetic characteristics are achieved if the dwelling is located in the middle of the forest or against the background of high bush thickets. The most popular solutions with an attic floor are:

- full-size buildings of the estate type (up to 8x9 or 9x9 m);

- medium-sized buildings - 6x8 m (the cost is immediately reduced by 50% with almost the same comfort);

- the most compact buildings and country-type buildings, the construction fee goes down to 300 thousand rubles or even less - but still this is a full-fledged housing.

When choosing a project of 6x6 m, the minimum amount of decorating parts is usually made, the creation of an external veranda and a bay window is not practiced. The desire to save money and the highest speed of construction requires the abandonment of the broken roof of an elaborate design. Log projects are consistently cheaper, than structures of rounded logs that are comparable in all practical parameters. Style as a whole is more elegant and modern. Chopped construction is sometimes perceived as a simple styling for the old construction, but it does not seem to be capital-looking.

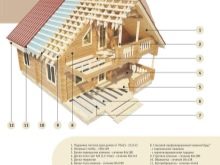

Seeing to be a more solid, timber-based construction, supplemented by an attic and other elements, is invariably lighter and stronger than log structures. And this means that the relief of any complexity will not create problems for developers. Basically, under such facilities is a brick foundation typesetting or pile foundation.

Profiled timber, if it is well-soaked with special reagents, logs are much more effective in resisting the effects of precipitation and sun.

Equally important, the fit to the size of the enterprise allows you to:

- do not be afraid of distortions and gaps in the joints;

- speed up installation;

- less to deal with gaps and technological gaps;

- spend less material on caulker.

The classic version of the house of profiled timber has an attic, bay window; balconies are equipped mainly on the second floors. If the goal is to achieve maximum aesthetics at home, it is recommended to choose a tape base. The visual compatibility of such a dwelling with a pile structure seriously limits its practical application. When increasing the dimensions to 9x9 m, usually a timber is used with a thickness of 20x15 cm, the length of the entire target wall, that is, up to 9 m.

This approach reduces the overall construction time and does not interfere with the strengthening of the structure.

On the ground floors there is a covered terrace, the roofing part of which is combined with the balcony of the upper tier. In addition to simplifying the work, the merging of these parts helps to make the tension in the ceiling evenly. As in most other cases, this project provides for the location of service facilities on the ground floor. The original step is a bundle between the kitchen and the living room, connecting outside the bay window; this makes it possible to use the second floor without crossing the key rooms downstairs.

Dimensions 150x150 are optimal for the realization of any design for the construction of timber. It is enough to learn a few simple rules to complete the necessary work without complicated preparation. The availability of wood (physical and price) does not mean that you can approach it lightly. The material sometimes has natural defects, including knots and bends. In order not to run into problems, it is necessary to carefully study its characteristics and general condition when choosing a raw material.

Construction technology

It is not too difficult to build a house with your own hands from a bar of profiled design. But it will be necessary to pay attention to some technological subtleties on which the quality of the completed construction depends. With independent logging, it is recommended to work in the cold season and expose the raw material to long-term natural drying. This technique allows to ensure uniformity of shrinkage in the volume and the same rate of it throughout.

Important: in case of severe frosts, it is impossible to dry the tree, it can become excessively fragile.

Preparing the profile with your own hands or buying a finished industrial product, you can assemble a house using frame technology. But before building, of course, the foundation. When choosing its type, focus on:

- height of groundwater;

- their aggressiveness;

- structural composition of the soil and its progress.

To find out which solution is better, it helps to get acquainted with the log houses already built in the same area. Most experts offer a choice of tape with a shallow introduction, pillar and pile foundation. The simplicity of the first option turns into a significant cost of materials and an increase in the complexity of the process. The depth of the notch is a maximum of 0.6 m, but it is not recommended to reduce it too. Formwork for pouring the mixture is made either from durable wood without cracks, or from steel, or from special plastic.

Warm the base with EPS plates, and at the corners they should be thicker than in the middle.

Having covered the side walls with resin, crushed stone is poured into the formwork, and roofing material or more modern materials are placed on top. Installation of the first tier of the beam begin only after working out and leveling the foundation; For external walls, blocks of 15x15 cm are taken. To make the floor and walls inside the house, parts of 10x15 cm are used. After covering the baseline with antiseptic mixtures, it is time to assemble the floor logs, mostly they are placed on the edge. Pre-lags for several days incubated at room temperature to eliminate the violation of the integrity of the coating. For warming floors use mineral wool, izolon, foam, expanded polystyrene or (very rarely) sawdust.

Laying of the floor is made with or without offset, the rough base is in any case covered with waterproofing. On top of that, usually, there is a grooved tree with a thickness of 2.8 or 3.6 cm. The batons for a bunch of rows in the walls are made of metal or wood; The second option is cheaper, but not very reliable. The alignment of the dowels is made through 2-3 lanes through one. Pre-drilled holes with a diameter of 30-40 mm.

The next stage after the construction of external walls is the formation of internal partitions.

At least one of them must be present in homes of 6x6 m and more. The cost of the work helps equipment frame gaps, sheathed outside clapboard. We must not forget about the high fire risk in houses of profiled timber. After completion of the work, all wooden surfaces need to be coated with fire retardant using a spray gun or an ordinary brush.

It is worth thinking also about finishing the house outside. A considerable part of developers and even professionals prefers painting. As a rule, street walls are treated with oil-based dyes, characterized by a long service life and increased durability. It is recommended to soak timber with mastics of natural origin. But it is important to note that the darkening of the surface after such treatment will not allow to emphasize the texture of the material.

In winter, the walls are painted with linseed oil diluted with gasoline or white spirit. Particulate debris and dust do not stick to drying oil. Covering the walls with dark mixtures, judging by the reviews, has another negative side - summer overheating. Varnish paints are preferred.because it protects the finished surface more reliably. If there is no full confidence in their abilities, it is better to entrust the production of works to trained specialists.

Tips and tricks

There are a number of points that need to be taken into account, regardless of the recourse to professionals or the independent execution of all work on the construction of a house. The simplicity of the profiled beam should not be misleading: the reviews of the owners of such dwellings show that mistakes lead to serious consequences.

If the project is drawn up independently, even with the necessary knowledge and skills, it is better to consult somewhere for a small fee.

The maximum attention is paid to:

- technological accuracy of laying communications and engineering wiring;

- determining the depth of soil freezing (the foundation must be higher);

- respect the verticality of the outer walls;

- accuracy of setting openings for windows and doors, the corresponding blocks themselves;

- compliance with the period of shrinkage of the building.

It is the violations of the five points listed above that are the main cause of the unavoidable deficiencies of a profiled bar house. It is better to spend a few extra hours on checking the foundation markings, than to spend millions on demolition and rework. Unacceptable savings when pouring the base, as well as the use of very cheap materials of dubious origin. In the construction of wooden buildings it is recommended to use only square timber. He is least affected by the strain.

It is recommended not to reduce to the limit the amount of insulation used, and to choose the most attractive in terms of cost and quality.Then, having determined the necessary quantity and reserve, it is exactly so much to buy. Shrinkage lasts at least 7-8 months, throughout this time the openings are covered with polyethylene and do not conduct any construction work. If you try to speed up the finish and start it prematurely, you can face the deformation of the whole house. BUT it is advisable to start the development of living space in two years.

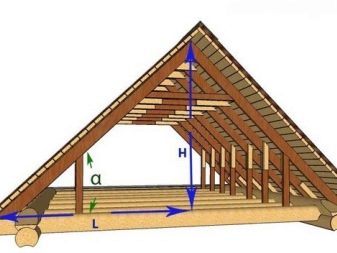

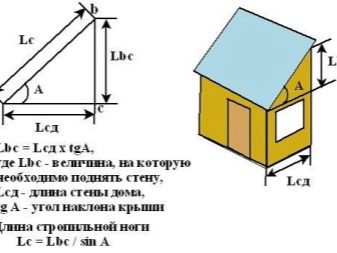

When building a roof, it is recommended to recheck the angles of inclination, not trusting online calculators and own calculations to the end, but consulting with professionals. During the construction of roof structures Be sure to do a strong waterproofing. Most experienced builders put heavy materials, including metal roofing. They look very attractive, press the base of the roof against the wall and guarantee the greatest resistance to weather phenomena. When choosing contractors, it is worthwhile to give preference to even more “expensive”, but experienced teams and companies.

Beautiful examples

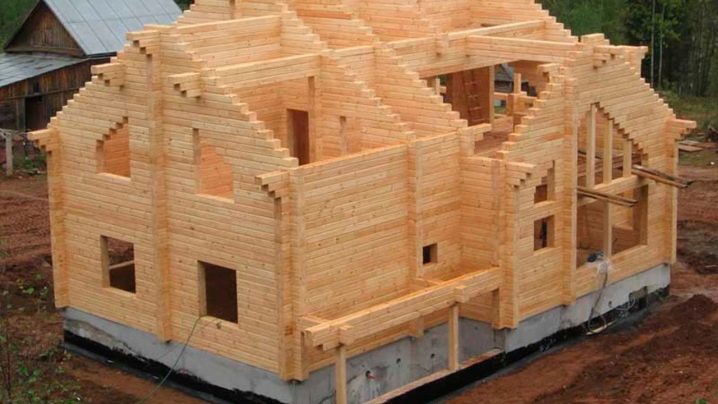

Built of profiled timber can look very beautiful and elegant.Here is a vivid example of this - a house of light yellow wood, with a protruding roof (replacing the actual shed). What is important, its builders took care of creating a curved facade with a number of sophisticated elements. The darker version is perfectly combined with a gable roof covered outside with a metal tile of a refined shade. The curved bars and black frames on the windows create a romantic atmosphere.

This photo clearly shows how graceful a house becomes from a profiled bar due to the selection of a roof of an extraordinary configuration.

Light yellow walls of rich tone and light gray color of the roof covering create a seemingly favorable combination.

And the builders of this two-story house equipped it with an attached terrace. As a canopy, a fragment of one of the main roof slopes has been set up. The basic design idea is a combination of simplicity and grace.

For information on what mistakes should not be made when building a house from a profiled bar, see the video below.