How does the warm corner of log houses?

The coziness and comfortable living conditions of a private house, first of all, presuppose in it a long-term preservation of heat, which is possible only with complete tightness, sufficient thickness of the walls of the structure and high-quality insulated insulation. If more or less everything is clear with thermal insulation and material size, not everyone knows how to ensure the absence of gaps and cracks through which cold and drafts can penetrate into the dwelling. The warm corner, which means the dense joining of the rims of the timber, is the technology that allows you to maintain the necessary heat as much as possible.

What it is?

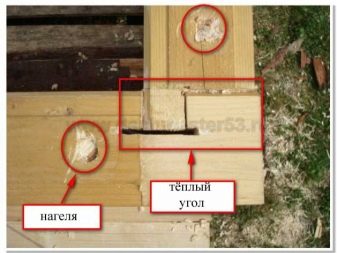

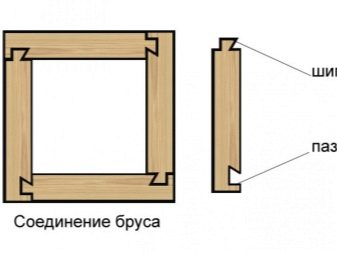

Warm angle - this is a special method of angular connection through the system “tongue and groove”.If the parameters are correctly observed, the angle is sealed, and there are no “cold bridges” in it. Of course, the tree is washed down in such a way that all the parts fit snugly together. To this is added the pressure of the crowns, and as a result the structure becomes more stable and reliable. Based on this, the basic requirements for creating a reliable seal are the following:

- During construction, the strength of a structure largely depends on the total mass of wood and roofing. We must not forget that the operation of such a building is connected with the influence of many factors on the cant: wind, temperature changes, precipitation. Resizing is also associated with shrinkage, wet wood is deformed faster. That is why it is important to build a house of natural material with a moisture content of not more than 20%;

- The second condition affecting the quality of the warm corner is the optimal fit of all the ridges and grooves for the perfect connection.

Due to this, the log house will retain heat even in the winter period and will be protected from freezing and drafts.

In the future, a warm corner can be additionally insulated with such traditional materials as lnovatin, jute, wool felt and even moss.This compensates for the volume of timber when swelling, drying out, prevent rotting or the development of mold.

Technology benefits

The method of such a connection as a warm angle, in fact, has a significant impact on various aspects of construction and operation, namely:

- with a high-quality assembly of the junction of the corners of the walls, it turns out so strong that you can do without inter-heater insulators;

- A building erected by this technology is not threatened by power loads and impacts in the form of soil movement or earthquakes, as it is strengthened several times;

- this method eliminates such unpleasant moments as corrosion, fungus, mold, insect penetration into the interior;

- The cost of fasteners has been significantly reduced, since these fittings are irrelevant when fastening with the remainder;

- prefabricated bars with grooves and spikes cut on them allow for quick assembly.

Kinds

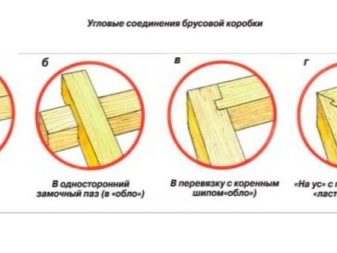

The warm corner ennobles the exterior and interior of the building, since its walls are devoid of irregularities and unnecessary projections. To make a high-quality warm angle, it is necessary to consider different methods of cutting the joints, which have their own characteristics, however, the attachment mechanism is the same.

The main types of docking are the combination of timber with the remainder and without, each of which has several options.

Stacking with residue

Such compounds are called "in the bloom." It has two main advantages - a high level of sealing, as well as the strength of the joint without fixation. This locking system design provides different types of joints.

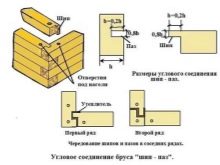

- Unilateral the lock groove is a transverse cut in each bar, while its width corresponds to the same parameter of the bar. It is located at the top and is most often applicable to the profiled type of wood, since it is ideally suited to its design. The grooves are made straight and square. In some cases it is allowed to fasten the connection with the help of dowels.

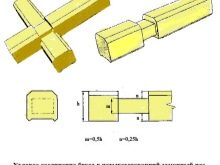

- More difficult is two way connection. For him, the timber is sawn from the top and bottom sides to 1/4 of the thickness. Double fixation makes the structure more durable, which completely eliminates the displacement. An indispensable requirement is a smooth tree structure with no defects in the form of cracks and knots.

- Quadrilateral The connection is the most reliable in the sense of sealing, but differs in more complex preparation of the bars, therefore it is used quite rarely.

Joints without residue

Efficiency is the main advantage of this technology, while the front part of the timber does not protrude from the walls. However, there are also disadvantages of such a connection - it is less durable than with other methods of joining.

There are several options for obtaining smooth corners of log houses.

- In the woodland - this is a docking, in which the bars from one and the other walls are cut into 50% of their thickness, after which these cuts must be fixed with pegs, because such a connection is rather weak. In this case, caulking is later applied. Paw is a similar method, which is distinguished by more complex work with the preparation of the material, due to which the quality of the joint is higher and more durable.

- Keyingthat produce only from solid and durable wood species. They perform the task of the liner in the slots. In fact, the bars are fastened with the side and the end. This mating promotes tight fit and prevents any movement. These parts can be of any shape - oblique, longitudinal and transverse. Particularly relevant keys in the form of a dovetail. Unfortunately, they are difficult to make on their own, because for this you need a special machine.

- The easiest is the warm corner. butt, at the same time it is not necessary to saw a bar.The ends of the material are fixed in a checkerboard pattern using squares, brackets, clamps or metal plates with nails. The bond occurs in length. If wet building materials are used, it is extremely difficult to avoid deformation, therefore, as a rule, thorough cleansing of gaps is usually required in the future. You can carry out the work yourself, but it is better to use dry wood.

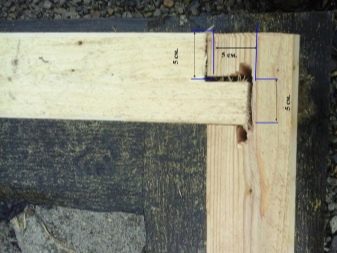

- The most common mount is to root spike. When all the necessary cutouts are precisely calculated, and there can be quite a lot of them, since up to 5 slots and spikes are used, then such a design is the most reliable and stable. At the same time with the connection, a linen or jute insulation is placed in the grooves. This prevents blowing and auxiliary protection is required.

Straight and longitudinal joints also occur in practical construction, but in most cases they represent more complex forms of fasteners, which require a large investment of time and materials.

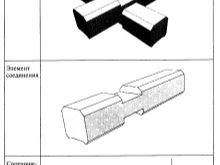

Straight docking is often carried out in the root spike or provides for the joint of the longitudinal beam butt with the help of dowels.Oblique lock, in general, is rarely used, since it is unprofitable in all respects.

Longitudinal fastening is carried out by means of tongues, usually birch, and high demands are made on them - such defects as stratification, knots are simply unacceptable, besides, wood fibers in these hardware should be located only parallel to the axis. Skilled craftsmen, of course, can carry out such work, but does it make sense when there are more simple and high-quality types of warmth?

Useful tips

When cutting a warm corner, you should consider some of the details of the process and the associated problems.

- Since the connection technology already makes the house warm, you should not leave large gaps in the corners for later caulking. Their size should not exceed 0.5 cm.

- Caulk corners can be after several years of operation. If the seams become wider due to the shrinkage of the timber, it is worth bearing in mind that sometimes they may narrow down (when swelling, when humidity is elevated).

- Nails and dowels are not used with technology with the remainder, moreover, their use is a violation of the rules of docking.

- When cutting out thorns they are made in the size up to 1/3 of the beam.A larger parameter can lead to breaking off and, consequently, to a poor-quality connection.

- If the mount is carried out during the construction of the structure of glued laminated timber, for the end use wooden pins with a round cross section for strength. Metallic do not apply, because of the desiccation of the tree, they become too noticeable. To enhance the structure, you can use fastening angles.

- When laying profiled timber, the most preferred connection options are the methods in the root spike, keyway, dovetail.

The warm corner provides reliable protection of the building in the winter and in the summer, in windy and hot weather. To make it, there is no need to call professional builders, because there are simple and effective ways to do it yourself.

To learn how to make a warm corner of a log house at home using thorn-groove technology, see the following video.