Rules shrinkage of the house of timber

For all the buildings of the tree is characterized by such a process as shrinkage. This can not be avoided, even over time the shrinkage does not stop, but only goes less intensively.

This phenomenon occurs due to the fact that wooden building materials have a porous structure, which has the ability to accumulate and release moisture. When this occurs, the reduction or expansion of sizes.

What it is?

The bar is a construction element from a tree. Since the tree is a natural living material, it has properties that are distinctive from others. The main of them is the absorption and release of moisture, which causes shrinkage. Accordingly, shrinkage itself is a process characteristic of any wooden structure, the intensity of which differs depending on the type of wood used.

Most often, the maximum shrinkage give houses and cottages, which are built from a bar of natural humidity.

At the same time, in the case when the wood is drying chamber or glued laminated timber is used, it becomes possible to quickly hand over the building after construction. However, in these cases, shrinkage cannot be ruled out, and sometimes it differs significantly from that claimed by manufacturers.

To minimize this process, during the erection of a log house, compensatory gaps are made in the area of doors and windows.. These gaps are indentations between the box and the wood of 3–4 centimeters, filled with insulation, so that no drafts penetrate through them, and are closed over the backing. In the process of shrinkage, the gaps are reduced and, accordingly, the insulation is compressed. At the same time the doors and windows do not interfere with the shrinkage of the crowns.

However, this process is not ideal. In some cases, the size of the gaps may not correspond to the process. For various reasons, the shrinkage may be more intense than expected, and cracks and cracks may form in the walls.

Experts recommend not to rush and be careful when working with a bar.The ideal option would be not to finish and not to exploit the house for 4–5 months after construction, so that the materials have the opportunity to adapt to the terrain and climate.

This will help the wood to balance its humidity with the environment, and after a given period of time the shrinkage process will be much less noticeable.

Types of timber and the degree of shrinkage

In modern construction of houses from a bar 3 main types of this building material are allocated.

Simple bar of natural moisture

It is used in the construction of buildings and under construction passes the minimum treatment, which includes only obstrugivanie from different sides. Due to the simplicity of this technology, this building material has the lowest price, which makes it attractive in the eyes of consumers.

The wood subjected to such treatment has a rough surface, since it is not intended to polish the surface or make it ideally smooth. Therefore, this building material is used at work stages where its decorative qualities are not required.

If walls are made of such material, they will need additional processing, and you can also use decorative cladding.

If a house from a bar of natural humidity needs to be improved, works not recommended to start earlier than six months after construction, as the moisture content of the material is above 30 percent. All this time the building must be defended. This means that tangible shrinkage will occur, and finishing in the early stages is inappropriate. There is a possibility of processing and grinding the log house, and then impregnating them with an antiseptic, which will relieve the material from the occurrence of mold and mildew, rotting processes, and also scare away insects. Even in cases where the timber must be sewn with siding or clapboard, antiseptic wall treatment also plays an important role in surface preparation.

Under the skin you can put insulation. This will help to more effectively keep the heat in the room during the cold season. To make the house look more natural, with external cladding You can give preference to the internal processing and polishing of walls.

The bar of natural moisture has a standard length of 6 meters. If a larger wall is needed, building materials are butt-packed in a special way. If you need to build a one- or two-storey house for permanent residence, as well as in winter, you should use a bar with a cross section of 150x150, 150x200 and 200x200 millimeters. For country houses suitable wood with a cross section of 100x100, 100x150 millimeters.

It should be borne in mind that any of the above buildings will necessarily shrink.

Natural moisture profiled timber

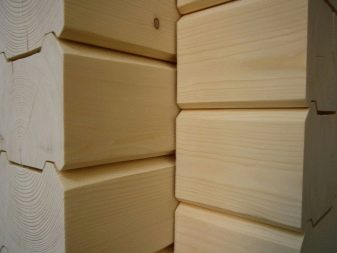

This look passes additional processing, due to which it has a smooth aligned surface. Both sides are equipped with grooved teeth. Products are stacked on top of each other, and the presence of grooves ensures a more tight fastening elements. The moisture content of the profiled material can be from 25 to 30 percent, and maybe even higher. It depends on the time of manufacture, the quality of the wood, the humidity of the environment and other characteristics.

The building is seated for at least 6 months; this is particularly strong in the first 3-4 months after construction.. This timber is more expensive than the previous version. This is due to the fact that the material does not require additional processing. It should only be soaked in an antiseptic solution.. Both outside and inside the walls of the house have a natural woody structure.

The standard length of the profiled beam is 6 meters. The method of laying, if necessary, greater length of the walls is similar to the previous one. Dimensioning also depends on building requirements. The recommended cross-section for the construction of houses in which you can live in the winter begins with a size of 145x145 millimeters. For country houses, you can use sections of 95x145 or 145x145 millimeters.

Glued and dry profiled timber

Such materials are used in the delivery of buildings immediately after construction and their early finishing, since, according to manufacturers, such buildings sit much less.

A dry profiled bar goes through the same finishing steps as the previous one, but with the difference that it is additionally dried in a special heat chamber. Humidity should not exceed 15-20 percent, but due to the property to absorb moisture, which may be affected by precipitation and other atmospheric phenomena, this line can be overcome.

This material has a higher cost, since the structure made from it will sit much less. Shrinkage can range from 3 to 5 percent.

Glued laminated timber has the highest price; it consists of carefully dried wood elements, which are held together with the help of a special very strong glue. Humidity is in the range of 8-12 percent, which, according to the assurances of manufacturers, ensures minimal shrinkage. However, as noted by consumers, even in rooms made of such material, the shrinkage process can be quite intensive, but this is the exception rather than the rule. In such cases, you will need to adjust the rows of timber..

Each of the materials has its own rules of shrinkage. However, experts recommend, in any case, wait a few months, and only then engage in finishing, so that its result will delight consumers for many years.

The following video describes the errors of building a house from a bar after shrinkage.