Warming of the house from a bar: mezhventsovy material for thermal insulation from within

The house from a bar replaced the traditional log buildings. It always reigns a special atmosphere of comfort, and used natural wood provides a favorable microclimate. However, to make the house truly comfortable and warm, it is important to take care of the insulation. Heat-insulating material in such buildings fills inter-crown space.

Types of building material

Timber has several varieties.

- The most affordable - plain or solid (non-profiled).It is a log sawn from all sides, thanks to which it has a square cross-section of 150-220 mm in size. Such material is more susceptible to shrinkage, adverse effects of the environment. Over time, it cracks, due to discrepancies in the geometry and size of individual products in the structure of the gap. This timber is better to use in the event that it is planned to further trim it from the inside and outside.

- Profiled The beam has a more accurate geometry, it is equipped with spikes and grooves. Due to this, the appearance of cracks in the installation process is minimized. Externally, it is more attractive - on the surface there are no knots, blackouts, cracks. Since the profiled bar, like a regular one, is cut from a single log, it also shrinks. However, it is less susceptible to deformation than the non-profiled analog.

- The smallest shrinkage gives the house from glued timber. These are cedar, pine or larch planks fixed among themselves, which are thoroughly dried beforehand. It is drying that ensures no warping. Such material does not need additional processing, it has a convenient fastening system, it has an exact geometry.In comparison with analogues it has the highest cost, however, it cannot be considered completely eco-friendly due to the presence of glue in the composition.

Features of the procedure

The use of mezhventsovy heater allows you to solve the following tasks:

- preservation and improvement of the insulating qualities of the array;

- increase the life of the building;

- prevent ingress of moisture from the outside, mold and fungus;

- ensuring vapor permeability.

Proper insulation of log houses will significantly improve its thermal efficiency, eliminate cold bridges, which always occur between the elements of the timber.

The walls will not be blown even for squalls. Internal insulation will help maintain an optimal balance of temperature and humidity. Wood sensitive to changes in these parameters will not be subjected to deformations due to a significant temperature difference inside and outside the room.

The better to warm?

In ancient times, for warming a log house used waste from household fabrics. They were of plant origin, and therefore were distinguished by safety and vapor permeability.This helped to maintain the optimum temperature and natural humidity in the house. Today, the criteria for quality material are low thermal conductivity, vapor permeability and environmental friendliness.

We must not forget that wood is subject to annual fluctuations in the linear size of the timber (the newly built house shrinks). therefore you need to choose an elastic, elastic material that will be able to shrink and expand without loss of technical properties. Traditional mezhventsovymi heaters are flax (coarse parts of the plant, which remain after the preparation of raw materials for linen fabric), jute, tow and felt (made from sheep's wool). Let us consider in more detail their modern modifications.

Lnovatin

Flax fiber (linen felt) - non-woven material based on flax, obtained by pressing. The release form is a strip with a width of 8.5-200 mm and a thickness of 5-7 mm, rolled into a roll. The standard roll length is 2000 mm. The advantage of using flax fiber for timber is its environmental friendliness. It does not cause allergies, it is made from purified flax (not from industrial waste).

Linen felt has good adhesion and provides a uniform warming of the entire surface of the inter-ring gap. In addition, it has soundproofing abilities.

Using flax fiber allows you to maintain an optimal microclimate in the room. The material takes up excess moisture, with an excessive decrease in moisture content of the air gives it.

It is worth noting the ease of installation of flax fiber.

To give the structure an attractive finished appearance allows the cord of jute, fastened over the insulation. However, if the material is fixed under drywall, the use of a cord can be abandoned. Like any material, linen felt has drawbacks: insects can settle in the thickness of the flax fiber, and mice drag it away.

Jute

This material is a modern mezhventsovy insulation, the basis of which is a recycled annual tropical plant of the linden family. Its unique resins are powerful antiseptic. They protect from rotting not only the heater itself, but also the wooden surfaces of the walls. In addition, the presence of resins makes the material unattractive for rodents.

Jute for timber can be purchased in the form of rolls or ropes. The first varieties have a thickness of 15 mm, their width varies in the range of 100-200 mm, length is 2000 mm. Ropes are often used as a decorative element, since jute has an attractive golden hue, harmoniously combined with natural wood. High tar content has a downside.

The material quickly glues, dries. This leads to a decrease in its volume and the appearance of cracks in the wall. To avoid this, mixing jute with flax fiber allows. The result is flax jute (the percentage ratio of flax and jute is 50 x 50%) and jute felt (the ratio of flax and jute is 10 x 90%).

Tow

This material is based on recycled flax or hemp fiber. The material is less often used for internal warming, as it tends to absorb moisture, rot. Masters do not recommend it for use.

Felt

The material is based on natural sheep wool, which ensures high sound and thermal insulation characteristics of the material. To ensure the biostability of raw materials it is treated with special impregnations. The advantages of the material are its resilience and elasticity. Due to this, it fills the entire space, leaving no cold bridges.

When the house shrinks or wood expands under the influence of high humidity, the felt expands or contracts. This ensures the invariance of its insulating qualities. It does not absorb moisture, does not shrink during operation, is vapor-permeable material. The only downside is the high cost. Available in rolls, whose thickness is 12-18 mm, and the width varies from 90 to 200 mm.

Artificial

In addition to traditional insulation today on sale can be found artificial materials. For example, these include insulating material produced in the form of tapes based on polyester fiber. It has a low coefficient of thermal conductivity, vapor permeability, repels moisture. All this ensures the biostability of the product, its ability to maintain a pleasant indoor climate.

PSUL is a sought-after thermal insulation (pre-compressed sealing tape) based on polyurethane foam, having an acrylic impregnation. Feature of the product is the ability to expand after installation,filling the entire inter-event space. The durability of PSULs is another of its advantages. Its service life reaches 20 years.

Widely used latex, silicone, acrylic sealants, with the help of which it is possible to eliminate mezhventsovye cracks and get rid of cracks in the wood that occur during drying of the material. Sealants fill cracks and free spaces, which prevents the appearance of cold bridges. They do not absorb moisture, but they are vapor-permeable. Due to the elasticity of the sealant, it can be used even in newly built homes.

Use sealant simply due to convenient release form (tuba). Due to the variety of shades, it does not need to be decorated. The material has good adhesion to wood and other materials. This makes it possible to use it in homes with arbolit, foam blocks or other building blocks as a foundation.

An important point - sealants are not suitable as the only insulation with primary caulking. They should be combined with elastic synthetic insulation, as well as used to eliminate cracks in the timber after shrinkage.

Manufacturers Overview

Artificial heaters based on polyester are widely used. The leading manufacturer of such materials is the Finnish company PolyTerm. Trust this product should be already because the wooden construction in Finland is common, and the harsh winters are in many ways similar to the Russian. Material is safe for humans. Even after years of operation, it does not decompose and does not emit toxins.

Despite its artificial origin, the material is characterized by vapor permeability, fire resistance and chemical inertness.

It has a low thermal conductivity and is characterized by its ability to expand and compress. This prevents the formation of cracks due to shrinkage at home. The set includes special shaped elements designed to connect the nodes of the log house.

Products adapted from the domestic manufacturer Avaterm are most adapted to the operating conditions in the Russian climate. It has the same advantages as the Finnish counterpart. The service life of this heater is up to 200 years. The products are designed taking into account the technical features of houses from different types of timber (glued, profiled).

When drilling particles of material are not wound on the drill. It easily passes through the insulation, leaving smooth edges at the perforation site.

Among the reputable manufacturers of sealants for mezhventsovogo insulation can be noted products "Conseal", Neomid "Warm seam", Weatherall and Wepost Wood. These materials are characterized by high performance.

How to do the work yourself?

Immediately after the construction, the inter-spring spaces are insulated from the inside, that is, the primary caulker is carried out. For this, the rolled insulation is twisted and filled the space between the logs with a chisel. Those who do the repair with their own hands, should know that they first caulk the lower link around the perimeter. Only after that you can climb higher, leading work around the perimeter. If at first one wall was completely covered with a single wall, and then the second, it could lead to a warping of the house.

First of all, it is necessary to clean the intervenous space from dust and litter. Next, the insulating material is twisted, applied to the slit and hammered into it with blows of chisels and mallets. Excess material is cut off.

When using synthetic insulation, it is recommended to apply a layer of sealant over them.

A year later, the greatest shrinkage of the house will occur, after which you can begin to warm. Before insulating the walls, you need to check the condition of the wood and inter-linen material. With the appearance of cracks and cold bridges, it is necessary to re-caulk. After that, antiseptic solutions and antipyrine are applied to the walls. In rooms with high air humidity it is recommended to treat the timber with water-repellent compounds (for example, drying oil).

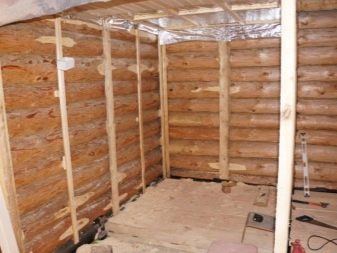

Further internal warming involves fixing around the perimeter of the vapor barrier material. It is fixed with an overlap of 10 cm and fixed with a stapler. Protect the house with a vapor barrier layer is necessary in order for it to breathe, and the wood and insulation are not soaked with moisture vapor.

If you plan to use penofol (insulation based on foamed polyethylene with a foil layer) or mineral wool, a vapor barrier is not needed.

The next step is the creation of crates from wooden logs, pretreated with fire retardant and antiseptic. Their step corresponds to the width of the insulation used. After that, insulation is fixed between the lags.Use mineral wool, tile, bulk or roll materials.

It is important to eliminate in the process of installation all loose fitting joints between the insulator.

If ecowool is used, it is poured into the space between the wall and drywall sheets mounted on the batten. Insulation fills the space after the sheets GKL. Almost all heaters after installation require protection with a vapor-permeable film. The only exceptions are ecowool, mineral wool insulation, penofol. Completing the warming finishing finish, which plays a decorative role and protects the layer of insulation.

The most common option is to install drywall sheets that are plastered. After that, they are ready for wallpapering, applying paint and other contact materials. When internal insulation of the house is especially important to properly organize the ventilation system. This need is due to increased humidity levels after warming from the inside.

Experts recommend to abandon the direct external hoods. It is much more efficient to reduce all the ventilation in the attic and use a small power fan to force the air.

Useful tips

When using a sealant to seal the seams inside the walls, it is preferable to choose acrylic compositions. They are more suitable for interior work, since they practically do not contain solvents and other aggressive substances in the composition. With increased load, you can choose compositions with the addition of polyurethane.

If the house is equipped with a sauna or a bath, it is better to warm the walls with foil-based polyethylene film. The latter will ensure the return of thermal energy, as well as the best protection against wetting.

To see what kind of mezhventsovyh insulation is and what is better, see the video below.