Design of frame houses with a size of 6x6

The frame house 6 x 6 m is a universal project of a small house, which can act as a seasonal country house, as well as a housing for year-round living. Many modifications, second floor, attic, terraces, allow you to make such a "skeleton" more functional and avoid uniformity.

Special features

The frame house basically has a frame on which the main load falls. In this regard, the walls can be made thinner than to increase the internal useful area of the house.

Panels or larger panels are mounted on the frame, so such houses can be made of CIP panels or frame-shield panels. In general, the device elements are similar - between 2 wooden "plates" a layer of insulation is laid, after which they are mounted on the frame.

SIP-panels have smaller sizes and are 2 chipboard panels (plywood or fiber cement), between which there is a heater (foam or mineral wool). Usually it is smaller in size compared to shields, so installation requires no involvement of special equipment.

The shields are assembled at the factory and are a multi-layered cake, which includes the outer and inner sides, between which the insulation and the vapor barrier are laid. Often, these shields have exterior cladding and rough interior trim. Collecting frame-panel houses is faster, however, because of the greater weight of the elements, transportation becomes more complicated, and a crane is often required to attach them to the frame.

Shields can be made in the form of enlarged parts of the house - in this case, they are deaf and equipped with door and window openings. In addition, frame construction can be carried out with the use of panels in a disassembled form - numbered elements are delivered to the construction site, which are assembled by hand. All layers (insulation, hydro- and vapor barrier) are applied with their own hands alternately.

The peculiarity of the frame house 6x6 m is its low weight, which makes it possible to abandon the complex, with additional reinforcement of the foundation. It will be enough to finely recessed tape, pile or slab bases. This kind of foundation allows you to build even on movable soils. You can start finishing immediately after construction - the house does not shrink.

A distinctive feature of the houses on the frame is the high speed of construction and the possibility of year-round installation (the exception - the organization of the foundation is better to lead in the warm season). Similar structures are assembled according to the principle of a children's designer. After the preliminary design at the factory for specific drawings made elements that are numbered and delivered to the construction site.

Through the use of mineral wool or polystyrene, it is possible to achieve a high thermal efficiency of the structure, thereby reducing heating costs. The ease of the foundation, the availability of materials, the minimum cost of construction and the attraction of labor - all this leads to lower construction costs.

The frame house is 15–20% cheaper than analogs made of brick and building blocks.

Projects

The project of the frame house should begin with the study of the features of the soil at different times of the year.It is important to take into account the purpose of the building - the house is intended for permanent residence or will be used as a seasonal building (for example, a summer cottage operated only in summer).

Depending on this, the type of foundation is selected, the specifics of construction technology are determined.

Today, the skeleton carousel can be ordered on an individual project or use standard drawings. In the first case, it will be possible to get the house that best meets the needs of the owners, however, the development of the drawing will be more expensive. In the second case, it will be possible to save money, but in some cases it is possible to forget about the individuality of the structure.

Houses from SIP panels can be rebuilt, make redevelopment. If we are talking about shields, this is impossible due to the fact that these panels are much larger.

When calculating the area, it should be taken into account that a person needs about 15–20 mV for permanent residence. If we talk about frame houses with walls of 6 meters, then more often they are small country houses or houses for permanent residence for 2-3 people.

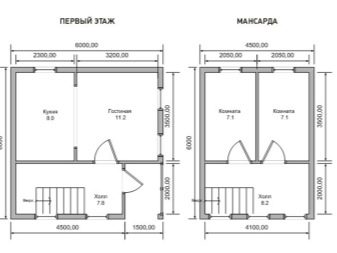

Such structures are optimal for small (3–6 acres) plots.Increase the useful area of the building, without resorting to increasing the size of the house can be, making the second floor. However, the variants of the two-story "skeleton" are not as popular as their counterparts on the same floor as the attic. This is due to the fact that in the second case, the foundation is not required.

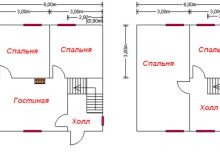

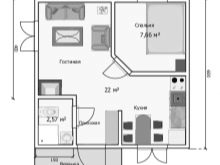

As a rule, the internal plan of a one-story frame house implies a living room, bathroom, one or two bedrooms, and a small kitchen.

The advantage of frame structures is the possibility of attaching to them verandahs or open terraces.

In order to increase the internal space, the living room is often combined with a kitchen, and the attic is made exploitable, having bedrooms there. Another option for planning is to combine a bedroom with a living room, and on the attic floor there is a seating and reception area.

When choosing a two-story building on the first floor usually have a living room, kitchen and bathroom, the second floor is given as a bedroom.

Since the house of 6x6 m can not be called spacious, one should be especially careful in the planning process, including only the most necessary premises in the house. As a rule, for greater convenience, the bathrooms are located next to the bedroom, and the kitchen - from the living room. Outbuildings are best brought outside the house.

At the design stage should consider the location of communications and features of the ventilation system. The latter should ideally combine natural and forced ventilation.

Material calculation

Building a house with a wall length of 6 m is cost effective. This is due to the fact that the standard length of the board is 6 m, that is, it does not require cutting, waste is minimized.

For the construction of the "skeleton" will need the following types of lumber:

- timber of various sections;

- edged board, the cross section of which is at least 2–5 mm;

- rabbeted board with a section of 2.5 mm.

As a rule, to calculate the number of cubes of sawn timber, it is more convenient to use special online calculators, which are offered by many large construction stores.

The calculation of the quantity of lumber should be carried out, based on the drawing of the building, or rather its area. The calculation of the amount of insulation, hydro and vapor insulation also depends on the area.

When calculating roofing materials, it is necessary to take into account how much the roof system weighs, as well as the roofing material used, insulation, as well as the wind rose (that is, the part of the roof that most often has wind load).

To calculate facade materials, you also need to know the facade area, however, to carry out calculations with regard to the batten. It is more convenient if a separate scheme is drawn up for this, since the installation of the batten can increase each side of the house by 7–15 cm.

To calculate the foundation, you must first determine its type. The most economical will be columnar, but it is suitable only for seasonal cottages. If we talk about the pile version, then preference should be given to screw piles. Calculate their number, you know, what is the load from the house falls on 1 square. m

How to build?

The first step in building a house with your own hands will be the preparation of the foundation. For swampy and unstable soils, you can choose a monolithic slab, equipping it with insulating "foam pillows". The advantage of this method is the basement insulation that is simultaneous with the construction. However, the basement in this case will be small - no more than 30 cm. Due to the laboriousness of the process and the high cost, this type of foundation is used infrequently.

More common tape and pile options. The first is suitable for stable soils.The pile foundation will be the fastest and less labor-intensive, since earthworks are not carried out as such.

When constructing a strip foundation for a frame house of 6 x 6 meters on one floor, reinforcement is not necessary, although the armor belt will not impair the performance characteristics of the base.

Further step-by-step construction instructions provide for the organization of the bottom strapping. Geometry of the whole building depends on its quality and evenness of the foundation. When the base sinks or inaccuracies of the strapping, the unpretentious frame house jars, loses its technical characteristics.

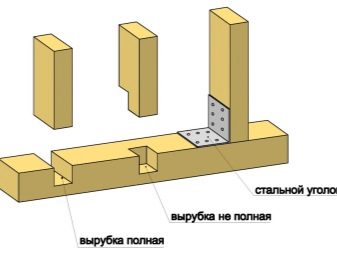

The bottom strapping is carried out with the use of a bar, the cross section of which is 150 x 150 or 200 x 200 mm. It should be well dried and treated with antiseptic compounds, fire retardants. If a pile or concrete foundation is used, a waterproofing layer is arranged between the tops of the piles or the concrete surface and strapping. For this, roofing material is used, roofing mastic.

Bars are laid along the entire perimeter of the foundation and fixed with special anchors. Before inserting a fastener, it is necessary to make perforations under it, both in concrete and in wood.Otherwise (when attempting chiselling), the probability of cracking of the timber is high, which negatively affects its carrying capacity and resistance to the environment. It is recommended to reinforce the corners with metal corners.

Once mounted trim, proceed to the arrangement of the subfloor. To do this, the boards from the bottom are nailed (edged or unedged). Boards are also pre-treated with antiseptics and fire-fighting compounds, its lower part can be painted with any fire-resistant paint.

Theoretically, a rough floor can be laid on top of the draft. However, in practice, such a house will be cold, so a waterproofing layer is laid over the subfloor (the most available option is asphalt resin), and then heat-insulating material (expanded polystyrene or mineral wool). The width of the insulation should match the width of the lag, which will be fixed finishing floor. A vapor barrier film is laid on top of the insulation, and then proceed to fixing the floorboards.

At the stage of organizing a clean floor, all necessary communications should be laid - water and sewage pipes,pipes under the floor heating system, if any.

The next stage is the assembly of the frame, for which boards are used. Vertical pillars, overlapping beams and top piping, as well as pillars and struts above openings, lintels above doors and windows are organized from them.

The frame must begin to build with corner racks, further reinforcing them with truss. For fastening beams, you can use the method of cutting, use steel corners or brackets. All methods are effective and can be combined.

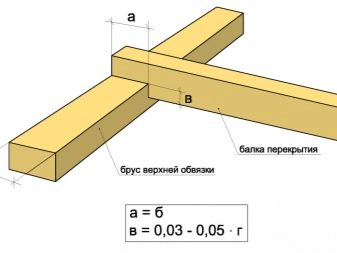

Support for the beams should be the upper strapping bars, beams fully go to the last across the width.

Further the truss system is organized, panels are fixed, the roof is equipped. The latter can act as a heater for mineral wool (for existing roofs), expanded clay or ecowool (for unexploited).

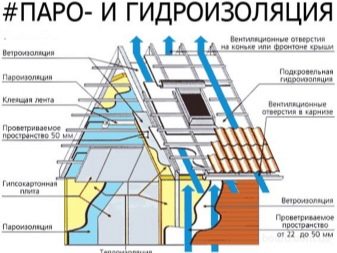

If a house is built from SIP panels, the lining is made on the principle of a ventilated facade., that is, a layer of insulation is being laid, which is covered with a vapor barrier windproof membrane and covered with a covering. An air gap is maintained between the insulation and the facade material.

The same principle is used for cladding shields, if their design does not imply the presence of a facade layer. Siding, block house, clapboard cladding is usually used as a cladding material for exterior finish.

In general, the construction of a frame house with your own hands is a doable task, even for those who have a general understanding of the construction of a house. However, non-compliance with the construction technology is fraught with destruction of the house in the first years of operation.

The most common errors include the following:

- purchase of poor-quality dried wood, which leads to warping of the building, rotting of its elements;

- violation of the technology of the construction of wall surfaces;

- errors in the organization of the frame - excessively frequent or too rare obreshetka;

- Neglect of calculations of the load on the foundation or their inaccuracy;

- subsidence of one of the corners of the basement, the lack of accurate calculations in the organization of the lower trim;

- the absence of additional reinforcement in the corners, places of bridges over the openings;

- the appearance of "cold bridges" in the places of adhesion of insulation to the crate;

- lack of vapor barrier layers, powerful ventilation system.

Beautiful examples

- Most organically small frame houses look in the "village" exteriors. For cladding, you can use boards, eurolining or block house, as well as siding, imitating a wooden or stone surface. It looks interesting combination of 2-3 textures. Increasing the area without resorting to strengthening the foundation and increasing the budget can be done by organizing a spacious porch, open verandas or balconies.

- The chalet style or the traditional Russian interior is also quite simply embodied in the decoration of the "skeleton" 6 x 6 m.

- Connoisseurs of modern styles such as loft, hi-tech, small frame houses are attracted by their laconism, simplicity of geometric forms, and environmental friendliness.

- The frame house in the classical style, which is characterized by rigor and symmetry of forms, elegance, does not surrender. The increasing popularity gain half-timbered "skeletons".

How to build a frame house 6x6, see the video below.