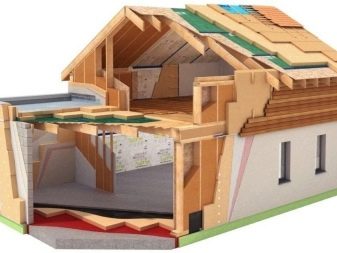

How does the pie walls of the frame house?

The seemingly monolithic wall of any house has, in fact, long been a “layer cake”. This fully applies to the currently popular frame structures. It is important to understand how they are arranged and what influences the technical characteristics of houses.

Special features

The walls of the frame house can be very different in execution, it depends on whether the building is created for city life in the first place or as a summer house. The situation is different when choosing concrete blocks and other standardized materials, there you can vary only the thickness, but not the sequence of layers. In the case of a frame-type construction, it will be possible to use smaller stands and use the available materials for cladding.

It is necessary to take into account not only the responsibility of the created structure, but also the climatic properties of the area.

Device

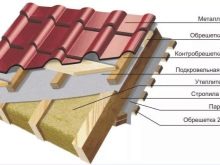

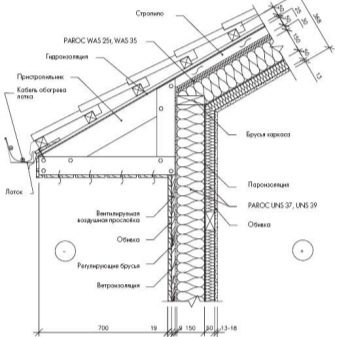

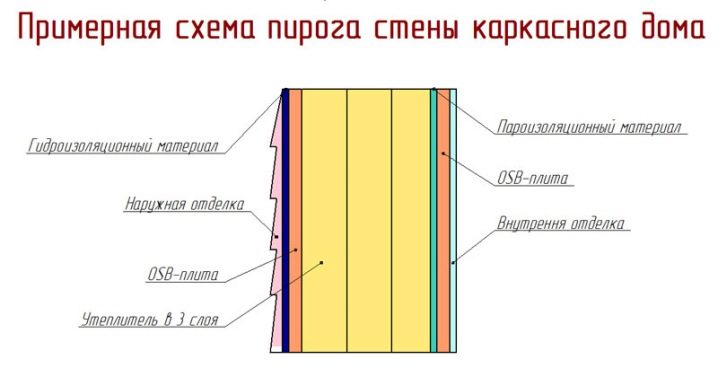

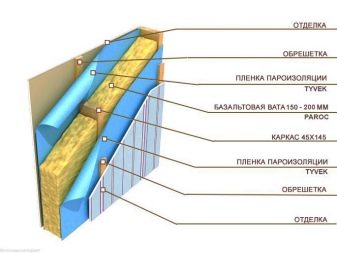

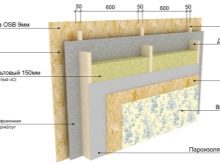

The pie of the walls sheathed by various materials outside, is under construction by the universal rule. Namely: the vapor permeability should gradually increase from one layer to another. Given the low permeability of water vapor to the RSD, it is not recommended to use this material for plating. A membrane is usually placed behind the facial layer, extinguishing the negative impact of the wind. It is desirable that this protection also had the function of waterproofing.

Next is the vapor barrier. As a result, the main task is solved: prevention of the penetration of drafts and precipitation, melt water into the thickness of the wall. And thanks to the vapor-retaining layer, water evaporation does not penetrate intensively enough from the rooms into the warming part.

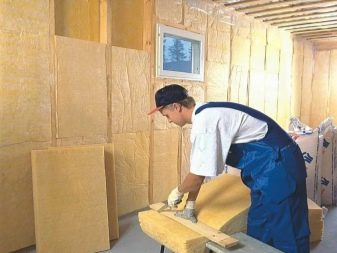

It is recommended to use stone wool as a heater, it will work for 40 years and more. By that time, the finishing materials will either wear out or go out of fashion, and they will definitely have to be changed.

Internal wooden lintels, contrary to some recommendations, need not be equipped. External countering is only required to increase the energy efficiency of the house, helping to block the penetration of cold through:

- overlap;

- strapping;

- crossbars.

The need for such insulation occurs only with a small thickness of the main insulation. To install the above-mentioned jumpers to enhance the rigidity of the frames is necessary only when mounting it on the jib bars. They are mounted on the inner walls when the house is covered with solid plates. When calculating the total thickness of structures, it should be remembered that strictly minimal parameters are recorded in the SNiP. For reference, they are suitable, but builders and experienced customers always carry out calculations on an individual basis to take into account all the nuances.

The right choice can only be made by the owners themselves, focusing primarily on their own tastes, material capabilities and climatic requirements. But long-term practice has allowed to find out some universal requirements and moments. In houses intended for permanent habitation, the walls are made from 15 cm thick. This allows the use of a typical edging board of the most mass format and insulate the wall in a variety of ways. Similar requirements are imposed on those buildings in which they plan to live only in winter.

Summer country houses can do without significant insulation. The lack of heating in winter allows to avoid the occurrence of a dew point and damage to basic materials. You can restrict one layer of insulation, and make the walls about 5 cm. It seems to be all simple, but there is one thing that can drastically change things. The thinner the outer wall, the less its carrying capacity.

The roof, even the lightest and most compact, has a mass of hundreds of kilograms. And the snow drifts will crush from above, regardless of whether someone is in the house at this time or not. In large buildings, it is recommended to install walls of 50x150 mm boards, mounting the insulation in a single layer. This will ensure strength and at the same time preserve the basic qualities of housing. Cottages are built at their discretion, because they live only periodically; but it is better to be safe immediately and prepare a full house with walls from 10 cm.

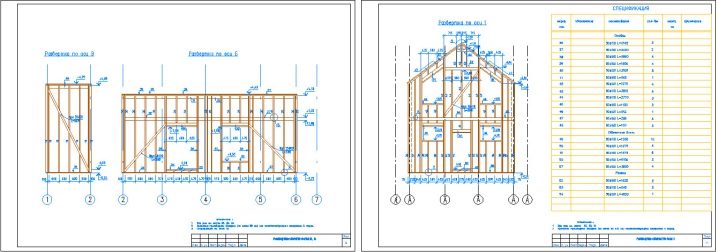

More rigorous estimates already involve the collection of various information, the use of formulas and coefficients, to find all the necessary data is very difficult. For non-specialists it is easier and faster to use various online calculators. If several such resources give one figure, and the builders insist on another, there is reason to think about whether they are “professionals” in fact.There is another method of calculation, based on the sizes of edged boards. They look at the required boards for the frame, form a sketch, determine how window and door openings will be placed.

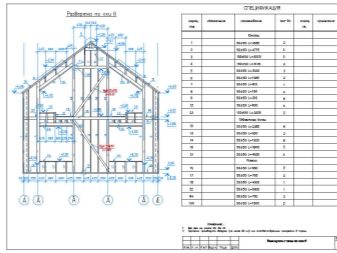

When drawing a scheme or drawing in detail or in the most general form, it is not enough to come up with a “beautiful move”; you should also take care of the maximum reliability of the structure. Need to think about:

- points of use of fasteners and its types;

- arrangement of products and ventilation;

- connecting the wall with the roof and foundation;

- optimal size and shape of windows, doors.

In a good set of working drawings attached to the project, it is necessary to indicate which racks dimensions are used, how far they are from each other, where the lugs are mounted. You should make sure that it shows how the racks in the corners will be connected, whether they correspond to the technology of a warm corner, what will be the junction of the internal walls. Instead of a picking list, real professionals use the exact dimensions of any piece of construction in the same place where it is drawn. As is known, many still include PCB in the composition of a residential frame house, because this material has a number of attractive properties.

In essence, it is the same wood, only stronger and more flexible at the same time.The ease of processing allows you to create even very intricate architectural elements. Sandwich panels, due to the homogeneous structure, do not have voids that inevitably appear in lumber with knots. High density (150% more than chipboard) is also a significant plus, as is the moisture resistance of the oriented plate. When assembling it is permissible to use all the existing types of fasteners.

But even these advantages and the comfortable cost of oriented plates do not mean that we should forget about their low permeability to water vapor. Therefore it is worth looking for a completely different material for the facial finish of the frame house.

When choosing a particular solution and executing it, the following mistakes can be made:

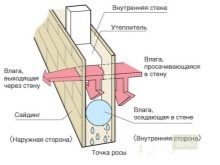

- ignoring the occurrence of the dew point;

- no adhesive tape at the vapor barrier joints;

- vapor barrier insulation structure from both sides at once;

- lack of vapor barrier in principle;

- lack of protection from the wind, or mounting it under the inner layers.

Such moments seem obvious to the limit, but in reality it is precisely these errors that cause so many problems to residents of frame-type wooden houses.It is better not to invent something from scratch, but to use the varieties of “pies” that have been worked out for a long time. Violation of technology leads to wetting of insulation, to the emergence of mold nests on racks and their rotting.

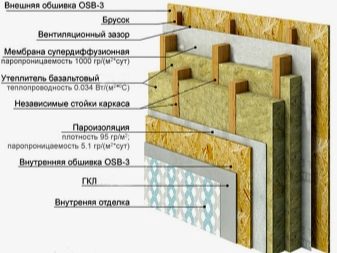

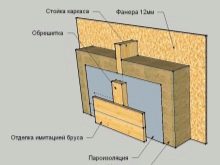

According to experts, the most correct sequence of materials is as follows:

- basic interior wall trim using GCR;

- steam barrier;

- warming layer;

- hard slab material;

- wind protection;

- exterior finish (for example, siding, fixed on the counter-lattice and separated from it by an air gap).

To understand why such a sequence is considered optimal, it is necessary to grasp the essence of the physical processes occurring in the thickness of the frame wall. Water vapor flowing through it condenses (precipitates) from the air as the temperature decreases. In addition to the degree of heating, the appearance of such condensate is also affected by the humidity of the air, both inside and outside. The larger it is, the more condensate begins at a higher temperature.

For vapor barrier is often used high density polyethylene, its thickness is at least 200 microns.

Installation

Attaching a vapor barrier made of polyethylene is made using a construction stapler. Staples are driven into racks every 300-400 mm. Lines of joints need to paste over with bitumen glue. When docking is not overlapped, it is recommended to use a special type of adhesive tape. Instead of polyethylene, you can assemble folgoisol with your own hands.

On top of this material, each joint is covered with butyl rubber tape. As a power plating, fastened inside the house, some experts suggest using not only OSB, but also fiberboard, grooved board or plywood. This solution allows you to create walls with intensive ventilation at the micro level. But full-fledged air exchange can be provided only with the help of real ventilation.

Important: if hard-clad materials are mounted with a gap, additional protection against steam is needed.

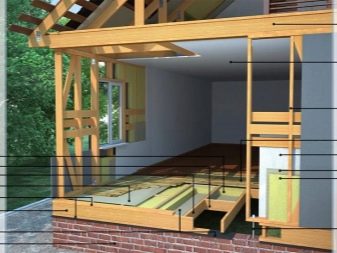

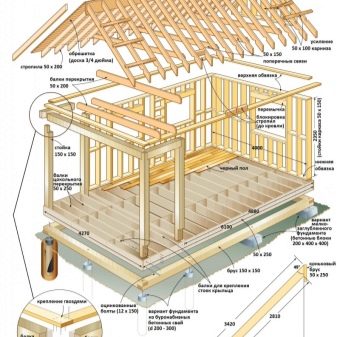

For installation in load-bearing walls used wooden beams and boards, moisture-resistant plywood. The vast majority of developers and brigades make a choice in favor of a planed timber without profiling, made in the form of a square or a rectangle.Products must undergo an active chamber drying, the size of at least one side should be 10 cm and larger. It is possible to tie the bars both with exactly the same products and with the board - the technology allows both. Profiled products have an attractive appearance and help to save, because not only form the frame, but also become internal walls.

The use of laminated veneer lumber has its advantages - high installation speed, and the absence of unnecessary complications. In addition, the force effect and deflection almost do not affect this material.

Important: if waterproof plywood is found in the step-by-step instructions, you cannot confuse it with moisture-resistant plywood. Only the first type of material is acceptable for the design of walls outside. An alternative to these materials and oriented plates for exterior finishing of a frame house are SIP panels.

Industrial manufacturing and a wide range of sizes facilitate installation. In addition, a relatively small mass provides significant savings in the construction of walls and roofs. Bearing and exterior walls are mounted simultaneously. Abandoning special load-bearing walls in a 6x6 m house will not work.Recognizing the need for this element is not difficult: if you can rely on the outer walls with the ends of genital lags without deflection, there is simply no need for supporting structures.

Both in external walls, and in interroom partitions sound-proof material can be used. The differences are that inside the house - this is less relevant.

In addition, you need to think about the combination of thermal and acoustic properties in one substance, this will allow:

- reduce costs and thickness of structures;

- facilitate them;

- simplify installation.

Filling of bearing walls with insulation may be partial, but care must be taken to securely join the mineral wool with the structure. This is achieved by increasing the number of brackets in the upper part and along the perimeter in comparison with the insulation of the sides of the house. The distance between the brackets is exactly 100 mm. A membrane or other fabric as a protection against noise is suitable for load-bearing walls relatively well. When a dwelling is heated on either side of such a wall, it is acceptable to use roof paper.

Contrary to popular opinion, the strong unpleasant smell in a week will cease to excite residents.But the savings will please them for a very long time. Attach sound insulation helps construction stapler. On top have inch boards, the intervals between which are determined by the type of finishing material. For gypsum boards, as well as for lining, leave a gap of 600 mm between the middle of the boards; the lower and upper boards are placed regardless of the interval.

It is very important to fix the description of the appearance of the batten on paper and photograph it in high resolution. When you need to screw hardware in the wall, there will be no need to act by trial and error. At the points where you need to gain, it is desirable to fill the board immediately. This refers to the attachment points of any hanging cabinets, large shelves and mirrors. Returning to the interior partitions, you need to say about the two methods of their creation.

In one case, power elements are placed in the interstices of genital lags, and the boards are already mounted vertically on them, becoming a skeleton. In another approach, the pillars rest against the floor or planks, nailed to the floor. Regardless, the most reliable solution is attaching the upper ends of the racks to the sex lags or replacing them with specialized structures.

For your information: it is worth thinking at the same time about the correctness of the lines of the rooms, and about the additional reinforcement of the frame elements, the overlappings when placing the racks.

Most builders and architects believe that for internal partitions it is not necessary to take boards thicker than 10x5 cm. After all, all the same to this indicator will add more decorative trim. Racks of interior designs are spread by 120 cm, since this is the typical width of mineral wool products. The use of natural basalt wool is justified inside only by increased concern for the environment.

Tips

It is undesirable to save on the boards, because the lumber of natural moisture, not planed, is extremely bad. Serious builders even believe that it does not fit at all. And this opinion is quite reasonable - there were cases when the raw material led to the appearance of mold. This forced to remove the vapor barrier, to process everything with antiseptic and wait a long time for complete drying. As for the section, the minimum dimension for a frame wall is 15x4 cm.

The internal vapor barrier must be laid under the subfloor so that the insulation is not open inside. This will lead to the fact that at the very first frost condensation and frost will arise, and gradually they will grow. Since most types of thermal protection are available in a width of 0.6 m, it is desirable to make racks for their fastening one centimeter closer. Then the mount will be perfectly durable and reliable. It is recommended to place rigid boards under the drywall inside the frame, at least a particle board, and ideally oriented or cement-bonded structure.

For more information about the "pie" of the walls of the frame house, see below.