How to make the lower and upper trim frame house?

The frame construction of a private house implies the presence of lower and upper trim. They are necessary to ensure the strength and reliability of the entire structure. With the correct implementation and compliance with all the subtleties, the frame construction of the house will serve you for many decades.

Lower strapping is the basis of the frame construction of the house, assembled with the help of boards, logs or lumber. Lower strapping is performed to ensure reliable fixation of the structure to the foundation.

The installation work with the frame structure can be started only after the installation of the lower screed.

Construction Materials

With the implementation of the lower strapping for the frame house can easily cope on their own, while not resorting to the services of specialists. When performing installation work in strict sequence and compliance with the recommendations of the difficulties should not arise.

It is recommended to give preference to coniferous wood as a material for the lower trim. Conifer has a number of advantages that exceed the positive side of hardwood.

The main advantages of coniferous breed are:

- high strength;

- sufficiently long service life;

- water tightness;

- smooth tree trunk.

To install the bottom trim most often choose larch, Norway spruce, fir or pine. It is worth noting that the wood should be chosen according to the location of the future structure and the environmental conditions in this region.

In addition to the choice of wood for the lower screed, you will need to decide on the form of lumber: bars, logs or boards. When choosing the last variant of the board, it is recommended to fix with screws with different diameters in a checkerboard pattern.

Before installation, all construction materials must be subjected to two-stage processing.

The first stage is carried out with the help of a special antiseptic agent, which prevents the material from rotting and the occurrence of fungal deposits. After the material dries, it is processed using a special tool called a flame retardant. It increases the refractory characteristics of the material, which prevent the fire structure. Due to the huge amount of wood resin, processing using a flame retardant for coniferous wood is the most common procedure.

Slinging floor can be done by hand. Make it not difficult if you follow our recommendations.

Double construction can be performed on a columnar foundation or screw piles.

Bottom trim installation

Sometimes the bottom screed is made with a metal profile, but in the case of a frame wooden house this solution is not suitable. The installation of the bottom trim of the frame house occurs in several stages:

- selection and installation of the foundation;

- preparation of necessary building materials;

- installation and connection strapping.

For the bottom trim, you can select and install any foundation, for example, a charging option. But in most cases, preference is given to the pile foundation.

The fact is that for this type of foundation is characterized by quick installation and reliability of floor construction.

Even at the stage of installation of the pile foundation, it is extremely important to check the uniformity of the installed base and create a waterproofing layer using roofing material or bitumen, as well as the scheme. In addition, it is necessary to provide special mechanisms for fastening the foundation to the bottom screed. To accomplish this task, it is recommended to use an anchor bolt or a special wooden cork.

Second phase - preparation of the necessary building material - begins with pre-drying wood. Next, you need to pick up the corner part and determine the method of the mount: in the wood floor or paw. The first option involves cutting out a special rectangle. In the second variant, sawn timber cut occurs at an angle of more than ninety degrees.For the manufacture of grooves used electric planer.

For the implementation of the final stage of the installation of the lower trim, you must outline the corners of the future construction. For starters, the point taken as the first external corner of the future structure is marked. At this point it is necessary to drive a nail. Other corners of the structure are marked in the same way.

After using the carpentry triangle, check whether the right angles have turned out. If necessary, correct the location of the nails.

Then you can proceed to the installation of one corner of the future construction and laying of selected lumber. In the course of work, emerging joints are recommended to be laid with jute tape. It is necessary to create a strip between the lumber. If you use a bunch of boards, it is recommended to make their laying on the edges. So all the connections between the lumber will be in a vertical position.

On a straight section, the harness is connected with a jute tape by means of a front stop. Frontal stop is considered one of the most simple and reliable connections, which is used for a large number of wooden structures.Fastening strapping occurs with the help of brackets or parts of metal.

During the laying of elements of the strapping, using the building level, check all the corners of the building and their horizontal position.

In order to fasten the lower trim to the foundation, use the following two methods:

- Anchor bolts pre-installed in the foundation are fixed at the base of each pillar or over the entire area of the strip base.

- Nails, which were also pre-installed in the foundation before the start of work with the bottom trim, are driven into the cork. This method is more reliable and high quality. It is recommended to additionally check the obtained bottom piping for uniformity using the construction level, after which the lag is set.

If a tape-type foundation is installed in the building, then the lower frame of the frame house is much easier. First of all, the tape type of the foundation assumes the presence of a solid concrete tape with a flat horizontal. It is to her and the bottom strapping will be firmly fixed. A waterproofing material is laid on the concrete tape, and then holes are made for corner joints.

Timber is fixed with studs, bolts or anchors. For the strength of the joint corners, it is recommended to check whether the sawn timber is evenly spaced. If necessary, using wedges or linings, their location is adjusted. Installing the log is carried out by any method convenient for you.

Today the construction market has several different technologies for the construction of a frame house. And for each technology has its own building material, which will determine the final cost of construction of a frame house.

Assembly lag

It should be noted that the lower piping is not only a support for the walls, but also the basis for the future floor. Lags for the floor in a frame house are edged boards with a width of fifty, two hundred or two hundred fifty millimeters, which are mounted on the ribs.

Bottom trim, made of coniferous wood, greatly facilitates the further installation of the log, additionally giving the design reliability and durability.

To date, there are three commonly used methods of fixing the lag to the bottom trim of a frame house:

- The first method is based on parallel bars.For strapping fixed bars located in the lower part, and they are based on the ends of the lag. This method will require the purchase of additional attachment to the lower strapping for the lag. Since the bars act as a support, they do not form bundles with the foundation.

- The second method involves the use of a metal plate or corner. This method is characterized by a reliable connection of the frontal surface with strapping bars. However, there is no support in the lower part, the lags “hang” on the metal plate.

- Mounting a lag on top of the bottom trim using it as a support. This method will allow you to firmly connect the logs with the lower strapping, while creating a high-quality support joint and structure.

For the installation of racks for frame walls will need additional bundles made over the lag.

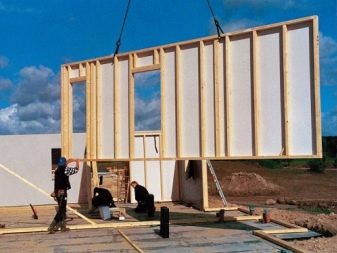

The most convenient option for the construction of a frame structure is the platform method. For this, the frame structure is pre-assembled in a horizontal position. After that, it rises to a vertical position and is installed with support on the floor.

Often, either the platform method or the combination of the first and second methods (support bars and metal fittings) are used.This will strengthen the mount between the lags and the lower strapping and simplify the further installation of the lag. The interval between lags in frame houses is determined by the width of the dwelling and the calculated loads on the lags. In other words, the smaller the distance between the spans of the lag (walls), the greater the interval between them.

Installing the top trim

The top trim of the house is recommended to be made from the same building material used for the manufacture of the bottom screed. This is necessary to maintain the same cross section between the straps. In addition, in the future, it will facilitate the process of covering and warming the wall surface.

At the corners the lumber on the top trim is joined by cutting. Fastening to vertical racks is carried out in the same way as in the case of the bottom strapping. When used as a fastening metal corners fixation occurs using screws.

Before you choose the method of fixing the cutting, it is recommended to make grooves for each rack. It is very important that all the grooves made are located strictly under the grooves of the bottom trim.

Compliance with these conditions will allow to achieve a smooth installation of vertical racks.Otherwise, you risk getting skewed racks, which adversely affect the frame construction of the house.

Fixing lumber with frame construction is carried out with the help of nails. Make sure that the nails are at the base of the rack for at least ten centimeters. To preserve the rigidity of the frame structure of the house, the upper trim is performed with a diagonal brace. They are designed for unloading the connection of the longitudinal and transverse beams.

It should be noted that the technology of frame construction is one of the simplest and low-cost construction methods for residential and non-residential buildings.y. Due to excellent thermal insulation, the frame house has a comfortable and high energy efficiency.

The production of lower and upper trim for frame houses plays an important role. It allows you to ensure sufficient strength and reliability of the frame structure, in connection with which it is recommended to make strapping, observing all the technological standards and rules.

How to build a frame house with your own hands, you can find out by watching the video a little lower.