Features of the Canadian technology for the construction of frame houses

The frame system is becoming increasingly common in private housing. This is due to the ease of installation, efficiency and efficiency of the construction process. One of the most famous technologies of frame construction is Canadian.

What it is?

The peculiarity of frame houses is that the main supporting element are frameworks (columns), and not walls. As a rule, in the construction of high-rise buildings and public facilities they use monolithic-frame technology, pouring concrete solution into metal bases. Owners of private houses prefer to use wooden or metal structures.

For a long time, frame houses in Russia were biased, considering such objects to be cold and unstable. In many ways, this attitude is due to a violation of the construction technology when attempting to self-erect or to turn to unqualified professionals.

At the same time, in Canada and a number of progressive European countries, up to 80% of private houses are built using this technology. It is not surprising that for the entire period of its existence this method has been maximally improved.

Canadian technology (along with the Scandinavian) is considered a reference. Observing its principles, it is possible in a short time to build a reliable and warm "skeleton", not inferior to the stone house by these criteria.

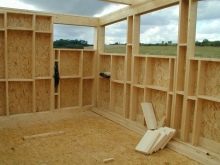

The basis of this structure is a frame consisting of horizontal and vertical profiles, which are interconnected according to the principle of the designer. Hollows having a frame are filled with insulation.

The design is characterized by low weight, so lightweight foundations can be mounted under it (belt, columnar or finely recessed base plate). The choice of the base is wide enough and must necessarily be conducted taking into account the characteristics of the soil.Provided that a suitable type of foundation can be erected using Canadian technology, it can be erected on unstable soils and soils with a close location of groundwater.

The ability to abandon the complex, additionally reinforced foundations, allows to reduce and simplify the construction process, reduce the estimate.

You can work at any time of the year. On the basis of the frame they build houses of several floors (up to 2-3 for a private house), which can have a diverse configuration.

With a relatively small thickness of the walls (compared to brick, for example), they demonstrate good performance of heat and noise insulation, although without a heater, the operation of such a house would be impossible. The only exceptions are houses made of SIP panels, based on panels made of pressed “warm” materials, supplemented with a layer of polystyrene foam insulation.

Thinner walls (especially if they do not need to be further insulated) make it possible to get more usable area. So, if we compare the "skeleton" and a brick house of the same size, it turns out that the internal area of the first is at least 5 m2 larger.

The technology developed and applied in the countries of North America is suitable for construction in the climatic conditions of Russia. Homes are characterized by weather resistance, withstand hurricane winds, are not afraid of frost. They are even suitable for installation in seismically active areas.

Among the minuses of the object is its flammability, since in their fire safety at home they are like wooden buildings. Surface treatment with a fire retardant, use of plaster or coatings made of fire-resistant materials as exterior coating can reduce the risk of fire.

It is important to process the fire retardants not only the erected structure, but also the elements of the frame in a disassembled form. Optimally, if each element of the frame in disassembled form is treated with compounds that increase the fire resistance. After the procedure is repeated already for the assembled frame.

With the observance of the technology of construction and the use of quality materials, the service life of the structure reaches 50 -70 years. Often, the description of the original Canadian technology contains references to the possible 100-year operation of the object.Of course, the durability is affected by the operating conditions and features of the project.

Sometimes frame houses are called environmentally unsafe. This quality is most likely due to their persistent association with chipboard materials from the Soviet period (based on toxic adhesives).

However, modern resins and hardeners are safe for humans. In addition, they scare off rodents, making the elements of the house unattractive and overly durable for the penetration of mice and rats.

However, the presence of vapor barrier film, insulation (especially polystyrene foam) and other synthetic components does not contribute to the formation of a favorable microclimate in the room. However, this remark is true not only for frame houses of the type in question, but also for most modern buildings. To solve the problem allows well-designed ventilation system.

Projects

A feature of the frame object on the Canadian technology is a frame made only from dry boards. They can be double or structured, but in no case should they be replaced with a bar.To strengthen the structure (for example, in the area of openings), you can use not only doubled lumber, but also a hider (a board mounted on the edge).

OSB - plates, the thickness of which must be at least 12 mm, are used as plating. The plates are stacked, taking into account the deformation gap - between them there is a space of 2-4 mm. Plywood sheets may be used on the roof (if the distance between the rafters exceeds 60 cm).

As a vapor barrier material, Canadians choose thick (150-200 µm) polyethylene, overlapped and glued at the joints and damage points. Laying vapor barrier is not provided between the 2 warm floors or adjacent heated buildings.

As a heater mineral wool is more often applied. Polystyrene plates are in demand only if the walls are too thin, that is, where the thickness of the mineral wool will not be enough to achieve a comfortable thermal insulation. The combined method of warming is also popular, when a mineral wool is laid between the layers of polystyrene foam to eliminate the “cold bridges”.

Currently, there are several varieties of frame houses on Canadian technology. In such projects, there is a departure from the traditional "canons", in particular, the replacement of boards with a bar.

Such is, for example, frame-frame technology, which is widely spread, since it can be realized with one's own hands without involving a crane and other special equipment. In this case, the basis of the "skeleton carcass" is made of frames from a bar with a cross section of at least 50 by 150 mm. The choice of a specific thickness and width of the material is determined by the region of construction, as well as the characteristics of the insulating layer and the facade.

More expensive, but simple to build is the house on the frame-shield technology. Such structures are assembled from ready-made (manufactured in the factory) shields. Each site has its own set of panels - wall panels with various communications, door and window openings. These elements are rather bulky and heavy, they cannot be assembled by themselves, a crane is needed.

From the panels are also going to the so-called frame CIP - at home. At the heart of the panels - OSB sheets.The manufacturer alternately lays the sheet, adhesive layer and insulation (foam), resulting in a durable material with high thermal insulation properties. Visually, the CIP panels look like a sandwich - between the sheets of the RSD there is a foam, which is fixed by means of glue.

SIP-panels have a special design and connecting nodes, due to which it is possible both frame and frameless construction. In contrast to the panels produced at the factory, CIP-analogues have smaller sizes (usually 2.5 by 1.22 m) and weight (1 m2 of the wall hardly weighs more than 20 kg), which allows to mount them personally.

Stages of construction

Construction of a frame house using Canadian technology begins with the analysis of the soil (it should be carried out at different times of the year) and the selection of the optimal type of foundation. After that, an individual plan is created or a typical drawing is adapted, and then the necessary materials are calculated and purchased.

Among the most common foundations for this kind of construction - strip, pile, columnar or slab foundations. Provide additional strength to the concrete foundation,as well as improve the waterproofing allows the use of asbestos pipes. Under them, dig holes about a meter deep in 80 cm steps.

Further, pipes with a height of about 1.5 m are inserted into these holes. The diameter of the pipes is 20 cm, if the excavated hole has a larger diameter, the excess space is covered with earth after the installation of the pipes. Finally, when the latter are firmly in the ground, a concrete solution is poured inside.

To organize the floor in such a house, a bar with a cross section of 5 to 20 mm is used, under which the roofing felt is laid (ensures the moisture resistance of the floor). In the direction transverse to the timber, the boards of the sub-floor are laid. Next - a layer of insulation and a layer of boards for flooring. It is important to make sure that the floor is even, because the geometry of the whole house depends on it.

The construction of the walls begins with the organization of the bottom trim, after which the corner posts are set, then the intermediate posts, and then the top trim is made.

You can also assemble the frame on the ground, after which with the help of a crane should lift it to the base and fix. This method is more convenient, but it requires the presence of assistants and the involvement of construction equipment.

Wall panels are fixed on the finished frame (if necessary, they are insulated with mineral wool), the roof trussing system is organized (most often it is a double-slope or mansard roof), the roof sheathing is performed.

Despite the strength and resistance to mechanical damage to wall panels, experts advise to protect them with finishing materials from the outside. Siding panels with imitation of a natural surface (stone, boards) are most often used as a facade.

In order to improve the sound insulation of CIP panels, they are used to plasterboard plastering on both sides. To reduce the impact noise in the house will allow the use of carpet as a floor covering.

Such is the general principle of the erection of a "skeleton" by Canadian technology. Step-by-step instructions can be given only taking into account the design features of the building - the type of foundation, the number of floors of the object, the type of panels used.

Tips and tricks

The quality of frame houses depends largely on the quality and moisture content of wood. Traditionally, sawn timber from conifers is used, which is caused by the presence of resins in them, which increase the resistance to decay and provide antibacterial action.

Reviews and recommendations of experts suggest that the best will be frames made of pine, spruce and fir. Larch, although it belongs to the category of conifers, is used only for small connecting elements. This is due to the fact that its processing is more difficult; when nailing nails into larch boards, there is a high probability of their splitting and cracking. The material itself is characterized by a large number of knots.

Another important indicator is wood moisture. When drying, the material shrinks from 0.3 to 10% depending on how much of the wood is used for sawn timber.

It is best to acquire a fully dried tree, the humidity of which is in the range of 7-15%. Do not blindly trust the seller, it is better to measure the moisture indicators yourself using a special device.

If not dried wood is purchased, then it should immediately be sheathed by RSD from all sides. This will help prevent the frame from warping during the natural drying process.

Construction of a frame house can be carried out on an individually developed or finished project. The latter option will be cheaper, while today you can find a large number of diverse drawings.In other words, even choosing a typical project, you should not be afraid to build a monotonous and boring building. In addition, the appearance of such buildings is easy to change, choosing a particular lining.

When determining the area of the house, consider the number of tenants. As a rule, an average adult should occupy 20 m2 of usable space. For a family of 2-3 people, a building with an area of no more than 100 m2 is sufficient. This is the best option in terms of convenience and content.

For a larger family (out of 4-5 people) it is better to consider a two-storeyed frame house. As a rule, it is more economical to build a two-story house with a small base area than a single-floor object with the same total area. Increase the usable area without resorting to significant expenses, allows the arrangement in the house operated by the attic.

The size of the plot also plays a role in determining the area of the house. So, on 6 acres, a building with parameters 10x12 m is quite appropriate, however, a house with dimensions of 15x40 m will almost rest against a fence, which contradicts the requirements of SNiP.

Beautiful examples

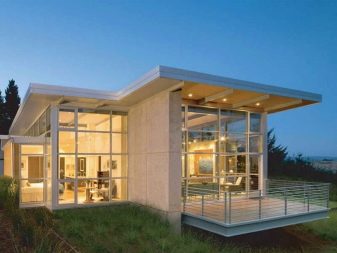

The frame house may have a different solution in terms of style.It all depends on the design features and the choice of finishing facade materials.

- As an example we will give a structure in the traditional classical style, sheathed with siding panels.

- Bright, spacious, with an abundance of windows, this small cottage, also erected according to Canadian technology in a modern style, turned out.

- By the way, modern exteriors (high-tech, loft) are successfully implemented in frame structures, since the latter are distinguished by brevity, the presence of columns. Glass walls, full-length windows, geometric simplicity of forms, naturalness of textures - all these features, characteristic of modern interiors, are easy to embody in terms of frame construction.

- Cozy wooden surfaces of CIP panels seem to be designed to be used for building houses in eco-style, rustic or rustic directions.

- The frame house does not necessarily have to have a large area and luxurious decoration. For connoisseurs of minimalism, and also as a modest country house, such an object in 2 floors or a compact one-storey version can be successful.

On how to build a frame-frame houses on the Canadian technology, see below in the video.