The process of warming a frame house foam

After the construction of the frame, it is time to insulate. By itself, the wooden skeleton serves as an excellent basis for filling the cells with insulating material, one of which is foam plastic. This material has excellent insulating properties and other characteristic advantages, including an affordable price.

First you need to decide what types of foam will be needed to warm the walls, floors and ceiling in the house, followed by the choice of brand material. After that, it is time for installation works, which are necessary to carry out, following the correct method in compliance with all rules and regulations.As a result of all the manipulations, the structure receives excellent thermal insulation and is ready for further finishing works.

Kinds

Polyfoam is not one material, but a whole class of them, the hallmark of which is a foam cellular structure. When insulating works in a frame house, the following types of foam can be used:

- PPT - polystyrene foam insulating plate or “ordinary polystyrene”;

- PSB-S - foam polystyrene suspended pressless self-extinguishing, non-flammable type of foam;

- penoplex - A modified version of polystyrene foam;

- penofol - rolled expanded polystyrene with foil substrate;

- liquid foam - carbamide-formaldehyde foam, great for blowing gaps, joints and other problem areas.

Each of these species has its own specifics, and its use is appropriate under certain conditions. Standard foam has several basic criteria, such as density and purpose: for walls, basement, foundation, and the like.

The density determines the basic parameters of the foam - thermal conductivity, the higher the density, the better the insulating properties and strength,which is in the same progressive relationship.

The main types of foam have a density of 10-35 kg / cu. m and the corresponding marking: PPT-20 (20 kg / cubic meter), PPT-35 (35 kg / cubic meter) and so on. And also this parameter determines the price and scope of the foam. For example, PPT-15 is relatively soft and cannot be used for floor insulation.

PPT-35 is considered universal, having the highest characteristics, because of which it can be applied everywhere, but its price is also the highest. It is inadvisable to use such a foam for internal wall insulation, where its strength will not bring any dividends, since it is simply not needed there. The dependence of strength on density is significantly higher than for thermal insulation properties. Often PPT-15 is used for roof / ceiling warming, PPT-25 for walls and other vertical surfaces, and PPT-35 for floors.

It is not difficult to lay insulation with your own hands if you follow the recommendations of experts. It is possible to insulate both mineral wool and penoplex. Each of them has its pros, as well as disadvantages and different reviews. Than to warm, you can choose yourself.

Phased insulation of the house

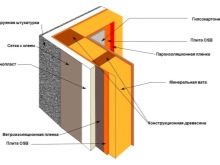

Vapor barrier

The foam does not allow steam, and, accordingly, does not allow moisture to evaporate through the facade of the building. To prevent its penetration into the frame of the building from the premises, it is necessary to produce a vapor barrier. For these purposes you will need the following materials:

- double-sided sealing adhesive tape;

- reinforced mesh or other material as a vapor barrier.

Works are performed in a specific order.

- At the time of work, the frame must be treated with protective impregnation, then access to it will be closed.

- Removes dust and dirt from the frame in the work area.

- A protective film is removed from the tape and is applied to all elements of the frame with which the vapor barrier will come into contact.

- The tape is removed from the second side of the protective film.

- The roll with vapor barrier rolls across the racks, consistently clinging to the tapes. The joints are taped, and the web rolls overlap by about 200 mm.

- After gluing the film, it is additionally fixed with a stapler at intervals of from 25 to 30 cm.

- In order to ensure further wall covering and protect the vapor barrier from damage, the slats are mounted on the frame. It does not matter, they will be attached immediately after the vapor barrier or immediately before finishing.

The technology of vapor barrier walls provides absolute protection against moisture penetration into the foam, but prevents its exit from the room. In this regard, a good exhaust ventilation must be installed in the house, otherwise mold and other problems cannot be avoided.

Thermal insulation and waterproofing walls

After the vapor barrier comes the turn of the wall insulation foam. For these purposes you will need the following materials:

- PPT or PSB-S plates 10 cm thick, suitable foam with a density of 15 kg / cu. m or higher;

- film with wind and hydro-protective properties;

- slats with a section of 20x30 mm;

- adhesive tape sealing;

- polyurethane foam.

Works are carried out as follows.

- The plates are stacked between the uprights of the frame, often the distance between them is initially laid down to the size of the plates - 50 cm. If the plate is unformatted, you will have to either cut or fill the gap with a cut piece of the plate of the appropriate width. For cutting foam it is better to use a small hacksaw or a mounting knife.

- The gaps between the frame and the plates are filled with foam.

- The second layer of plates is laid in such a way that the joints are not lined up with the first row, otherwise there will be cold bridges.The gaps are also filled with foam.

- The film for wind and waterproofing is mounted on the outside like a vapor barrier inside. The frame is glued over with a sealing tape, then a protective film is attached to it and subsequently fixed with a stapler.

- On top of the attached film to the frame are attached slats on the screws. The created gap is necessary for ventilation in order to remove moisture trapped under the facade cladding. When mounting rails, you need to use a level to maintain the correct vertical walls. If the frame was not erected perfectly, the slats provide an opportunity to fix it. The location of the slats is easily adjusted by placing plywood pieces under the desired end.

There is not much difference between that, first sheathe the frame from the inside, and then from the outside or, on the contrary, the sequence of these stages is left to the discretion.

Floor insulation

At this stage, you will need the following materials:

- PPT-35;

- vapor barrier film;

- sealing adhesive tape;

- polyurethane foam;

- penofol or other substrate.

Isolation occurs according to this plan:

- a paroisolating film with sizing of the joints is laid on the lags; the overlap of the canvases should be about 200 mm;

- Between the lag is laid PPT, and the gaps between them are filled with foam;

- a second layer of a vapor-insulating film is laid on top, the method of fastening is the same as that of the walls - on an adhesive tape, securing it with a stapler;

- above the substrate is laid to improve noise insulation.

Ceiling insulation

For these purposes you will need the following materials:

- PPT;

- vapor barrier film;

- sealing adhesive tape;

- nylon thread;

- nails.

Works are carried out in this order:

- vapor barrier is fixed on the ceiling beams and attic flooring by means of self-adhesive tape and stapler, like walls;

- in the lower part of the beams, nails are driven in with an interval of 20-30 cm, so that the caps protrude under the binding thread;

- the foam is inserted between the ceiling beams and fixed with a zigzag stretch of the nylon thread between the nails, with a tight fit of the plates, additional fixation can be avoided;

- The second layer of vapor barrier is fixed to the beams with a stapler.

Advantages and disadvantages

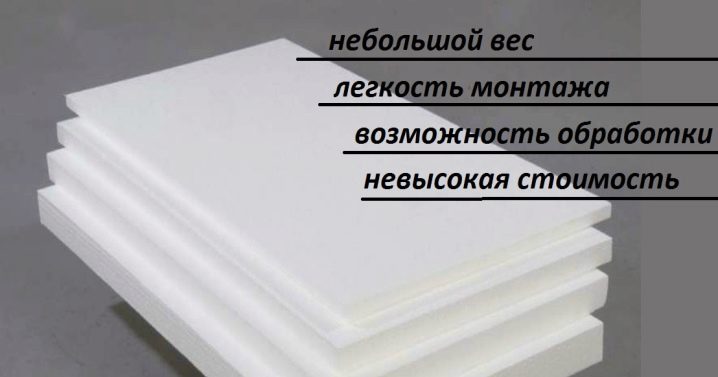

When using foam it is worth considering the specifics of this material on the basis of its strengths and weaknesses.

- Provides excellent thermal insulation - thermal conductivity is only 0.037-0.043 W / K * m.In winter, warmth does not come out of such a house, and coolness in summer, the hot street air again lingers outside. Polyfoam creates a thermos effect and allows saving both on heating and air conditioning.

- It has excellent moisture resistance and waterproofing, water absorption of foam sheet for 28 days under water is about 3%, resistance to water vapor diffusion - (p) for rigid foams from 20 to 100 units.

- High level of noise absorption.

- Low price, one of the most affordable materials for thermal insulation.

- When exposed to temperature conditions of the environment (temperatures of more than +100 C are terrible for foam plastic), the material practically does not change its volumes. The consequence of this is the lack of movement within the frame during heating of the foam, leading to deterioration of fixtures and surrounding materials. The plates sit in place, do not deteriorate, and therefore do not require replacement - repair, the operational life of the entire structure increases.

- Lack of toxic substances. The foam does not emit dangerous vapors, does not provoke allergies, does not emit unpleasant odors and is completely safe for health under normal conditions.

- FlammabilityStandard foam (PSB, PPT) has a degree of flammability of G3-G4, with the addition of flame retardants it decreases to G1 (low-flammable self-extinguishing substances) and is marked with the prefix C - PSB-S.

- Simple and easy installation. Works can be performed by one person, do not require physical strength and special skills, it is enough to carefully familiarize yourself with the technology.

The weak sides of the insulator are not many characteristics.

- Vapor tightness Moisture that gets into the walls, can not freely pass through the foam and accumulates, as a result of wooden frame damp and can rot. In houses with high humidity, exhaust ventilation is necessary.

- High flammability substandard PPT. A dishonest manufacturer may not add flame retardant components, with the result that the foam’s flammability will be at the level of G3-G4.

- Toxicity. Under normal conditions, the foam is safe, but when it melts and burns it emits toxic substances.

On how to warm the floor in a frame house foam, see below.