Frame houses: advantages and disadvantages of structures

Many dream of their own cozy home, but the exorbitant costs and duration of construction inspire no one. Experts recommend to look at the frame houses and choose a home to their liking.

Special features

The frame house is a pre-fabricated structure with interconnected bearing elements. In Scandinavia, according to the frame technology, private houses and more functional buildings of three or four floors are being built. The laws of Japan and a number of European countries provide for the construction of a seven-story frame houses. They built up and the American Wild West and Russian Siberia. Moreover, the Americans were attracted by the speed and budget of the building, while the Russians were attracted by high energy efficiency.

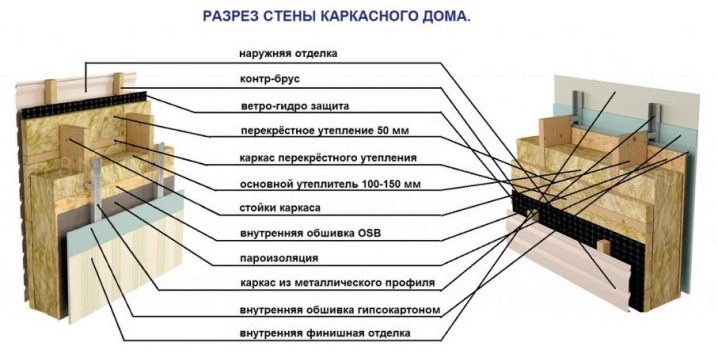

The frame of the house is a wooden or metal rack-and-beam construction, filled with insulating materials. Clay, saman and porous stone were replaced by modern thermal insulation, which makes the building even warmer. The small thickness of the walls of the building saves space, the uniform distribution of the load ensures the stability of the building, and the vibration in the form of a squeaky floor in the frame houses is completely absent. Frame walls have low thermal inertia - the ability to accumulate, and then gradually give off heat.

A significant part of the wall is made of insulation that does not accumulate heat, so the house heats up quickly and also cools quickly when the heating is turned off.

In the frame house daily temperature variations are more pronounced, while the walls themselves will not be damp or cold. Thermal inertia of frame structures increase due to the laying of foundation reinforced concrete slabs or finishing with two layers of gypsum plasterboard. A modern frame house is a multi-part construction responsive to the professional training of builders. Their inability or ignorance is immediately reflected in the quality of the building, giving rise to many myths.

- About fragility. In fact, the design lives from 30 to 100 years, and its durability depends on the quality of work and materials. Carefully dried wood and metal frame, treated with special compounds will last hundreds of years. As a heater, you should choose a hard mineral wool material that allows you to do without repair for more than 60 years.

- About the instability to cold. On the contrary, inside the walls between the racks of the frame there is a layer of insulation of 15–20 cm, which ensures high energy-saving quality of the walls. Often, frame houses are insulated outside with a 5 cm thick layer of extruded polystyrene foam, which protects the house from the cold, allowing it to be built in both the southern and northern regions.

- About uniformity. The principle of construction is not different: they put a frame, the walls are filled with insulation, protected by a vapor barrier film on the inside and a waterproofing super-diffusion membrane on the outside. Rigid sheeting and sheet material protect and frame, and insulation. Constructions differ in the material and method of construction, which makes each construction unique.

- About fragility. The strength of frame buildings are inferior to concrete or brick structures, but to destroy their walls is not so easy. Rigidity and stability are provided by the external lining of the OSB (oriented strand board), the multi-layer structure of which is stronger than a wooden solid. The walls of multi-layer insulation or of pre-fabricated panels differ in their high strength.

- About stuffiness. The design of a mechanical exhaust ventilation system is included in the construction plan of each house. The installed heat exchanger (heat exchanger) provides constant air circulation, and the opening windows allow to ventilate the room as needed.

- About non-ecological. Metal and wooden frames meet the requirements of environmental friendliness. Stone wool is an environmentally friendly material. Styrofoam has passed a series of laboratory tests and is recognized to be harmless to health. Insulating films are neutral, the environmental friendliness of GCR sheets is beyond doubt. At the slightest doubt, the quality of materials should be required from the sellers of the relevant certificates and confirmation of SES.

- About fire hazard. Frame houses are really not as fire-resistant as stone, so their walls and roof must be treated with refractory materials. Covering non-flammable sheets of DSP or gypsum plasterboard will protect from exposure to high temperatures and improve sound insulation. Fire resistance limit is 30–60 minutes (this information is reflected in the manufacturer’s certificate). When building a house should be borne in mind that the distance between the frame buildings is more than between stone.

- On the lack of individuality. Each company builds frame houses in accordance with the model projects included in the factory production program. If necessary, the project office can develop an individual project based on the wishes of the client.

- About unrepresentative view. For frame construction, you can recycle any project of a presentable brick or concrete house. Appearance depends on the plaster, paint, siding, block house and other finishing materials. For interior design, any design solution is suitable, and wide windows will help to create a feeling of spaciousness.

- About cheap appearance. The price of the house depends on its dimensions and building materials.The frame of laminated veneer lumber is more expensive than ordinary wood. The cost of basalt cotton wool exceeds the cost of expanded polystyrene. If additional warming is planned, the price for the house will increase significantly.

A smaller volume of walls and foundation carry frame houses to budget buildings.

Advantages and disadvantages

Prefab houses have gained popularity due to such advantages as:

- they are pre-fabricated, do not shrink, allow finishing work at any time of the year due to smooth surfaces and the absence of "wet" work;

- lightweight frame can be put on any ground, without equipping a massive foundation. If necessary, the latter is repaired without disassembling the house: it is enough to raise the frame structure with a jack and carry out the necessary work;

- The indisputable advantage is the minimum consumption of electricity in the cold season due to the low thermal conductivity of the walls and floors. If the power consumption exceeds 20 W / m² per month, there are gross errors in the wall insulation. The same effect is obtained when using low-quality building materials;

- Karkasniki draws attention to the optimal microclimate at home, the simplicity of the exterior, as well as the flexible adaptation of the internal layout to suit your needs.

However, in this barrel of honey there is a fly in the ointment. Frame houses have the following disadvantages:

- an attempt to save on building materials is hazardous to health: cheap OSB-plates contain phenol-formaldehyde resins that release formaldehyde into the living room. A similar substance contains cheap mineral and basalt wool, which is a source of carcinogenic dust. It is necessary to choose OSP-plates only with the first or zero class of emission, because they are safe for humans. Basalt or mineral wool based on non-combustible synthetic fibers will also not be harmful;

- The fire hazard of the building is eliminated with fireproof panels made of DSP or fire-resistant gypsum board. The expanded polystyrene chosen as a heater should belong to the fire-resistant class G1 or G2. The beams are built from glued laminated timber, which is not “afraid” of fire or treated with special means. In general, all this increases the fire resistance of the whole structure;

- construction of a frame house does not allow the work "by eye": you must be guided by accurate calculations, taking into account weather conditions of a particular region.This will not only get rid of unpleasant surprises, but also extend the life of the whole structure.

Frame houses are built according to a certain technology, each of which also has its pros and cons.

- Canadian technology panels or shields, so-called SIP panels, are used for cladding walls of frame-frame houses. The construction of this building does not require the use of technology, it is light, economical and does not shrink. Construction work lasts up to six months, and the constructed house is fireproof and resistant to diseases of tree species. Such structures are poorly ventilated, so you should consider in advance the air circulation system.

- German frame shield The technology is a mechanical assembly of panel panels. At the same time, heat and waterproofing, communications lines and windows are already installed in the factory. It is only necessary to properly assemble the arrived "designer". Frame-shield building budget, environmentally friendly and fire-resistant. Lifting equipment is required for its installation, and in case of improper connection of elements, a house with a low level of thermal protection will be obtained.

- Frame-monolithic technology involves the construction of a solid frame, consisting of reinforced concrete foundations, monolithic floors and columns. Monolithic carcasses are distinguished by fast construction, ease of installation, high heat and sound insulation. There are no serious flaws in the construction, and compliance with the calculations and installation rules will make it possible to put a house on the site that will please more than one generation.

- The so-called modular homesconsisting of elements that are connected without bolts. This construction with a wooden or metal frame can be easily assembled directly on the site. Construction work will be completed in record time, installation in seismic troubled areas is possible, and the building can be mounted even at low temperatures. The rapid pace of construction does not inspire confidence in many, therefore the majority of our fellow citizens prefer the usual fundamental structures.

- Log cabins frame houses are a mixture of German half-timbered houses and Canadian technology. To create load-bearing structures, rounded logs are used, and walls are filled with short logs.The advantages of log structures in the minimum cost of the foundation, low thermal conductivity, quick installation and waste-free production.

In this case, the log walls are not only subject to natural shrinkage, but also fungal diseases, therefore, they must be treated with antiseptic.

Materials

The key to a comfortable stay in a frame house is the use of high-quality materials at all stages of construction. An important point is the choice of insulation. So, for the walls of wooden frame houses, the thickness of which reaches 18-25 cm, basalt wool is laid as a heater. Indicators of houses with a metal frame are similar to the first option. For frame-shield buildings as a heater wall thickness of 12-25 cm is often used polystyrene foam. The frame of laminated veneer lumber is laid with several layers of any insulation, and the wall thickness reaches 35–40 cm.

The regulatory thickness of the insulation layer must be at least 15 cm.

It is worth considering in more detail what types of heaters correspond to this indicator and dwell on their features.

- Mineral or basalt wool represents the dense pressed plate which is put inside of a wall. Mineral wool is famous for compactness, lightness, durability and fire resistance. But choosing this material as a heater, you should take care of waterproofing walls, because it is “afraid” of water, significantly affecting its functionality.

- Polyfoam or polystyrene foam for a long time had no analogues in the frame construction: cheap lightweight sheets are so easy to cut and lay, and they do not absorb water. But because of its fragility, flammability and low noise insulation, foam plastic has been squeezed out by materials with better quality indicators.

- Extruded polystyrene foam It looks like a dense foam, so it is used as an additional insulation. It is used for thermal insulation of the foundation, basement of the building and the floor on the first floor, as well as laying the outer lining of houses to improve the energy efficiency of the house. High-quality, durable and expensive material is often used for buildings of premium class.

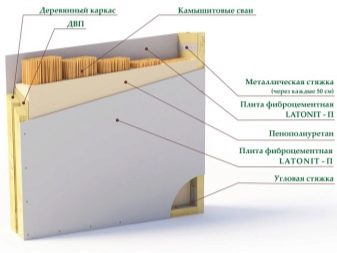

- Polyurethane foam (PUF) It is a sprayed insulation, equally suitable for walls and roofs.It is durable, water and fire resistant, withstands temperature extremes. Over time, the material "is aging", which significantly reduces its insulating properties, and low vapor permeability leads to the appearance of mold on the inner surface of the walls of the building.

- Ecowool 80% consists of cellulose, 12% - from boric acid, which protects against bacteria and fungus, and 8% - from sodium tetraborate, which reduces the level of flammability and flammability. This material is safe for human health, non-flammable, has high heat and sound insulation, resistant to rotting processes. Over time, ecowool decreases in volume, so this insulation is laid by 20–25% more than needed to prevent shrinkage.

- Light reed plates, made of compressed reeds, are low cost material with low thermal conductivity. It is suitable both as a filler for walls, and for insulating the interior of a house, as well as for floors and coverings. Reeds are "afraid" of rodents and are combustible material, therefore need to be treated with appropriate means.

- Gaining popularity reed polyurethane panels, combining the best properties of both materials. Reeds, filled with polyurethane foam, is so durable that it can be used in frameless construction.

These plates are 87% composed of natural reeds, protected by polyurethane foam from small pests.

Construction of carcasses is not complete without wooden boards: of them they collect vertical pillars and horizontal crossbars, partitions and floors, battens and the base of the roofs and much more. It is necessary to consider in more detail the features of this material.

- Coniferous and deciduous trees are used in construction. Pine and cedar, spruce and larch are easy to process, and the high resin content prevents the appearance of fungus. Boards made of beech, ash, linden, aspen or walnut are often used for interior decoration. They are denser than conifer boards, they are harder to dry, which affects the price of the material.

- For sawnwood there are certain quality requirements. They must be strong, durable, convenient and easy to use, have stable parameters, changing only within the established limits prescribed in GOST.

- In our country, all lumber is divided by grade.The first highest grade material is presented without knots and delays, suitable for the installation of load-bearing structures. Boards of the fourth grade are used as auxiliary materials, for example, for the device of formwork.

- Only dried boards are used for construction, because the use of raw materials leads to the formation of cracks and a decrease in strength. Artificially dried lumber can be purchased in specialized stores, but it can be dried naturally.

- To do this, the boards are laid in a pile under a canopy on stands at a distance of 40 cm from the ground. On top of each layer of the board, gaskets are laid approximately 40 mm thick for air circulation. The ends are covered with bitumen, linseed oil, paint or any other waterproof compound to prevent cracking. In this form, the board dries from four months to a year.

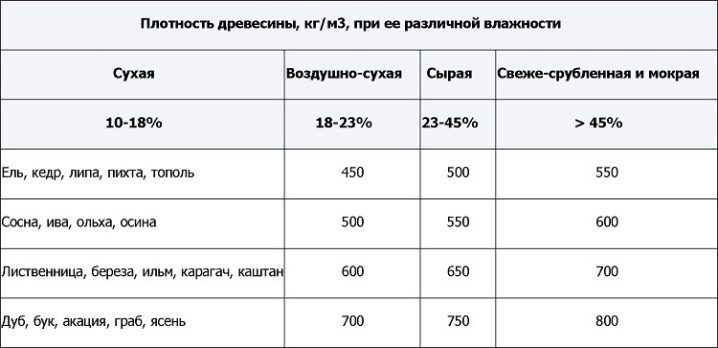

- It is important to determine whether the wood is dry or not before it is used in construction. So, light boards with fresh cuts indicate high humidity, and a dark shade indicates dryness of the material.

- To the touch dry boards should be with sharp splinters and low weight, and the chips should break. When tapping on a dry tree, you will hear a ringing knock.If there is any doubt about the dryness of the material, it is worth taking a piece of it, measure the density and look at the density table, which is characteristic of this breed.

In one building you can combine different wood species depending on the location.

- Ideal, though expensive option for the foundation of the house are considered boards of larch or oak. The budget strapping of pine or spruce boards will not yield to durability and reliability. In any case, the wood is treated with water-repellent, antiseptic and refractory agents.

- Compressive load bearing structures perfectly withstand pine and spruce. Boards are treated with an antifungal compound, and since no one sees the frame upon completion of construction work, it is permissible to choose a material with surface defects.

- For the interior walls any board of coniferous wood will be suitable. Coniferous boards are also used for the floor, but for ceilings it is better to choose oak, beech or walnut wood, as they will create beauty without additional finishing. The rafter system and the roof crate are created with the help of pine or spruce boards.

- Walnut, oak, maple, cherry, yew and many other deciduous trees are ideal for decorating walls. It is important that the surface of the cladding boards is free from damage and well polished. Fire-resistant or antifungal means decorative boards, as a rule, do not process so as not to spoil the natural pattern of the tree.

When building frame houses popular use of solid timber, which has no gaps and therefore does not shrink. When erecting frame walls, the timber is mounted vertically, therefore shrinkage runs horizontally, significantly reducing its deformation.

Separate elements of the skeleton carcass are connected with anchors, screws, bolts and nails. The latter have been significantly improved by anodizing, notching, longitudinal screw extraction, which added reliability to fasteners. And the emergence of automatic hammers with clips of nails made it convenient to work.

Reliable steel brackets are designed for mounting large items such as timber, logs or boards from 50 mm thick. The impact anchors are hammered in, the screw ones are held in the board by means of the blades in the form of a thread. The most common type of screw anchor is an inexpensive and reliable self-tapping screw.

The turbovint, which differs from its counterpart by a powerful central pin, is in demand, which not only increases reliability, but also expands the field of application. For through clamping fasteners, it is necessary to prepare a through hole in which a threaded rod or wooden dowel rod is inserted. The first one is fastened in such a way that it is held in a board due to the efforts created by it. The second is a smooth wooden pin used to connect the crown logs.

Projects

Do not immediately run to the store for building materials. First, you should think about how the house will be: large or small, with or without a garage, how many people will live in it and whether it is often planned to receive guests. Not only dimensions, but also the internal layout of the house depend on it. It should draw a project with the location of rooms and bathrooms, verandas and garages.

It is not easy to do this manually, as designing a house requires knowledge in the field of construction and engineering. Therefore, it is necessary to create a project in a special computer program that will allow not only to see first-hand the future construction, but also help to accurately calculate its dimensions.

It is worth looking at several options that will help design the frame house.

- One-storey house with an attic with a total area of 34.7 m². Downstairs there is a kitchen combined with a hallway, a room and a staircase leading to the second floor. The size of the house is 6x4 meters.

- Two-storey house with a total area of 72.7 m². On the ground floor they placed the living room, kitchen, hallway and pantry, which can be converted into a bathroom. On the second floor there is a walk-through room leading to the bedroom.

- A single-storey building with an attic with a total area of 68.51 m². On the ground floor there is a large and small room, a kitchen, a small entrance hall and a bathroom. In the large room put the stairs leading to the top. Half of the second floor is occupied by the attic, and the remaining half is the “second light” above the large room, emphasizing the lightness and airiness of the building. The size of the house is 9x6 m.

- The layout of a small one-story house with a total area of 16.95 m². It consists of a kitchen, a small corridor and one room. The size of the house is 5x4 m.

- Two-storey house with an attic with a total area of 87.14 m². On the first floor there are a couple of rooms, an entrance hall, a kitchen and a storage room, and the second floor is divided between an attic and a living room.

- Two-storey house with a total area of 84.96 m².On the ground floor they designed the living room and living room, the entrance hall, the kitchen and the bathroom. In the attic there is also a small hall and three rooms: one small and a bit more spacious.

- Two-storey house with a total area of 86.05 m². On the ground floor of the building there is a conveniently placed living room, kitchen, bathroom, as well as a spacious entrance hall with a staircase. You can climb the stairs to a wide corridor, on both sides of which there are two rooms.

At the design stage, you should determine the features of the area in which the building will be erected.

It is necessary to think about laying communications, find out how far or close the future house is from the gas pipeline and power lines, decide how the water supply system will be arranged. After drawing up the project, you should consult with experts. If necessary, make adjustments to the project, to assure him of the local authorities. And only after that you can start construction work.

Building

First of all, you need to prepare the site, clearing it from old buildings and garbage. It is necessary to clear the road for the car to ensure smooth delivery of building materials.It is recommended to think about where you can store building materials: if the plot has uneven terrain, then it is worthwhile to place them on a hill. After that, you can proceed to marking the site, marking the location of the walls with pegs and ropes stretched between them.

Then you should make sure that their length is correct, and all angles are located at 90 degrees.

The slightest deviations should be eliminated, as they distort the structure and incorrectly distribute the load, which reduces the strength and reliability of the structure. At this stage, pave, insulate and waterproof communication. It is necessary to designate all connections in order not to get confused during the subsequent installation. Now you can proceed to the construction of the foundation.

It is believed that the block or monolithic foundation is suitable for a frame-monolithic house without a basement, tape or reinforced concrete - for construction with a basement room.

Modular buildings erected on pile-screw or block, log houses - on the columnar foundations.

But this division is conditional, because for the skeleton carcass one can build any foundation, so long as it is large, level and solid.

To determine the construction of the foundation, you should consider the characteristics of each species.

- For tape foundation first prepare the trench 100-400 mm deep, poured there a layer of sand with a thickness of 100 mm, creating a sandy pillow, then laid metal reinforcement. After that, self-mixed concrete is poured into the trenches. The foundation should rise 100–300 mm above the earth's surface.

- Slab the foundation, which is built of concrete and reinforcement, is also called floating, because the house rises and falls with it during seasonal expansion of the soil. The slab is either minimally buried 100–200 mm into the ground, or it is poured concrete onto a gravel bed without digging. The water-resistant compound added to the concrete mix ensures the resistance of the concrete slab to groundwater and extends the life of the foundation. Reinforcing mesh provides additional strength plate.

- Pile screw the foundation is obtained by using asbestos pipes or prefabricated metal piles. For the first, they dig holes, install a pipe with metal fittings in them and fill it with concrete. Metal piles are simply screwed into the ground.

The next stage of construction is the installation of the grillage or the bottom trim of the frame. It is carried out with the help of durable wooden timber 150x150 mm, which is one of the bearing elements of the structure, which holds the entire structure. The corners are joined in a half-wood, when the thickness of the beam is cut in half, or in a semi-lap, when the beams are cut at an angle.

From above, the connection is secured by a plate or a metal bracket, the angle of the strapping and the foundation is connected by a metal anchor, and upon completion of the installation work the beam is treated with antiseptic agents. Vertical elements of the frame or rack put on the first row of timber and fasten with it. Begin installation from the corner and around the perimeter of the entire building, maintaining a certain step. From the racks depends on the reliability of the house, so you need to check their verticality with a plumb.

For reliability, install temporary diagonal struts.

Draft floor built of wood or concrete. Multi-layered concrete floor is poured over the ground: a thin layer of sand is poured, thermal insulation is made of adobe, expanded clay or penoplex. Then pour concrete, mixed with waterproofing additive.For the construction of a wooden floor on the bottom tie lay wooden logs. Bottom boards are nailed to them, on which insulation is laid.

The next step is the construction of walls, the frame of each of which is assembled separately. Top, bottom and vertical elements are assembled, lifted and put on the bottom strapping. At the same time, the wall with a length of six meters can actually be lifted up by three, and the walls of greater length are assembled from several frames connected by threaded joints at the joints. Some projects of frame houses include the presence of inclined elements or stitches that enhance the strength of the building.

As a rule, they are made from 50–150 mm or 50–100 mm planks.

During the assembly process, a bolt is fastened to the frame, which is a horizontal beam with a minimum thickness of 50 mm, attached near the boards of the top trim. The maximum load falls on the corners of the structure; therefore, two or three support boards are needed to assemble them. The turn of the upper beam has come: it will lie perfectly even if the level of the lower row and the vertical posts is maintained. It is fixed with metal corners and fixed with bolts.

Nails can also be used, but they must be included in the timber not less than 10 cm.

The beam for the ceiling beams is secured with corners, resting it on the upper binding structure. Apply more complex mounting options for ceiling beams with the help of brackets or when a special socket is prepared in the upper beam. If the project does not provide for the construction of the second floor, you can install a truss structure for the roof, to which the crate is attached. Then there is a warming of the roof and exterior walls. Insulation set vasopor (close to the racks), there should be no gaps between the plates, and if necessary, you should arrange a vapor barrier and windscreen with special films and membranes.

Insulate both internal and external walls.

The latter are designed so that between the wall and the membrane the thickness of the air gap is not less than 50 mm. Through it comes the moist air accumulated in the wall. The gap is equipped with wooden slats 50x50 mm wide. They are attached on top of the insulation, creating a wooden crate, and on top of it install slabs of external walls.

Assembly of internal walls is similar to external, only the inner walls are made of thinner boards, because their thickness should allow to mount both insulation and noise insulation material. After assembling the frame, you can proceed to the installation of doors and windows in the openings provided by the design scheme.

For the installation of the finished window, it is better to invite a specialist, but the doors really should be assembled from boards of 25–30 mm in thickness.

It is time for interior decoration. As a rule, the works start far from the exit of the room and spend them alternately in all rooms. First, put in order the ceiling, then you need to do the finishing of the walls. For her use sheets GCR or GVL with a high strength, flat surfaces which do not require additional processing. It is only necessary to putty the joints between them and glue the joints with paper tapes.

Wood-based OSB boards should be plastered and plastered. Then the surfaces should be primed under the appropriate finish: with glue for gluing wallpaper or with primer under the paint for painting. It remains only to paint the walls, stick wallpaper. Only after this is laminate, linoleum or planks laid on the floor.

Reviews

According to the owners, the very idea of such a construction attracted them with simplicity, budget and availability of materials. When they talked to the experts, it turned out that the light weight of the panels would not complicate the delivery of materials, the construction does not pollute everything around, and you can start it at any time of the year. And then the question was finally decided in favor of the frame structure.

People already living in finished houses are satisfied that the frame house can significantly save on heating. Virtually all sites carried electricity, allowing to warm the house. And for heating 10 m² only 1 kW is required. Energy-saving doors and windows significantly reduce heat loss, you only need to warm the air to ventilate the rooms, but this will amount to ten percent of the total heat loss.

Residents like the strength of a frame house and its ability to warm up quickly in the cold season. The last property allows you to comfortably spend the weekend at the cottage in the winter, turning off the heating on weekdays. In the cold period, the temperature inside falls only a few degrees, and in the warm season the house has a pleasant coolness.A lot of good words were said about the heat and sound insulation of the building, as well as about the air passing walls. Many are pleased that the frame houses with thin walls keep the heat no worse than brick buildings, while the thickness of the walls saves space, freeing up space.

However, the warmest reviews deserve homes built on Canadian or German technology. Houses of domestic producers often have to be ventilated, steps in the room are given with a roar, because of which the walls and floors are additionally covered with basalt insulation. Often the walls have to be strengthened before they hang shelves or paintings. But even such “imperfect” buildings found their buyers. Technologies for the production of frame houses are developing not only abroad, but also in Russia, becoming more and more perfect every year.

Tips

It is recommended to listen to the advice of experts to create a beautiful and durable construction of a frame house.

- You should not spare time for the development of the project, since it will allow you to avoid cost overruns and permanent repairs due to insufficient section of the beams.As well as the draft will allow to avoid the destruction of structural elements from improperly calculated loads or inappropriate fastening methods.

- All lumber, located at 25 cm from the ground, must undergo a preliminary antiseptic treatment.

- The “warm corner” of a frame house is assembled from three vertical boards, which are installed in mutually perpendicular planes. Warming of vertical walls is permissible only by rigid plates.

- Black screws are used only for fastening sheet material. Their use in the power frame is unacceptable, since they do not withstand the load and break. Power elements are fastened with galvanized nails, as well as chrome-plated or brass-plated screws with a diameter of 5 mm.

- It is necessary to observe the sequence of assembly: first you need to build a ceiling with floors, then assemble the walls and put them in a vertical position. In this case, a solid surface is created, on which it is safe to move. The ceilings are securely fixed, it is convenient to work with the material, and the slightest deviations from the project can be eliminated before the walls are erected.

- You should always rest on the beams on the girders of the bearing walls. The floor beam and strapping beam are fastened either with steel supports, or with the help of a backing support bar with nails breaking through. Steel supports of beams are equal in height to beams and are attached with nails.

- The optimal step of the beam floors is 30–40 cm, so that they do not bend under shock load. For flooring it is worth choosing sheet material 16 mm thick: if you glue it to the joists of the floors, this will significantly increase the bearing capacity of the building.

- Sheathing of the cladding joins only on the uprights and crossmembers, attaching them in a run-up, which improves the strength of the power frame. The outer lining strongly binds the upper and lower trim to the wall frame.

- The warmed cake of the frame house is laid with a continuous layer of vapor barrier, that is, the sheets are glued with an overlap and lay the entire protected circuit.

Beautiful examples

- The massive log walls, the snow-covered roof, the deliberately rough porch do not make a repulsive impression. On the contrary, the situation beckons to plunge into a winter fairy tale.

- Simple and concise: a small two-storey skeleton with an open porch for a pleasant stay and friendly conversations. Compact, nice, cozy building.

- A small frame building with a glazed veranda, on which it is so pleasant to while away the rainy days. An excellent choice for those who come to the country at any time of the year.

- Created by a frame-shield technology, a light, light house with a tiled roof and shutters on the windows combines the best traditions of modern and traditional buildings.

- A small bright house is an excellent solution for summer residents who pursue only practical goals. In the summer, in the fall, in the spring, comfortable living is ensured in their own home, and from the hassle of the garden and garden it is so nice to rest on a small veranda.

- Frame construction with a flat roof - it is unusual, stylish, modern. The spacious veranda is simply created for relaxation, and the wide windows allow you to enjoy a luxurious view even in bad weather.

How to build a frame house with your own hands, you can find out by watching the video a little lower.