Finnish single-storey frame houses: characteristics and description of structures

Many people associate the phrase “Finnish house” with a warm, cozy wooden structure. If we talk about frame houses on the Finnish technology, then this is true. What features of this technology, its advantages and disadvantages, will be described in detail in this article.

Special features

All frame houses are united by the fact that basically they have a frame on which plates or more enlarged elements are hung. Due to this feature, the frame elements of the skeletons are the columns of the frame, and not the walls. This allows you to reduce their thickness, which means - to increase the internal usable area of the object.

The frame house can be built according to different technologies, the most famous are Canadian and Finnish.From the names it is clear that they originated in America and Finland.

Finnish houses are built from large-sized shields. Such a product is a "pie" of the outer and inner layers - with a vapor barrier film laid between them and a layer of insulation. Sometimes the outer layer is covered with a finishing material, and the inner one has a rough finish. Such boards or slabs are assembled in the factory, after which they are delivered to the construction site and combined into a single whole (according to the principle of the designer).

The basis of the shield is natural wood, which ensures its good (even without insulation) thermal insulation characteristics and high vapor permeability. Thanks to the production technology (steam treatment), impregnation with antiseptics and antipyrine panels are biostable and have good fire resistance (correspond to natural wood impregnated with antipyrine).

Mineral wool is commonly used as insulation, so you can talk about a fairly high environmental safety, which distinguishes Scandinavian (Finnish) houses.

Argued that such designs are not warm enough. However, this is not true, since the climate in Finland is close to the conditions of the Russian climate, therefore, according to the Finnish technology, houses are also considered adapted to domestic weather conditions.

In addition, it is one-storey and two-storey Finnish houses that have the maximum thermal efficiency compared to other frame technologies.

Houses of this type have less weight (compared to the usual buildings of the block, brick or wood), so the installation of a lightweight foundation is enough for them. This (and a number of other factors) can significantly reduce the cost of the Finnish home. If we compare it with a brick building or a block house, it can be noted that this option will be 15-20% cheaper.

At the same time, in terms of their performance characteristics, the skeleton carcass is not inferior to the majority of “classic” buildings. However, remember that its service life is only 50-75 years. Then you can use the house, of course, but you have to do major repairs.

High speed of installation and the ability to work (except for the arrangement of concrete) year-round are also obvious advantages of technology.

Projects

“Karkasniki” according to the Finnish technology is always the home of a considerable degree of readiness, consisting of factory-made shields and structural elements.

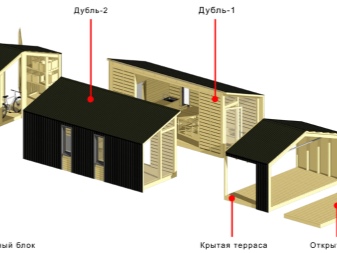

Such modular homes come in several types:

- Block-modular. They are assembled from ready-made, factory-made panels. The installation process resembles the assembly of toy houses from cubes. In Russia, this method is used infrequently, due to the large weight of the modules (additional costs for transportation and increasing the labor intensity of the installation) and the uniformity of the building itself and interior decoration.

- High readiness wall houses are frames for mounting wall panels. Such a framework has an inner and outer side, a layer of insulation is laid inside, a vapor barrier is provided. Usually, the front side is sheathed with facade material, the inner one can sometimes have a rough finish.

Panels are deaf, as well as having window and door openings. Modules are tightened around the frame and fixed. Then from pre-cut materials (the same that are used to create the module) are collected elements of overlap, roof frame, and so on.The width of the modules is usually 60-80 cm, the length corresponds to the height of the floor, the thickness depends on the thickness of the layers that make up the modular "cake". The most famous manufacturer of such wall kits in the domestic market is Finndomo.

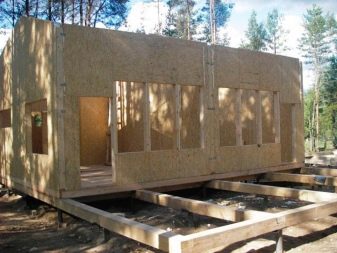

- Pre-cut wall panels (pre-sliced material). Mounting technology is close to Canadian technology (using CIP panels). First, a project is created, and then modular elements are made specifically for it. However, at the factories they do not unite into a monolithic “pie”, but are cut to the desired size, numbered and delivered in a folded form to the construction site.

Fastening of external and internal panels, laying of vapor-permeable materials and heaters, facade cladding are made directly on the site - by a team of builders or the owner of the house (if it comes to installation with his own hands).

This technology involves the use of much more dimensional boards (when compared with the use of CIP panels). Among the reputable developers working on this technology, we can distinguish a group of companies called Kastelli.

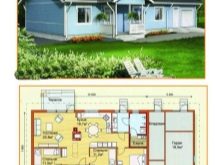

The design of the house according to the Finnish technology is made to order, or standard drawings are used. The first method will allow you to create an object that best meets the user's expectations, but it will cost more.

Even choosing a typical project, you can be sure that the desired design will be found - today there are many offers from developers. The most popular designs for permanent residence (year-round living) are single-storey houses with an attic and a single or gable roof. They can be equipped with a sauna, garage, open terrace or carport.

The construction of a two-story analog is also popular, but you will have to make a more solid foundation. In combination with the increased amount of materials, this leads to an increase in the cost of the project.

The advantage of the construction in one floor with a mansard is that it will “fit” even in a small area. Thanks to the attic and the proper organization of the internal space, it is possible to obtain almost the same area as in the construction of a house on 2 floors without an attic.

When ordering a project, you should remember thatthat due to the large size of the modules it will be impossible to rebuild the house or change its layout (as opposed, for example, to objects created using Canadian technology).

Device

The foundation of the "skeleton", built on the classical Finnish technology, can be performed on one of these technologies:

- Insulated Swedish stove. It is intended to create a bowl of high-strength polystyrene, into which a thin concrete slab is poured. For greater reliability, reinforcement ribs are provided in the latter.

As a result of such actions, it is possible to warm the foundation already at the stage of its creation. In addition, all communications (for example, necessary for organizing a heated floor) can be immediately laid in the stove.

An important point: this type of installation is not suitable for areas with a slope. In addition, when using this technology will have to put up with a low (no more than 30 cm) base.

- Shallow-footing foundation. The strip foundation, which is classic for domestic construction, can be not deepened. The essence of the method is reduced to pouring the base, which is then sprinkled with soil (for which the technology is sometimes called “floors on the ground”), is insulated and reinforced with a coupler. The last thing you can do is lay the communications system.As a rule, the insulation and reinforcement of the floor are not carried out immediately, but after working with the walls and roof, that is, in an almost finished house.

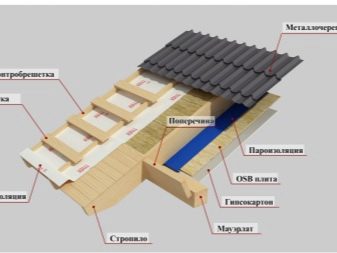

A feature of the roofing system is the preservation of the ventilation gap in it. Roof is a multi-layer "pie" - regardless of whether it will be cold or with an attic organized inside. It includes insulation, mounted on the frame, waterproofing layer and counter-sheathing, which is printed roofing. There are various options (shingles, folded roofing are widespread) - except for ondulin.

The wooden frame should be assembled only from well-dried wood. There are no strict regulations regarding the materials used. Glued laminated timber or LVL (laminated veneer lumber) is usually used.

The knot of the walls falls on the junction points of the side and front walls, the floor and the walls, boom. It is these zones that need additional reinforcement ribs.

If we compare it with the American technology, where OSB-plates are usually used for plating, it can be noted that the Finnish method involves the use of other materials that are distinguished by better vapor barrier performance.

The most common are the following types of skin:

- soft fibreboard (MDVP) with high thermal insulation properties (in their heat losses correspond to mineral wool), providing noise insulation and wind protection;

- facade drywall (not very popular in Russia);

- cladding plate materials of high rigidity (eg, plywood) only the corners of the building.

Finishing the facade of a frame house according to the Finnish technology in 90% of cases involves the use of wood. The rest (about 8%) are plastered surfaces. Siding panels that are very popular in America are rarely used by Finns.

Wooden facades are almost always painted with a covering (opaque) paint. It is characterized by durability (it is necessary to renew a layer of paint on traditional Finnish “carcasses” only once in 10–15 years) thanks to a special production technology.

The pile of the front board is specially lifted. It looks “shaggy”, which contributes to a better absorption of paint and a thicker layer.

Since opaque compositions are used for painting, the boards are nailed to the facade is not hidden.This simplifies the process of plating and allows for a stronger fixation of the boards.

Construction technology

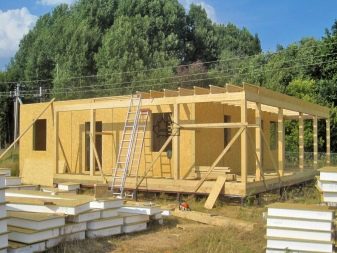

Houses according to the Finnish technology are assembled on the basis of the constructor principle, therefore, if there are even small skills in the field of construction, it is quite possible to assemble the house yourself However, it should be borne in mind that the plates are quite heavy, so you can't do without helpers, and in some cases you will need the services of a crane operator.

Step-by-step instructions in general form as follows:

- foundation organization;

- laying of timber and installation of the lower trim;

- erection of the frame, fixing panels;

- device truss system;

- roof insulation;

- laying roofing;

- creating a top trim;

- insulation of the facade (if necessary), internal heat insulation;

- wall cladding.

However, this instruction may undergo significant changes (depending on the type of panels used). If, for example, house constructions of a high degree of readiness are taken, then they usually do not need additional warming and exterior decoration.

The pre-cut installation will be completely different, since each layer of the wall “cake” is placed manually - directly on the construction site.A mineral wool layer can be installed in the wall gap or ecowool can be poured. It also causes differences in the assembly process.

Prefabricated houses (like any other) are built only after the preparation of project documentation and approval of it in specialized bodies.

The drafting of the project should be preceded by geological surveys - observation of the soil and its analysis in different time seasons. Focusing on the results of the analysis, choose the appropriate type of foundation.

At laying of a bar and installation of a framework wooden logs are used. They must be pre-treated with antiseptics and flame retardants. The feature of the frame house according to the Finnish technology is the laying of the frame beam in the grooves, as well as its additional fixation with nails or screws. The grooves also have wall structures; after lifting, they are joined to the frame grooves, which ensures reliability and tightness of the house.

Tips

Often on the Internet you can see negative reviews on the thermal efficiency and sound insulation of Finnish houses. The situation when the thermal efficiency and ability to soundproof panels leave much to be desired is quite possible.It all depends on the type and thickness of the frame, the correct installation of insulation and vapor insulating films. The performance characteristics of the house are largely dependent on the professionalism and integrity of the developer. Do not trust the creation of the project and its implementation of little-known firms.

To get a favorable microclimate in the room, it is necessary to think over and organize the ventilation system. By the way, the Finns do not use expensive membranes for vapor barrier, costing standard film thickness of 200 microns.

Choosing between the frame of the boards and timber, it is worth giving preference to the second, because it is more durable. The pledge of quality construction - compliance with the technological principles of production and installation. That is why it is so important to choose dried and specially treated wooden material.

Communication wiring should be defined at the design stage. Communications themselves are laid in the assembled house, before the internal insulation.

To protect external walls from blowing Experts recommend the use of heat-insulating wind-proof plates. They fit better to the surface, which prevents the formation of gaps (when compared with films and membranes). In addition, the plates better tolerate changes in temperature and humidity.

Beautiful examples

The peculiarity of true Finnish houses is their organic nature: they fit into the surrounding nature, so they look harmonious and very comfortable. To achieve this, the simplicity of forms, the use of natural finishing materials, the lack of pretentiousness.

A special feature of the Finnish house is the presence of a terrace in it. This may be a small area under a canopy or quite a considerable space, including the one located on the second floor.

The Finnish love for the attic is also widely known. In most cases, houses are built on the same floor, but always with an attic room.

Traditionally used single or dual roof. However, there is also a roof of complex shape. As a rule, it combines a house and a lot of outbuildings.

As a country house or a seasonal building, an attractive variant of a frame triangular house.It is quite natural that, with appropriate thermal insulation, such a structure can be a place for year-round living, but for the residents of Russia this is still too brave an option.

Finnish houses look harmoniously, being made in the "village" styles: rustic, country. However, with the right choice of the house structure and finishing materials, it is quite easy to give the building a classic or modern look.

For information on how the Finns build "skeletons", see the next video.