How to insulate the floor of a frame house with expanded clay?

A very important component of quality repair is floor insulation. The question of which material is better to use for this is one of the main ones, because its microclimate largely depends on the insulation of a house. Today, the construction market offers a variety of solutions, but for many decades, expanded clay is in demand.

Special features

Warming of the floor with expanded clay corresponds to the existing GOST.

This coating has several characteristic features that distinguish it from other types of insulation and increase the attractiveness in the eyes of consumers.

- The material is made from natural raw materials: clay and shale rock under the influence of high temperature. This leads to its environmental friendliness and safe use in residential premises.

- Expanded clay is presented in the form of granules of a rounded shape, which are the result of rotational movements during heat treatment in a cylindrical furnace.

- It has a low thermal conductivity, thanks to which it reliably retains heat in the house, preventing the external cold from penetrating inside the premises.

- Excellent noise reduction creates good sound insulation.

- Frost resistance of raw materials and resistance to temperature fluctuations.

- Flammability - expanded clay does not support combustion, inhibits the spread of flame in the event of a fire.

- Lightness of the material and its round shape. This gives additional advantages when installing insulation.

- Low cost of claydite itself and work associated with its use.

Despite the large number of advantages, expanded clay has disadvantages:

- low resistance to moisture - granules absorb water, after which the material increases in size, and its insulating properties deteriorate, which significantly limits the scope of use of the coating;

- porosity of the material, which leads to its fragility and fragility - the granules must be laid with great care, otherwise their performance will be significantly reduced;

- for high-quality insulation requires a fairly thick layer of expanded clay, so it is not used in rooms with low ceilings, as this leads to raising the floor by 15-20 cm.

There are quite a few options for using expanded clay.

- Can be applied under the cement screed. The porous structure causes high thermal insulation, so clay is suitable for insulating wooden and stone houses, and is also used for balconies and loggias.

- Expanded clay is often used to strengthen the foundation and decorate the basement in order to qualitatively insulate the first floor of a residential building and build a blind area around the perimeter of the building.

- With the help of expanded clay fractions, it is possible to reliably insulate the floors of buildings and chimneys.

- For the arrangement of the cushion for the subfloor, clay raw materials are also often used.

- Communication pipes are often insulated with expanded clay material.

- It is widely used in landscape design for the decoration of garden paths, lawns and rabatok.

Depending on the size of expanded clay granules, the following varieties are distinguished:

- the material of the fines fraction is expanded clay sand;

- material of middle fraction - expanded clay crushed stone;

- material of a large fraction - expanded clay gravel.

The production technology of all these options is the same, but each has its own purpose.

So, sand is produced by grinding larger raw materials, while the particle size is 1-5 mm. This type of expanded clay is used to strengthen the cement slurry, as well as mixed with rubble and gravel to fill the voids.

Claydite crushed stone is more angular, it is devoid of a characteristic rounded shape, and in general, there is no crushed stone of any particular shape and size, it is rather something between sand and gravel.

Ceramsite crushed stone and gravel is most often used for high-quality surface fillings.

Professional builders recommend using as a heat-insulating material a mixture of all fractions, as this will ensure the most complete filling of voids and the overall quality of the work carried out.

Scheme

There are three different methods for using expanded clay.

Dry way

This option is optimal for a private wooden and frame house.At the same time, expanded clay sand mixes with gravel and is tightly poured into the space between the lags. Due to the fact that the insulation material includes materials of different fractions, the voids are filled as closely as possible., and completely eliminated the appearance of gaps. This generally creates a reliable and high-quality thermal insulation coating, which, moreover, can be built fairly quickly and without the involvement of specialists.

Wet way

This option is a coupler of three basic components. At the same time, sand is mixed with cement and expanded clay in the proportion of 2/1/3, then mixed with water and poured over the floor. Due to the presence of porous granules in the solution, the thermal insulation of such a coating will significantly increase.

This technology is most often used in garages, summer houses and other outbuildings. This method is more expensive and time consuming compared to dry.

Combined

In this case, small dry granules are scattered on the treated surface and poured on top with cement mortar. In this case, the coating is quite durable, and the heat insulation capacity is high.

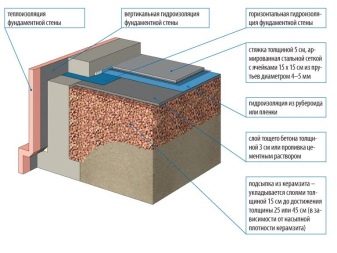

Regardless of the technology used,the floor is first leveled and covered with a layer of waterproofing material, as a rule, roofing material or polyethylene is used for this, and only after that the expanded clay is poured. The thickness of the insulation layer directly depends on the floor construction and the peculiarities of the foundation, everything is simple here - the thicker the layer, the better the insulation.

Installation

Covering the floor with expanded clay does not require much effort and time, but first you need to correctly make all the necessary calculations and prepare the base to equip the future "pie".

First of all, it is important to calculate the pressure on the surface, since the main load is on the floor.

To do this, you should determine the thickness of the backfill, in order to further develop not only a durable and practical, but also high-quality coating.

Before starting work, all existing cracks and chips in the old floor should be repaired, and then a layer of waterproofing material should be applied, as a rule, roofing material or plastic film is used for this. It is very important that the coating was cross, that is, its sections were overlapped, and also went to the walls at least 10 cm above the level of the future fill. Upon completion of the installation work, all surplus can be quite quickly removed.

These works take quite a bit of time, and after they are finished, you can proceed directly to filling the expanded clay.

The technology of work depends on the type of floor construction. Let us dwell on each of the options in more detail.

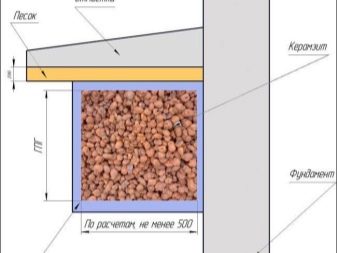

On the ground

Paul on the ground do in garages and sheds. If all the work done correctly, then in winter there will not be too frosty.

In order to cover the claydite on the ground, first you need to remove the top fertile layer of soil, level the area and tamp carefully. Then pour a mixture of sand and rubble onto the compacted ground, thus pre-leveling the surface.

To protect the claydite from groundwater, a layer of waterproofing is laid, and only then the claydite is put to sleep. It is very important that the entire surface is the same in height. At the finishing stage, the top layer is impregnated with cement mortar, which gives the insulation the desired fixation.

The screed on top is covered with vapor insulating material, and the work is completed by applying a reinforced cement screed.

After the coating is dry, if desired, you can lay a wooden floor or lay out tiles.

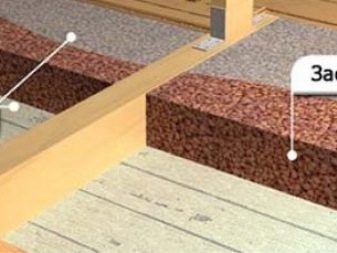

By lag

When using claydite as a heater, logs perform several functions at once. Firstly, they help to level the backfill, and secondly, they are used as the basis for the subfloor.

This method is used for insulation of concrete surfaces. First you need to completely clear the area of application, and to eliminate all the deformations and cracks of the coating, the lags themselves must be treated with fungicides. Then, with the help of their corners, they are attached to the base so that the upper faces of the guides extend into a single horizontal plane.

Usually, roll coverings or films are used as a waterproofing material, but bitumen mastics, polymer blends or rubber hydro-barriers can be laid, and the base itself, as well as logs, and part of the wall around the perimeter are usually treated.

If mastics are used, then to begin with, the base is primed; if a film is used, it is attached to the bars with a construction stapler.

Expanded clay is poured into the sinuses so that there is no empty space left, otherwise the insulating properties of such a coating will be significantly reduced.

At the final stage, everything is covered with a vapor barrier material, and a rough floor is formed.

On the balcony and loggia

At its core, the balcony is a protruding slab of reinforced concrete, therefore, it is rather uncomfortable to stand on it, even in the summer heat, so many apartment owners decide on the need to insulate their balconies and loggias.

Such a base is not necessary to align, the only thing you should pay attention to is that the surface should not be inclined.For this purpose, beacon rails are fastened over the entire area, which are fixed with plaster solution. The smaller the step between the lighthouses, the easier it will be to work further, since it is for them that they equal the height of the claydite layer.

The finished pillow is poured with cement and a screed is applied.

Tips

Expanded clay as a heater is valuable because it allows you to equip reliable and effective thermal insulation without hitting the budget. However, to improve the quality of the coating, it is necessary to adhere to several recommendations:

- to achieve the maximum warming effect, bulk material is used separately as an independent coating without mixing with cement mortar;

- the thickness of the backfill must first be calculated taking into account the permissible load and the strength of the foundation, especially if the house is erected on screw piles;

- any exposed beacons must be fixed with alabaster compositions - they tend to harden very quickly, which significantly reduces the time of work and improves their quality;

- To preserve the integrity of the coating and reduce the risk of deformation, the clayite layer makes sense to additionally reinforce with a special metal mesh

- to ensure maximum adhesion of the granules with each other, it is necessary to mix large granules with small ones;

- Despite the fact that you can walk on the floor after only a few days, its greatest strength and fixation will be achievable only after four weeks, therefore, if possible, restrict movement on the newly installed floor during the first month.

All these recommendations are quite simple in execution, and, not least, any thermal insulation work with expanded clay can be carried out independently with your own hands, even alone by a person who does not have any building skills.

You will learn more about how to warm the floor of a frame house with expanded clay, from the following video.