Features of the device and manufacture of the framework for bored piles

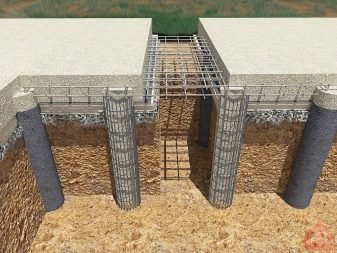

Bored piles today have become popular both in the construction of private houses, and for the foundation of multi-storey buildings and structures. Due to the features of the device and the manufacture of the frame, they have high performance.

Types and device frameworks

The basis of the bored pile is a concrete body and a skeleton of reinforcing bars. The main function of the frame is to ensure a high level of reliability of the foundation of the building, resistance to the effects of mechanical type. The choice of the required type of reinforcement cage depends on the conditions of the construction site and its type.

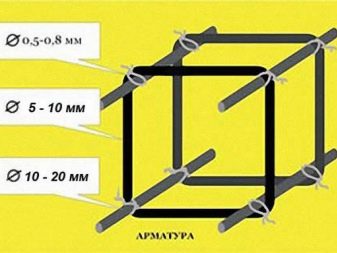

Construction fittings and wire - its main components. The types of rolled products used in the manufacture of reinforcement cages are varied: corrugated, smooth, hardened by stretching and exposure to temperatures, produced by the cold or hot method.For industrial production, raw materials are taken of the highest quality, since the strength of the concrete base depends on it. The diameter of the blanks can be any, depending on the required parameters of durability and reliability of the future structure.

Armored frames are of two types:

- spatial (volumetric);

- flat.

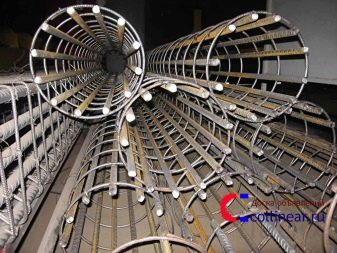

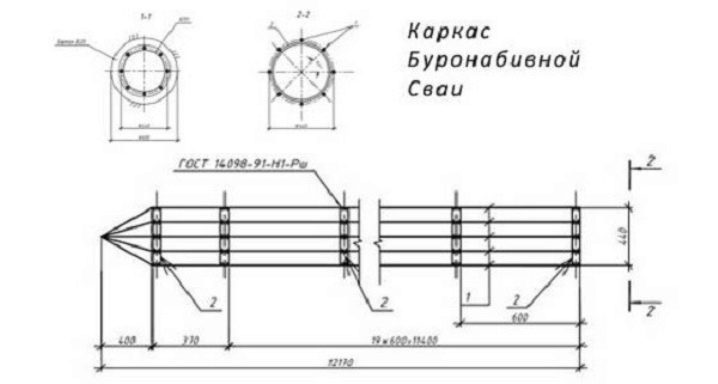

Volumetric frameworks are basically the construction of a round or square type of longitudinal reinforcing bars. In the round frame around these rods, the armature is mounted in a spiral. Between themselves, the longitudinal and spiral rods are tied with knitting wire or welded. Volumetric skeletons of a square type consist of gratings that are interconnected by reinforcing bars. The rods are attached to the plane of the prepared grid at a right angle.

The flat reinforced cage is a system of transverse and longitudinal metal rods. According to construction standards, rods should be interconnected by means of any kind of other rods: transverse, oblique, continuous type. Flat frames can be used as a finished component of construction, and blanks for further stages of work.This may be an assembly in bulk frameworks, bending, cutting elements, cutting.

A mandatory element of the structure of the reinforcement cage is release. This is the end of the base longitudinal rod that passes through the entire structure. Reinforcement takes its origin in the concrete body, and the last overlap of the building ends. This ensures the continuity of the metal rod.

Regulatory requirements

In the manufacture of reinforcement cages, it is recommended to focus on SNiPs, GOSTs and SP. The information will be useful to those who wish to work on laying the pile foundation were performed at a high level.

In accordance with the SNiP, the reinforcement cage should consist of six rods with a minimum diameter of 18 mm. Longitudinal reinforcing bars should be located along the entire length of the pile circumference evenly. The smallest allowable distance between them is 40 mm. The material is steel grade A400. In addition, plastic clamps from a pipe with a diameter of 90 mm and a length of 70 mm are required for the frame. Such rules are mandatory for the construction of large buildings and structures.

With the construction of the foundation of private construction requirements easier.The diameter of the reinforcement should be around 10-12 mm, but not more than 30 mm, and the number of rods should be from 4 to 6 pieces.

It should be noted that according to the standards, installation of bored piles in the winter season on flooded soils is possible at temperatures above -10 ° C. In a situation where the temperature regime is below the required mark, the work is possible only after a decision has been made on the use of assistive technologies.

Necessary tools and materials

Reinforced frames can be manufactured at industrial enterprises or directly at the construction sites themselves. Therefore, it is possible to assemble a design of the required shape according to individual sizes; you can also order a frame with standard characteristics at the factory.

For self-production of armo carcass, you need an angle grinder (Bulgarian) and a welding machine. If necessary, welding can be replaced by binding wire. And also need a tape measure, construction marker, anti-corrosion primer and paint brush. The raw material for the frame will be rods of reinforcement of different diameters.

Payment

As mentioned above, to create a reinforcement cage, we need precise parameters and characteristics of the future construction. First you need to decide on the choice of the foundation.If it is determined, the required number of rods and wire for bonding is calculated.

The key measuring value of the strength of the armo carcass is the diameter of the rods. The bigger it is, the stronger the design. To determine the desired thickness, information is needed on the type of soil of the construction site and the mass of the structure.

Required data when calculating reinforcement cages:

- pile diameter;

- pile length;

- distance between supports;

- the length of the reinforcement release;

- perimeter construction site.

For example, in construction it is planned to use piles with a diameter of 200 mm and a length of 2 m. The distance between the supports is 2 m. Reinforcement will be performed with three bars of ribbed and two smooth reinforcement. Reinforcement will be 300 mm. The base perimeter is 24 m.

To begin with, it is necessary to calculate the amount of reinforcement required, taking into account the perimeter of the construction site and the distance between the foundation supports:

24/2 = 12 pcs.

Then the required number of ribbed reinforcement is calculated for one pile:

(2 + 0.3) x3 = 6.9 m.

Then all the piles will need:

12x6.9 = 82.8 m (rounded up to 83 m).

Next, the calculation is made of the number of smooth reinforcement bent in an arc.

The circumference will be as follows:

3.14 x0.2 = 0.628 m.

One pile will require two such arcs.

Therefore, one pile of smooth reinforcement will leave:

2x0,628 = 1.256 m.

The total length of the required smooth reinforcement will be:

12x1.256 = 15.072 m (rounded to 16 m)

Thus, the creation of the reinforcement cage will require 83 meters of ribbed and 16 meters of smooth reinforcement.

Correct calculations are the most important factor influencing the manufacture of a sturdy and sturdy frame structure. Inaccuracies can weaken the foundation, as a result of which the structure may collapse.

Fabrication and installation

When all calculations are made, the process of creating a reinforcement structure begins. At the time of manufacture it is necessary to have a reinforcement scheme nearby. This will reduce all possible errors when working to a minimum and facilitate the assembly process.

For bored piles, the reinforcement cage design may be square, triangular or rounded.

All work on the manufacture and installation of armokarkas carried out directly at the construction site of the future structure.

The procedure for the assembly of the frame can be divided into several stages:

- cutting existing reinforcement into segments according to the calculations;

- preparation of cross bars for welding - bending, shaping an arc or cutting into 3-4 parts;

- metal construction;

- applying a special primer.

The process of assembling a square-shaped reinforcement cage is as follows:

- two vertically-longitudinal rods are connected in parallel in the center, top and bottom with the help of horizontally transverse bridges;

- The remaining two rods are welded the same way;

- blanks are fastened to each other.

At the end of the production of armo frame, it is installed in the well.

This technology looks like this:

- after drilling is completed, its bottom is laid with roofing felt or geotextile;

- the filling is made of crushed stone with a height of 10 cm, while crushed stone is used only for small fractions;

- the ruberoid is twisted in the form of a pipe, fixed with scotch tape and lowered into the well, the height of the ruberoid cylinder must be equal to the length of the reinforcement cage;

- metal construction is placed inside the existing formwork;

- a mixture of concrete is poured into the well, and in order to remove excess air from the mixture, the concrete is whipped with a rod.

The diameter of the reinforcement cage to be installed should be 0.14 cm smaller than the diameter of the borehole. Fulfillment of this condition will exclude the possibility of foundation jamming.To preserve the protective concrete layer, the frame must have clamps on the outside.

Merits

Reinforcement of bored piles is necessary to increase the bearing capacity, since concrete takes upon itself all the compressive load, and reinforcement - the tensile load. When using this method of installation of the foundation significantly reduces the dynamic load on the soil.

The advantages of using metal frames for bored piles when constructing the foundation are as follows:

- short installation time;

- reduction of the volume of production work;

- increase productivity;

- increasing the profitability of production;

- the ability to install the foundation on various types of soil, including on the complicated.

Such a pile foundation is often used in those building areas where the use of other technologies to lay the foundation is impossible due to constrained environmental conditions. The lifetime of the foundation using reinforcing cage is significantly increased.

The ease of assembly of the reinforcement cage allows you to perform the necessary work, even for one person, when it comes to building a private house.In addition, the installation of bored piles with a metal frame does not produce much noise.

For information on how to make a reinforcement cage for bored piles, see the following video.