Subtleties of arrangement of a floor in the frame house

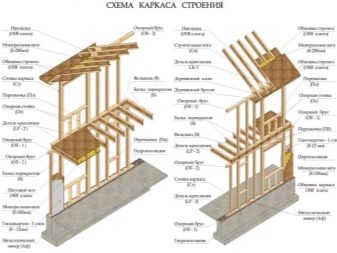

The construction of buildings for any purpose is impossible without the fundamental elements of the structure. The foundation and the floor, which are the basis of the whole house, primarily belong to a number of such components.

Special features

The device frame structure also includes a set of works on the arrangement of the floor. Properly designed base, made with the use of high-quality building materials, in the future will help eliminate loss and heat release through the floors, and as a result will maintain a comfortable temperature for homeowners.

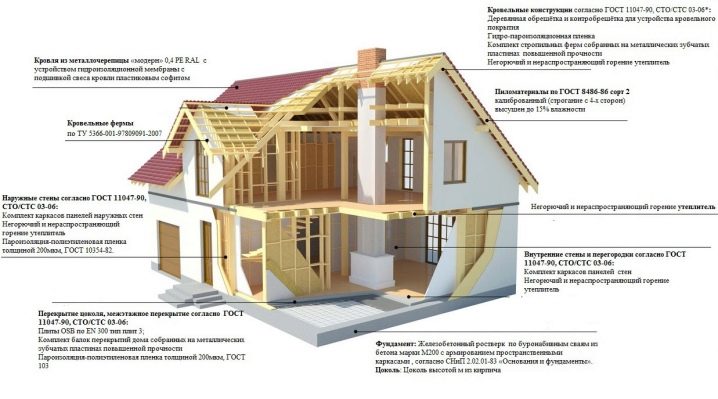

Based on the features of the technology for the construction of frame houses, the foundation of buildings can be of the following types:

- structure built on screw piles - this option is ideal for soft soil where construction is planned;

- concrete pillars, the installation of which should be carried out in a more solid ground;

- tape foundation;

- the design created from the monolithic reinforced slab of concrete, which is laid on a solid pillow of sand.

The selection and construction of one of the types of foundations for a frame house is the first step in the construction of such a building. Experts recommend that you carefully consider the selection of wood to create a frame house, taking into account the climatic conditionsand a number of other important points, since such houses are a capital construction that can be fully exploited for a long time.

Most often for work on the device of the floor in the frame house prefer coniferous wood due to the fact that the raw materials have high durability and low cost. Lags made of aspen or oak are expensive products, which is due to higher quality characteristics.

For work with the foundation of the floor, it is necessary to acquire well-dried raw materials, since humidity helps to reduce the size of the products, which leads to the appearance of gaps between the laid products.

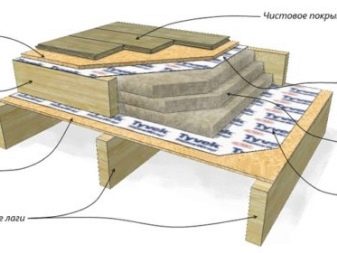

The base in the frame house is made by installing a draft and finishing floor. You can make a rough floor using OSP boards, which are fixed to the lower parts of the harness and lag. After that, the rest of the materials responsible for creating the floor in the frame house are laid on the created surface. According to this technology, the constructional foundation cake is created.

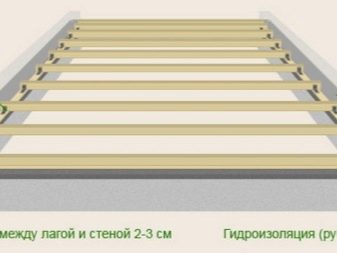

The draft floor is laid according to the following principle:

- A lag, pre-treated with an antiseptic, is installed above the building base piling. It is necessary to choose raw materials more moisture-resistant, for example, larch, because it is the least subject to the process of rotting;

- board section is selected based on the distance between the walls. If it is quite large, then it is worthwhile to increase the cross-section of the products, or else to make additional support from concrete or brick pedestals;

- the main task is to achieve a foundation so strong that wooden logs do not bend under loads when people move along them or under the weight of installed furniture;

- step frequency when laying wood should be determined on the basis of the dimensions of the laid OSB;

- a bar on which an edging board is laid is nailed to the lower part of the lag;

- all sections of the subfloor must contain waterproofing in the form of a film;

- In addition, the gaps between the lags are filled with insulation, which is covered with a vapor insulating material and moisture-resistant plywood.

On top of the subfloor installation of a finishing base. It is a topcoat, which can be in the form of parquet or floorboard, ceramic tile or laminate.

Kinds

The floor in the frame house can be arranged in several ways. The choice in favor of one or another option will be based on the frequency of living in it. So, in the summer house, the issue of creating the base of the floor is somewhat simpler, and in buildings of frame type, which are being built for permanent residence, it is often necessary to do additional warming, which consists in installing a floor heating system. Taking into account the configuration and type of existing foundation, as well as financial capabilities, there are several types of flooring.

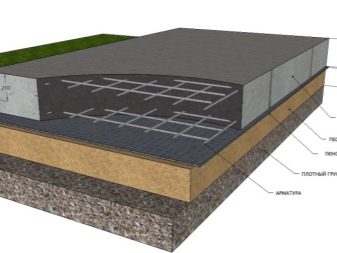

Monolithic floor

Such a foundation is made on a concrete screed. The design has the following positive qualities:

- long service life;

- resistance to severe stress on the surface;

- the base is ready for arranging the system of warm floors.

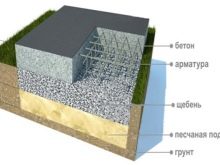

Concrete screed is carried out after a series of preparatory activities, such as:

- soil leveling works;

- making a sand cushion;

- laying a layer of rubble on a sand pillow.

Fill the screed in such a way that no voids remain on the surface. As a rule, it takes about 3 weeks to completely set the black base.

After working on the creation of a tie, the cut of the cake can be represented as follows:

- a pillow of sand and a layer of rubble;

- screed with waterproofing and insulation;

- vapor barrier material;

- floor heating design;

- finishing screed and flooring.

Frame floor

Such a structure is erected on a columnar, pile and strip foundation. Its features are to create the design of bearing and intermediate beams and lag. Arrangements for the arrangement of the frame type of the floor begin with the preparatory work associated with the installation of the floor.They are boards that are stacked on a foundation with a waterproofing material. In addition, anchor bolts are attached to the products.

The method of laying the bed makes it possible at the end of work to get on the surface of a rigid and durable structure. In addition, cuts are made for logs. Section of products for each room and floor may be different. Experts recommend using beams with a cross section of 100x250 mm for the first floor, 70x200 mm for the second floor, and materials with a cross section of 50x150 mm should be purchased for bathrooms and showers. Lags are attached to the board, which subsequently settles the draft floor.

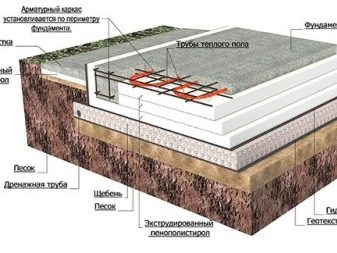

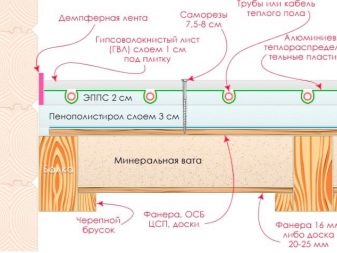

Pie floor on stilts in the cut is as follows:

- 6 mm thick OSB;

- waterproofing and sound insulation;

- insulation;

- shield of OSB;

- extruded polystyrene foam.

For country houses, a frame cake of a floor consists of the above components, including such additional elements as:

- foam foam substrate;

- gypsum fiber sheets;

- any fair covering.

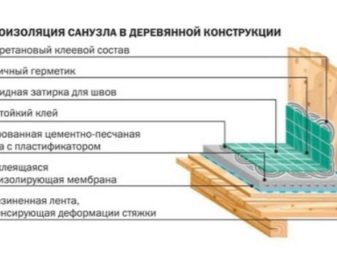

For the bathroom and kitchen, as well as any other rooms where the humidity level in the room will be high, and also requires heating in winter, the pie will look like this:

- vapor barrier material;

- reinforcing mesh;

- contours of a heat-insulated floor;

- waterproofing;

- screed;

- a layer of foamed polystyrene;

- finishing base.

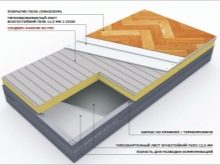

In buildings where permanent residence is planned, the arrangement of a heated floor is mandatory. In this case, the constructive floor will be such as:

- aluminum plates;

- floor heating system;

- foam substrate and GVL;

- any kind of base finish.

Installation

Frame floor can be equipped with its own forces only in the case when you have at hand all the necessary tools, as well as a clear understanding of the recommended rules and rules for the performance of work. Flooring is made of materials that are selected based on the individual preferences of the owner of the building.

When stopping your choice on a decorative flooring of a grooved board, you should consider the technology of its installation, which includes the following steps:

- material is laid across the genital lag;

- fixing products made with nails;

- at the end of laying the floor loop;

- the final stage of the work is varnishing the boards.

Important: besides boards, quite often they prefer to make flooring from plywood.

The technology of mounting sheets is made according to the following scheme:

- the marking and arrangement of products is performed with the consideration that the joints of materials will be on the logs;

- Lags are treated with an adhesive composition, plywood is laid, attaching the sheets with screws or nails. Processing with glue will eliminate the formation of squeaks during the operation of the house;

- a small vent should be left to ensure that the base does not deform as the moisture level increases;

- where there are various communications and pipes, you need to make special holes in the plywood sheets;

- the alignment of the edges of the material takes place on the trimming board, marking and trimming products.

Upon completion of work with the arrangement of the floor in the frame house, proceed to work on the creation of the frame walls and roof, followed by covering the house.

Tips

In order to accomplish the arrangement of the floor on the second floor of the frame structure, it is necessary to follow the recommendations on the performance of work, which are somewhat different from the technology for creating the floor on the first floor.

It should be noted that the main task of the floors on the second floor will be to create high-quality sound insulation. Therefore, instead of the usual insulation in the interfloor overlap, it is necessary to use a sound insulating layer. The most suitable raw material for such works will be sand, which meets the necessary characteristics, and in addition, is an excellent accumulator of heat. Equally important is the high level of stiffness of the slab.

To ensure these qualities, the base, in addition to beams, is to be reinforced with lags, which will add strength to the structure.

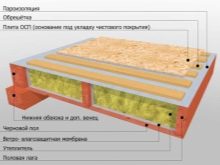

The technology of mounting the floor on the second floor involves the following work:

- installation of the draft base to interfloor beams;

- laying waterproofing and vapor barrier;

- in the gaps between the beams, the installation of insulation and raw materials, providing sound insulation. In some cases, clay is used instead of sand;

- floor beams are installed on the beams;

- the distance that exists between the lags is carefully filled with raw materials for insulation. For such purposes, mineral wool or any other building material with high non-inflammability is usually used;

- A waterproofing film is placed on top of the insulation, which will prevent the formation of moisture leaks on the first floor in case of unforeseen situations, for example, a leak in the roof;

- the cake is sewn with a board, plywood or other material suitable for further work on laying the finishing floor covering.

Some builders recommend to simplify the constructive floor of the second floor, using beams with reinforced construction for the floor decks. These products are I-wood products. When you create such a construction installation lag is not required. The beams are sewn up with a board, between them the laying of sound-insulating material is carried out, which must be sealed.

Having studied the properties of building materials, you can avoid mistakes when arranging the floor in a frame house, since a competent combination of raw materials into a single structure will ensure a high level of comfort of this kind of dwelling.

Beautiful examples

There is no more attractive and environmentally friendly material that can be used in construction and decoration than natural wood. The implementation of the floor in the frame house using natural raw materials will emphasize the originality and at the same time the simplicity of the design of the bedroom or living room in the house, because even after processing the product will retain the unique wood texture.

Flooring tiles, which form intricate patterns or imitate the foundation of a stone, combined with products of different shapes, textures and colors in combination with additional heating of the base, the system of warm floors will decorate and highlight the entire design in the house, pleasing the eye and providing comfort when in contact with the foundation .

The technology of the device floor in the frame house, see below.