Frame house do it yourself: technology and stages of creation

The construction of frame houses in our country is becoming more and more popular. All new technologies are part of such buildings, and it does not matter whether the house is built on technology - Finnish or Canadian. This article describes how to build a frame-type house with your own hands, and also describes each stage of the construction of a building of this category.

Features of construction

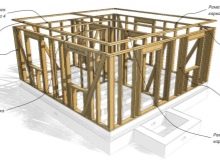

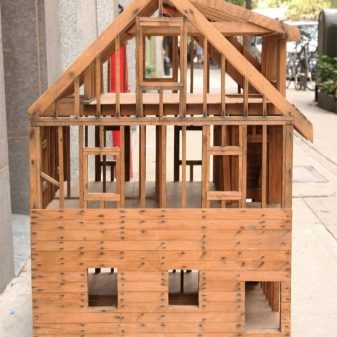

The frame house is a building, which is based on the frame. In general, it is clear from the title. In itself, the frame is the basis and a kind of "skeleton" of such a structure. The frame is installed on a previously prepared foundation, after which it is sheathed with special panels.It is insulated and built the roof. After completing all these steps, the output is a finished house.

It should be noted that the frame houses first appeared in Germany, and then a wave of their popularity swept Canada and the United States. For this reason, there is more than one technology for the construction of a frame house - Canadian, Swedish, German, and so on. In the USSR, such houses began to be built in the 50s of the twentieth century. And since that time, interest in buildings of this type has increased significantly and continues to grow at a rapid pace.

Advantages and disadvantages

Like all buildings, frame houses have advantages and disadvantages.

If we talk about the benefits, it should be noted:

- Low construction cost. This technology is considered the most affordable, even if we take into account the cost of decoration and foundation.

- High pace of construction. Three builders are enough a month to build a medium-sized house. And if you still build a foundation and carry out finishing work, it will be enough for them for 1.5 - 2 months.

- Low operating costs. This type of house does not require constant maintenance, unlike the same wooden houses, where it is required to update the facade from time to time.

- Excellent sound insulation in the rooms. If inside the ceilings, walls and partitions to install sound insulation, you can achieve pretty good results in this matter.

- The ability to build communications inside the walls. One of the peculiarities of such a technology will be that it is possible to lay electricity, heating pipes, water supply and so on inside the wall at no cost and using special tools. From an aesthetic point of view, this is a very big advantage.

- The possibility of building a lightweight foundation. Thanks to this technology, you can use the so-called lightweight foundations of low bedding, which allows you to save and increase the speed of construction.

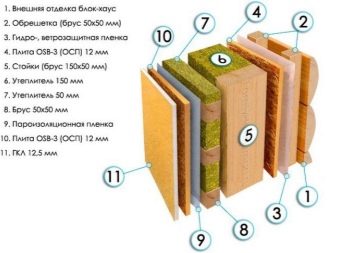

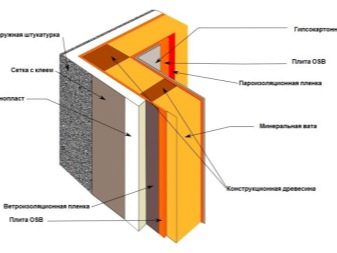

- Environmental friendliness. The main components of the frame house, in addition to the frame itself, are insulation, basalt and mineral wool, gypsum plasterboard, as well as oriented strand board OSB. All this is the result of processing only natural materials that increase the performance characteristics of the building and do not pose a threat to humans.

- Seismic resistance. Houses of this type can withstand earthquakes up to 9 on the Richter scale.For this reason, such buildings are extremely popular in countries such as Japan.

- The possibility of construction at any time of year. There is no restriction on building a house in any season, if the temperature is not less than -15 degrees Celsius. That is, the construction of such a house in the winter is very possible.

- There is no reason to use heavy construction equipment. Just a few workers are enough to build such a house in a short time.

- Easy access to the contents of the wall and floors. The design of this house is made so that getting to the insulation or internal communications is not a problem. This makes it possible to constantly upgrade the house and improve its technical characteristics.

- The possibility of quick and not too expensive dismantling. Thus, the house can, if desired, be transported and assembled elsewhere.

- Not too big wall thickness. This makes it possible to save extra square meters and make the interior more.

- Low thermal conductivity and heat capacity of various designs. That is, you can significantly reduce the cost of heating in the winter, and also, if necessary, cool in the summer is easily maintained.

- No shrinkage. That is, after construction, you can immediately begin the implementation of the finish, which means that you can move in as quickly as possible. Also, there is no need to do additional space heating, there is no risk of skewing walls during shrinkage, and so on.

- No wet cycles in construction. The construction of the house becomes the most independent of the sources of water supply and the temperature outside the window.

- A large number of defrost and freeze cycles. The house can be used seasonally or on short visits and it makes no sense to maintain some temperature when there is no one there. And warming up the house takes very little time.

- Comfortable indoor climate. The use of wood or drywall makes it possible to retain all the characteristics of a wooden house, namely the ability to diffuse gases, to take and give moisture to the frame structure.

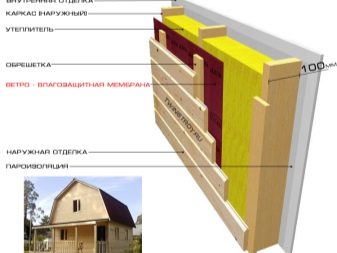

- No gaps. The great advantage of such houses is the presence of even, almost perfect surfaces, which makes it possible to eliminate the appearance of cracks and holes. And even if they are, they are perfectly filled with insulation. Moreover, the use of the same wind and waterproofing membrane eliminates the ingress of any air masses into the wall.

- The simplicity and ease of interior decoration. A big plus of such houses is the absence of the need to plaster the walls or create a frame. It is enough just to fill the joints and places where there are screws and everything - you can glue the wallpaper, because there is no need to align the walls.

Also, there is no need to do floor screed, because the floor is already initially ready for finishing. Saving time and money is also evident.

Noting all the advantages of these houses, one can not but mention some of the disadvantages:

- We need a fairly high-quality project, and also drawings, where fastenings with knots will be displayed. Technologically, such a house is somewhat more complicated than an ordinary one, and requires certain skills of builders, the availability of a number of tools, and so on.

- The echoing of floors and wall structures. This minus is in all floors and wooden walls. It is associated with a relatively small weight of the structure, which does not adequately dampen serious vibrations. Partially this problem is solved with the help of heat and sound insulation from the 2nd layer of gypsum board, heavy and dense basalt-mineral insulation.

As you can see, the advantages of this type of houses are much larger than the disadvantages, which means that choosing such a building is a pretty good decision.

Types of buildings

If we talk about the categories of frame houses, there are a lot of them. If we consider the methods of construction, then there are such houses:

- frame-panel or panel;

- frame-timbered or Canadian;

- rack-and-beam or half-timbered;

- frame with uncut stands;

- frame and waste structures.

All other options can be either with small modifications of such houses, or they are a combination of different solutions. Now we will tell about each of the above options in more detail.

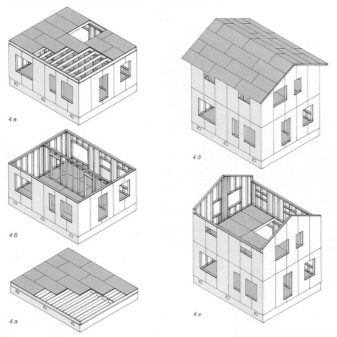

Frame-shield houses are usually produced at the factory. According to the project, a framework is first made, followed by panels, floors between floors and even roofing. Each element receives the necessary markings and all the necessary holes. In fact, it is a kind of designer. When the house kit is ready, it is simply delivered to the construction site, where its direct installation begins.

This technology is very simple, but in order for the house to be of the highest quality and durable, you should follow all the rules and norms of its construction.

If we talk about frame-frame or Canadian houses, then we must immediately say about the so-called CIP panels.They are a structural insulating panel, which is a heater, which is framed in sheets of OSB. This option is a reinforced version of the panels for frame-panel houses. The structure of this type will be built on technology "Platform".

Three layers of such a panel are connected to each other with the help of a bar “thorn-groove” using glue based on polyurethane foam. In the production of CIP panels, polyurethane foam is also used, which is a fairly high-performance insulation. In order to increase strength, the above layers are pressed.

It should immediately be said that high-quality SIP-panels can be manufactured only in factory conditions.

Another option houses - it made by German technology. In fact, this is one of the options for using the methodology of the platform. This technology involves laying insulation in boards and communications. Installation of windows, assembly of floors and primary wall decoration are also carried out. All this is done only in the factory. A rather serious disadvantage is the need to use lifting mechanisms.

If we talk about the frame-frame method of construction, then it has a significant difference from the panel: the assembly of the frame of the house is on the construction site in the form of frames that are not sheathed. Only when the installation of the structure is completed, does its trimming and insulation begin.

Such houses are the best solution for those who want to build a house on their own. The advantage of such houses is that the owner sees completely what the house is made of, how the work is done and the assembly is done.

It should be noted that the frame of the house can be optionally made of wood. Now popular are metal frames, made of light steel thin-walled structures and so on.

The use of this technology makes it possible to realize the most interesting architectural plans not only at the initial stage, but also later, if you suddenly need to carry out redevelopment.

Another type of houses, which is being built by German technology - rack-and-beam, or fakhver. This technology is quite many years, and it involves the construction of houses from the sections. They are made of horizontal beams, vertical pillars and stitches.The feature of the fakver is that the frame with beams does not hide behind the cladding, but is just taken out from the outside of the house. Usually, the frame is made of a thick bar that has a cross section of 100 by 100 or 200 by 200 millimeters.

The space between the beams and racks is filled with certain materials. Previously used blocks of straw and clay. Now they use brick, OSB slabs, adobe material, and so on.

In our conditions, doing this type of house is not worth it, since the construction will require quite serious insulation. But this view has a rather original look.

And the last type on which attention should be paid is frame-frame constructions. Such houses with uncut drains are also called Finnish. They are somewhat similar to houses that are made using Swedish technology. Solid vertical stands that pass through two floors are the main element of the frame. In order to ensure high structural strength, racks must be installed strictly vertically.

The overlaps between the floors are installed on the support boards, which were embedded in the beams.The continuous racks are strung together by the overlapping lags, the design becomes rigid. This type of construction is characterized by the fact that the vertical uprights perform the role of piles. It is on them that the main burden falls. You can also increase stiffness with horizontal beams.

Device design

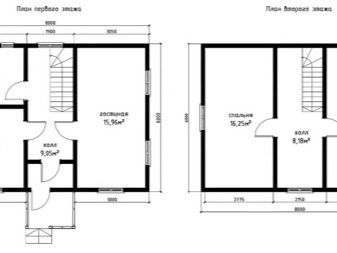

Creating a design begins with the development of a competent project. Drawing with the size of the house and in general the most complete construction scheme, where not only the structure is depicted, but all its elements are drawn as much as possible - this is the best option that should be. In the project, which, by the way, must fully comply with the SNiP, engineering, constructive, architectural, construction and other features should be reflected as much as possible. For example, if it is supposed to make a cross-house with a mansard, then it should already be in the project.

All this is done to ensure that even a person who is not too versed in the construction of houses can realize engineering ideas as easily as possible.

And if necessary, you can see how this or that house will finally look on the website of the contractor organization from which you expect to order the project.Also important point concerns the regulatory documentation. The fact is that such a technology does not forgive errors, and therefore, to be sure that your project fully complies with all standards and GOSTs, it should be independently rechecked by SP 29-105-2002, entitled “Design and construction of energy-efficient single-family houses with a wooden frame”.

Rules of erection

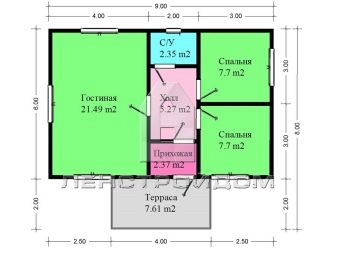

If we talk about the rules for the construction of such houses, then the main principle is that the construction technology must be strictly observed. That is, the house has a proportion of 4x4 or 6x4, it should be so. Or if the size of a room should be 3x6 m, and in some room the element 10x10 should be used, then it is necessary to follow such dimensions.

Any deviation runs the risk of disrupting the entire construction process and the result can be quite deplorable.

Construction should have the following steps:

- creation of the base;

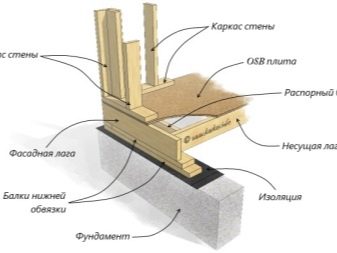

- piping, creating insulation and flooring formation;

- making walls;

- the formation of floors and work with them;

- the creation of the truss mechanism and the subsequent formation of the roof;

- work with insulation.

Only in such a sequence can frame houses be erected, otherwise you risk creating a building whose efficiency will be significantly lower than the planned indicators.

Selection and calculation of material

Before embarking on construction, you need to choose the material from which you will build the house, and also calculate how much you will need it in order not to overpay for nothing, but at the same time it was enough for the implementation of all the conceived ideas.

First of all, you should think about the consumption of lumber. But it all depends on what you will make a frame house: from wood, from timber or maybe plank. For example, for the construction of a panel house we will need:

- timber of various sections;

- edged board with a cross section of 2 centimeters, as well as the same board, but with a cross section of 5 centimeters;

- boards grooved with a cross section of 2.5 centimeters.

It’s not so easy to calculate the cost of a rack and crossbar. Here we should take into account the size of the future structure, that is, its area, as well as the category of thermal insulation material that will be used in construction.

Also, if we talk about the consumption of other materials, you will need to do:

- foundation;

- hydro and thermal insulation;

- wind and vapor barrier;

- roofing;

- internal and external decoration;

- various engineering communications - electrical wiring, drainage, snow guards, sewage and so on.

By the way, the calculation of these systems needs to be done only when the owner of the house has decided on the roofing material and the box of the house. It is from these two moments that it is required to make a start in the future.

Naturally, if a person is willing to spend money to form a reserve of the strength reserve of a building, then such a thorough calculation can no longer be carried out. But, as a rule, frame houses are built just for the reason that they are cheap and affordable.

Instruments

Creating a frame wooden house can be done with the usual set of tools. This is another beauty of frame technology for ordinary people. There is no need to use any special equipment or any expensive tool. But at the same time, if you cut the boards with a simple hacksaw, and hammer the nails with an ordinary hammer, you can build a house for years.

If it is possible to use a pneumatic or electric tool, the result and speed of construction will improve significantly.

So, for work at different stages will need a variety of tools. For example, during site preparation and foundation work you will need to have:

- shovels and bayonet shovels;

- wheelbarrow;

- Boer;

- buckets;

- roulettes;

- plumb lines;

- markers;

- the pencils;

- water levels.

At the stage of assembly of the frame, we need:

- saw;

- drill puncher;

- plane;

- nail puller;

- ax;

- hammer.

In addition, you will need various auxiliary elements - ropes, electric extension cables, as well as small tools, including fasteners of various types and nails.

Significantly accelerate the construction and will not be superfluous modern tool. For example, the preparation of parts of the frame is more convenient to do with an electric circular saw. It is even better if a special end saw with a stationary base is used for work. And the same electric disc saw would be an excellent option for mounting the frame.

For fast and high quality nailing, use a pneumatic hammer withcompressor. This tool can not be called cheap, but then labor productivity will be much higher here.

In addition, in the process of assembling the frame it will not be superfluous to use an electric planer, as well as an jigsaw. The plane is needed to correct defects in lumber, as well as in order to fit the frame elements to each other. A jigsaw will not be superfluous for accurate installation of the roof truss system.

Step-by-step instruction

As already mentioned, frame houses are built exclusively on well-established technology, that is, in stages.

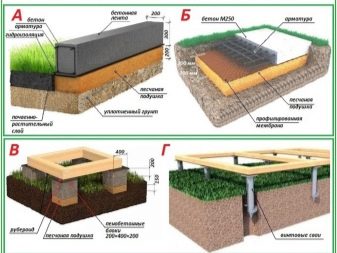

Foundation

Creating a foundation is a rather complicated and very important process that sets the tone for a successful project at home. When creating the foundation, it is necessary to take into account a lot of factors, ranging from the geological picture on the site and ending with the height of the location of groundwater and so on.

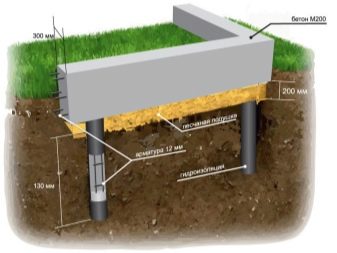

As a rule, pile-grillage foundations are most often made. They can be quickly built, they are reliable. In addition, this basis does not require large material investments.In addition, such a platform will evenly transfer the load to all supports.

Drilling wells for piles must be drilled. As a formwork, you can use roofing felt rolled into pipes of a certain diameter. 3-4 rods of reinforcement are installed inside the piles, which are interconnected in the form of a square or a triangle. They must be cut so that at least 70-80 centimeters of the rod protrude above the surface of the pile.

Pour all the best concrete brand from M25 and more.

After the piles have been poured, formwork should be installed into which the reinforcement will be laid. We connect longitudinal bars with curved parts of reinforcement from piles. You should also leave holes in the ribbon for communications and ventilation. In a tape of the base the bar for a binding will be attached then. To install it, the studs are fastened in the ribbon. They are put through every meter or two.

From each corner to both sides, it is necessary to retreat by thirty centimeters. Here studs are required. In other places it depends on the size of the house, but you can not mount them less than two meters. It should be said that the studs are the only link between the foundation and the frame of the house. Therefore, it is better not to be greedy. Generally, the studs must be at least two in one wall.

When everything is ready, you need to pour concrete. After that, so that he does not cope, but becomes stronger, it is better to cover him with polyethylene. If the temperature after filling the foundation is kept at around + 20 degrees, then after four or five days, construction can continue.

In this case, the concrete will already have 50 percent of its strength. And if the temperature is lower, the waiting time will be longer.

Floor

In order to make the floor, you must first waterproof the foundation. To do this, you must use waterproofing, bitumen mastic and roofing material. First, liquid insulation is put in, followed by a line of roll insulation, and already above the deck are mounted - dry boards. Their edges should be leveled at the foundation height. The second layer of boards is placed on the second layer in order to hide the gaps that may form.

Strapping boards are attached to the deck beds. They must be put on the edge, leveled, and then attached with nails to its foundation. Now the installation of the lag is carried out - everything will be the same as when installing the harness. That is, they can be nailed with oblique nails.

Now you can start to warm the floor. There are lots of ways to do this. One of them is the use of low-cost polystyrene foam. Its thickness should be 15 centimeters. It is laid in two layers to block the seams and joints. You can also walk around the perimeter of the sealant to ensure maximum surface insulation. After isolation, it remains to lay the rough floor of the boards, as well as a layer of plywood.

If it is large and about 1.5 centimeters in thickness, then you can do without a repeated layer. And if not, then overlapping another layer of boards with the first level is necessary.

Walling

The next most important stage - the construction of the walls of the house. At the same time, there are two options: either to assemble the wall frame on the floor, then simply lift it, set it and fix it, or assemble everything in place gradually. In the first case, work is usually carried out in factories, but in the second, when the assembly is done by hand. To begin with, the lower ulcer nail is nailed, after which the corner posts are set, then intermediate, the upper trim. This technology is also called ballun.

Each option has its pros and cons, but everything will depend on how many people work at the facility.

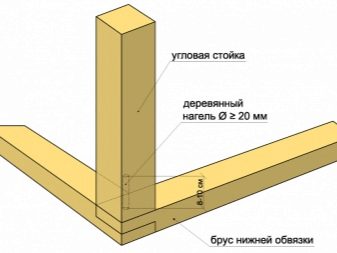

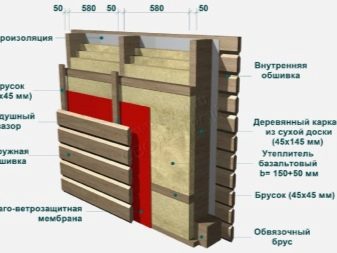

If we talk about corner racks, they should be either 150x150 millimeters, or 100x100 mm. In rare cases, 50x100 racks are used. But then everything will depend on how small the house is built. If small, then 100x100 mm option will be more than enough. It will still depend on the load and the required width of insulation.

The pitch of the racks is selected taking into account the load, but even the distance between the racks is selected based on the width of the insulation. The gap between them should be a couple of centimeters less than the width of the insulation. Then there will be almost no garbage, as well as cracks with gaps.

That is, you should first set and fix the corner beams, then mount the top trim on them, and only then with the selected step vertical stands. Mounting racks possible in several ways:

- using wooden pins;

- on the corners;

- with a cut.

The hem into the bottom trim should be no more than half its depth. Corners are usually attached on both sides. Mount on the nails - the old technology, but its execution is quite difficult. It is best to use reinforced corners.

The beams to which the doors and windows are attached must be double. In this case, the load is greater, and therefore the support is required more powerful.

Now about the braids and braces. If the outer skin should be of high strength material, it is better to cut the stitches from inside the room, since they will be temporary. This is necessary to preserve the geometry, while there is no outer skin. If the paneling is a typesetting, then the permanent strut should be necessary. It’s best to use four small pieces each: two at the bottom and two at the top.

But most of all the question arises when building corners. This is not surprising, because these are the main nodes of connections. If the timber is located in the corner, then there will be no problems, except for the fact that the angle will be cold. But you can make the frame of the house warm.

After the frame is assembled, it should be sheathed with plywood or OSB. This will not only be an excellent heater, but will also act as an excellent sound and noise insulation.

Overlap

Overlapping beams should rest on the top trim bar. There are several ways to mount:

- with sidebar;

- on the corners;

- on steel support brackets.

The dimensions of the beams and the distance between them will depend on what is on top. If this is the second residential floor or attic, then the cross section must be taken more, and the step should be taken less to avoid bending the floor.

If there is only a roof on top and the attic is uninhabited, that is, in fact, we will have an overlap of the first floor, then it will be completely different calculations. And if the overlap of the second floor, that is, exactly the floor, then the calculations will be, as in the first case. In the one-story house, the floor beams at the same time are the support for the rafters. It is for this reason that they are released thirty centimeters beyond the perimeter of the wall.

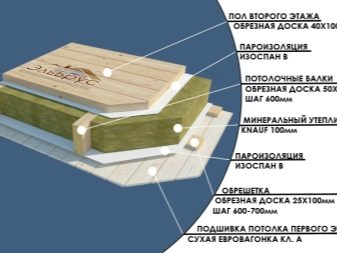

If the second floor is being completed, the flooring is sheathed with a draft floor of the second floor, and the ceiling should be covered from below. That is, we get a kind of small "pie". In this case, working on the creation of the second floor of the house will be easier, since its assembly will not differ from the first.

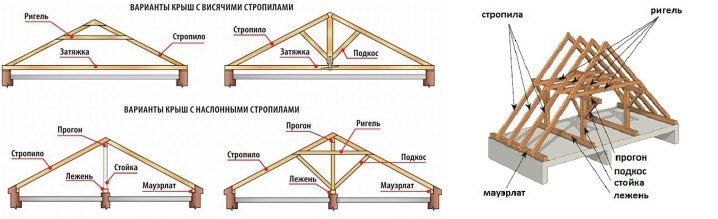

Roof

The roof is installed already when all the walls are finally built and fully fixed. It remains to determine the required slope and what the roof will be. The most common is the gable.In order to increase the usable area of the house, a number of buildings are equipped with a veranda. In this case, the project of the house may provide for several types of roof construction: above the veranda - shed, and above the house - gable. And depending on the slope of the roof can be:

- flat;

- broken line;

- straight.

Rafters are selected in such a way that between them it was possible to carry out the installation of insulation. As a sample, they take two boards six meters long and connect them into a L-shaped structure. Then they are lifted onto the roof, supported on a binding bar so that the overhangs are 35-50 centimeters. Now the construction is fixed with a transom and is used as a model for rafters, which are mounted 70 centimeters apart.

Their connection in the skate is carried out according to the technique in “half paws”. That is, the rafters are first installed on the gables, after which a thread is pulled between them, according to the level of which all intermediate rafters are mounted. After that, solid or thinned crate is put. That is how the truss system is done.

If we talk about the coating, the composition of the roof may be different. As an example, consist of metal tiles or profiled sheeting. The latter is very easy to install, has a relatively small weight and low cost. But he may have different layers - for example, you can install a sheet of corrugated board and a layer of metal tile.

Windscreen

To protect the frame house from the effects of natural factors, a special wind-proof film is used. It refers to the exterior materials for the facade. It is better to mount it in warm weather. Works can be started only after the completion of the laying of the main insulation layer, as well as before the final decorative wall lining. TOAs a rule, the main insulating layer is a special membrane.

In order to eliminate errors in the installation of such a film, you should pay attention to the structure of its sides from the outside: one is smooth, and the second - with a nap. The film is laid side, where there is a pile, to the insulation.

Film rolls should have the manufacturer's logos on the surface, which is a hint how such a film should be laid.

Layout windproof material can be carried out vertically and horizontally. It is better to use the vertical option. A horizontal strip of film will simply interfere with its gradual installation.

The installation of the film should be carried out from top to bottom, with the end of the roll, which is free, is applied to the upper part of the wall and rolled out to its base. You can cut the material with scissors. As an alternative, you can consider a stationery knife. The length of the piece of film that will be cut off from the roll must have small allowances so that you can run the material between the wall and the main insulation.

In no case should sagging material. Such a film is fixed with plastic dowels with plate-shaped caps that perfectly attach the film to the wall. For one square meter will be enough of five such dowels. Installing the next strip of wind-proof film, you should do it overlap, so that there are no places to which the impact will go.

Ventilation

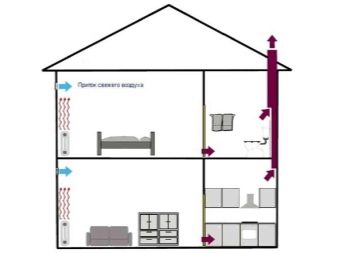

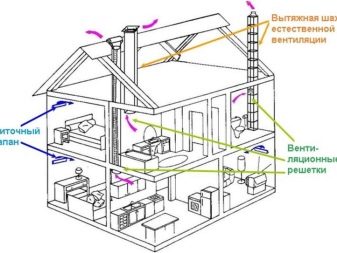

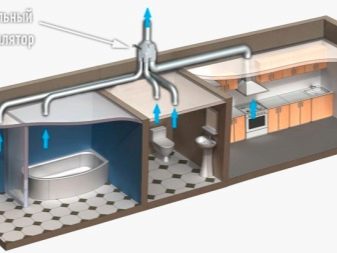

Ventilation in frame houses can be of two types:

- natural;

- artificial.

Natural is characterized by the flow of fresh air through doors and windows, and the exit is through ventilation ducts in technical rooms. This is possible due to the difference in air pressure outside and inside the room.

But in the frame house natural ventilation will be weak, since such a structure will be airtight.

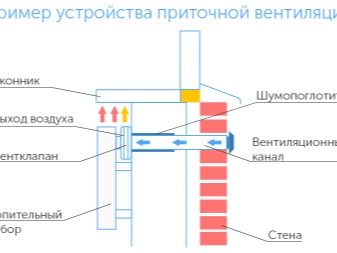

Do the same ventilation in a house with your own hands, you can use the supply valve. Ventzazor can be made by hand from plastic pipes. Asbestos-cement can also be used, which should be carefully incorporated into the frame to get a ventilation gap. Said valve allows air to flow.

Outside, it is covered with a grill to avoid the ingress of foreign objects inside. There are installed filters for primary air purification, as well as a silencer. The air flow can be adjusted using the damper. The scheme of the inlet valve is very simple and you can do the installation by hand. It is necessary to make a through hole in the wall, insert a pipe with noise insulation into it, a filter, fix the grid and make a gate.

It should be said that the natural method of ventilation is very inefficient and in this case at least an exhaust hood or a ventilated facade is needed, since such a system cannot simply resist the formation of a fungus.

In order to ensure good traction, you can equip the system with a fan. There are also examples when moisture meters were installed that can automatically turn fans on and off.

Warming

It is possible to warm the frame house any material with the corresponding characteristics. Of course, the ideal material does not exist, but you can find the optimal solution.

Basalt wool is the most popular insulation today. It is made in the form of mats and rolls, each of which has a different density indicator. It is better to put mats in the walls: their density is higher and they hold better thanks to the arching force. But for this, their dimensions should be two to three centimeters more than the distance that there is between the frame racks. Mats are fixed with special fasteners, but they still work better with them than with soft rolls.

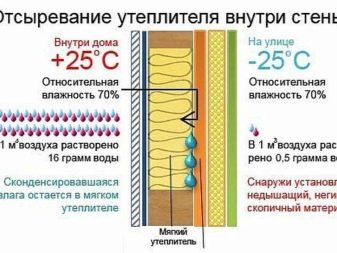

Minwat has excellent thermal insulation performance.But she has a big disadvantage: she is afraid of moisture and should be protected not only from this, but also from the effects of steam. That is why from the side of the room it should be closed with a layer of vapor barrier membrane so that the fumes do not penetrate inside.

If you take the outer side, the insulation of mineral wool is closed by another membrane, but of a different type. In this case, the membrane will not be blown and will not allow water to pass in a gaseous and liquid form, and couples will be able to leave the insulation without problems. That is, vapor tightness will be one-sided. When the insulation is installed, it will be necessary to carry out only finishing work.

Installation of windows

According to the accepted norms of construction, windows should be about 18 percent of the wall area. And for maximum illumination it is best to stick with these sizes. If you live in a house all year round, it is best to install a plastic double-glazed window with double glazing and a large glass area.

How to handle the house?

In order to protect the house from temperature extremes, various pests, moisture and exposure to various microorganisms, it should be treated with an antiseptic. This can be done in three ways:

- With a brush. This is the easiest and oldest way to apply antiseptic. In this case, concentrates should be taken, which should be diluted with water before use. As a rule, apply two or three layers of antiseptic, which was diluted with water.

- Using a spray bottle. This method significantly saves time, which must be spent on this type of work. An antiseptic solution made in advance is poured into the sprayer, after which the mixture is sprayed onto the desired parts of the house.

- Immersion of the desired item in a container with an antiseptic. Immersion in the solution should be carried out strictly for a certain time in order to preserve the properties of the tree as much as possible. In order to carry out processing by this method, not only a large tank is necessary, but also a special mechanism for lifting heavy elements.

To prevent the wood from floating, it is necessary to use clamping systems.

The advantages of antiseptic treatment are:

- increase the life of the building;

- preventing not only the harmful effects of insects and microorganisms on the building, but also the destruction of parasites,which is already in wood;

- there is no negative influence of antiseptics on the structure, color, and strength of wood;

- improving the resistance of treated structures to fire.

Finishing options

Options for finishing there are several. Can be just put the plaster on the outside, and you can use paint. You can also make the wall siding or clapboard. If desired, it is possible to use a block house.

For example, plastering can be done in two ways:

- Plastering is being done on sheets of facade foam that were previously attached to the facade with glue, as well as special pressure dowels.

- Plastering is done directly on the OSB-sheets with joints, pre-treated with a frost-resistant sealant. Also, the walls should be covered with glass cloth mesh and primed.

But this method is more suitable as a temporary option.

Common mistakes

When building houses it is important to do everything correctly and avoid various kinds of inaccuracies. From the correctness of calculations, the rational use of building materials, compliance with the technological moments of insulation,as well as the trim will depend on the final result - will you have a beautiful, comfortable and cozy home, or will you get something completely different from what you expected. Therefore, it is worthwhile to consider the main errors of frame construction in order to prevent their commission, especially if you want to carry out the installation yourself.

One of the most common mistakes is the wrong selection of lumber for a wooden house. As is known, the basis of the frame house is made of wooden materials. And one of the main mistakes is their wrong selection. In one case, the construction does not use well-dried wood, that is, fresh lumber. And in the other, wood of small section is used, which simply cannot withstand the operational loads.

The first mistake is much more serious, because its assumption can really affect the quality and reliability of the house structure. After all, the fact is that wooden elements change in size as they dry out. Therefore, there may be cracks, distortions and other problems, which then make the building uninhabitable.

Wood of small section does not withstand the necessary loads and its use in the house is simply dangerous.

Another important point is the lining of the frame structure.Only the correct implementation will ensure the stability of the house with wind lateral loads. In this case, the best solution would be an integrated approach, when the frame lining is done with the help of plate materials, as well as installation of mowings in the lower and upper parts of the harness.

Hoping to reduce the cost of construction, you can quite seriously miscalculate. Especially if you decide to use some kind of budget insulation, the performance of which leaves much to be desired. The best insulation today are:

- basalt wool;

- mineral wool;

- insulation based on cotton wool.

Everything else is extremely risky to use. And in general, save on insulation should not be.

You should also as closely as possible to comply with the technology and constructive construction. Usually it is a question of either “balun” or “platform”. They have clear implementation scenarios, from which it is impossible to retreat a single step, otherwise you simply risk making a house unfit for life.

Another common mistake is the wrong choice of fasteners. For example, if you fix the boards of the frame not on ordinary nails, but on black screws or perforated corners, you can disrupt the balance of fasteners.Moreover, it will be significantly more expensive and the design will not receive the necessary strength.

Also quite often mistakes are made during the manufacture of insulation, namely during the selection of film protective coatings. The accumulation of moisture inside the frame walls is a big problem for such houses. And only high quality steam and wind insulation film will help to solve it.

Build a frame house with your own hands is a realizable task, although it requires serious concentration, an understanding of construction technology and a sequence of actions. In addition, you should not save on building materials at all stages of construction, because this can result in sideways in the future. But if you follow the rules mentioned above, then it is possible to build a frame country house even alone and without experience.

Review the frame house, built with your own hands, see the following video.