Technologies for the construction of houses from dry profiled timber

Wood is one of the most popular materials for the construction of individual housing. Building a house from a bar is a fairly quick process, and the possibilities of internal planning, appearance and quality characteristics will satisfy any need. However, after the construction is completed, it is necessary to wait about one year for the shrinkage to finish before operating the structure. The use of dry profiled timber avoids this expectation.

Special features

Houses from a dry bar favorably differ from houses from raw and glued timber.

Chamber drying technology takes quite a long time. The bar is dried for three weeks in a special chamber to the standard parameters. At the same time, it loses weight, the size of the material decreases, cracks and defects appear.After drying, the timber is profiled on the machine.

Many owners prefer wood just such processing technology. Today, dry profiled timber for home construction is chosen most often.

This material has a large number of advantages, among which

- quick construction and settlement after construction;

- esthetics;

- security;

- energy efficiency;

- possibility of self-erection.

Timber of this type allows you to save on thermal insulation. The fastening of the profiled bars with a lock offset along the planes significantly increases the heat-saving properties of the wall. When installed in such a way, a bar with a section of 140x142 mm, it acquires a degree of thermal conductivity similar to a rounded log 250 mm in diameter.

Sliced timber drying chamber among profiled lumber is not the cheapest category, but its advantages justify the relative high cost.

Dry-drying timber does not need to be treated with mold and rotting compounds., as when in the drying chamber all organisms and fungus causing rotting processes die.

The formation of cracks in the process of operation in the houses of the timber skipped by the chamber method is minimal. The material with cracks is rejected during the production process, a timber is delivered to the consumer, which will give thread-like cracks no more than 3 mm thick.

The choice of wood species is quite diverse: spruce, birch, larch. Despite the fact that larch is somewhat more expensive than the others, most often the choice of builders falls on it. Larch has long been considered the best material for construction. Due to the high resinous content, it is very durable, stable, not subject to rotting and insect attacks. The strength of larch, which has been exposed to atmospheric moisture for many years, is comparable to a concrete structure.

There are also disadvantages of chamber drying technology. In the production process there is a large culling material. Transportation and storage of such material requires complete sealing of the bars so that moisture from the air again does not get into the wood.

It should be very careful about the choice of material.

A timber of a large section dries longer, so there are cases when only the outer parts are dried.The middle remains saturated with moisture, and the timber remains undressed. The house of such a timber will shrink, cracks will appear.

Projects

Chamber drying beam has ample opportunities to choose the configuration of houses. Depending on the purpose of the building, you can choose the optimal wall thickness.

Seasonal homes

Bar for country houses - one of the most popular materials due to its affordability. If they are planned to live in the summer season, a wall thickness of 90 mm is sufficient. Often in country houses live from early spring to late autumn, and from time to time they come in winter. In this case, it makes sense to increase the projected wall thickness to 140 mm. Buildings of this type design one-story.

Permanent residence

The place of permanent residence should be quickly heated and retain heat well. The thickness of the walls here is 190 mm. It is possible to build walls in 210 mm, which will significantly save on heating in the future. The initial price of such a house will increase. But in comparison, for example, with a house of glued lumber with a wall thickness of 140 mm, the price of a house of dry lumber chamber drying is lower.This type of houses requires the construction of two-storey and three-storey buildings, the technical capabilities of the material allow it.

Building

Construction is carried out as follows.

Project development

Detailed layout of the floors will determine the dimensions of the building, the number of windows, doors, the purpose of the premises, the presence of extensions. It is important to make the project of bearing structures of buildings as accurately as possible, taking into account the climatic features (depth of soil freezing, rainfall rate, wind loads), loads from the structures themselves, to determine the need for vapor barrier and heat insulation at each site.

With certain skills, a project at home can be made independently. It is important to understand that mistakes can lead to economically unjustified decisions, difficulties in operating the house, deformations of the walls and roof. Therefore, it is better to entrust the project to a specialist at home or get his detailed advice.

Purchase of building materials

In accordance with the calculations made purchased lumber. The key to a strong house that will last for years to more than one generation is high-quality wood. It is recommended to buy timber from large companies that conduct an examination of their product and can provide documentation on quality control of raw materials.

Territory preparation

Before construction it is necessary to clear the territory both directly under the building itself and the adjacent one. The breakdown of the axes will determine the place of laying the foundation. It is important to set the axes in right angles relative to each other, the use of the building level here is a must. But they also prepare a place for storing building materials with a shelter from the rain or covering film.

Foundation work

Frame houses are quite light, so under them they usually lay the foundation of the tape type of shallow depth (up to 1.4 m). Depth depth is determined based on the parameters of soil freezing. First, install a sealed wooden formwork, which lay steel reinforcement. Concrete is poured into the formwork and its surface is leveled horizontally.

After the concrete tape completely hardens, it is necessary to treat the surface of the foundation with waterproofing material.This is necessary to prevent rotting of the wall section in contact with the foundation.

Construction of walls and roofs of houses from dry profiled timber

On the foundation fit double strapping. Bars on the lower crown are made of hardwood. This design carries the weight of the entire frame and transfers the load from it to the foundation.

On the first crown with a step width of not more than 70 cm lay floorboards. A 40x50 mm bar is attached to the logs, directly on which a rough floor is laid.

When the draft floor is laid, you can proceed to the construction of the main walls of the house. The timber is laid on each other and stapled with dowels. Between the bars laid insulation.

Chamber drying makes it possible not to caulk the walls, but many builders seal the joints of the bars for additional protection against humidity. Butt joints are made end-to-end, half-wood, warm corner.

After the erection of walls and partitions mount the roof. Rafter construction usually has a gable shape, optimal for most regions of our country. On the sheathing laid roofing material.This may be slate, metal profiled sheet, different types of tiles. It all depends on the desires and capabilities of the owner of the building.

If the design was built taking into account all the nuances, and the material was of high quality, with a low percentage of wood moisture, the shrinkage of the house will be minimal. Shrinkage of houses from the chamber drying beam with proper preparation of the material is not more than 3%.

Raw timber allows you to operate the house, insert windows and doors about a year after installation is completed. Chamber drying allows not to wait for such a period of time.

To eliminate the effects of minor shrinkage in the window and door openings, a wooden okosyachka is arranged.

Recommendations

A lot of houses are being built from the dry profiled bar of chamber drying at the moment. The combination of reasonable price qualities and excellent performance attracts a growing number of buyers. Reviews of such houses are mostly positive.

In the process of erecting a chamber drying beam, it is more convenient than other wood materials. You can carry out work on interior decoration and live in the house immediately after construction.

Due to the complexity of the technological process of chamber drying, the price of such a bar increases. However, its properties can save on thermal insulation, wood processing. The cost of construction in the end turns out to be small. In operation, such houses are quite economical.

Houses from a bar of chamber drying very warm. The ability to keep warm dry profiled timber allows you to save on heating in the cold season. This feature is noted by many owners.

The peculiarity of wooden houses is that they are capable of supporting natural air exchange. The coolness in the summer is kept inside for up to 4 days. The microclimate inside is very natural and comfortable for all inhabitants.

At the same time, all this applies to houses made of high-quality material. When choosing a material, you should pay attention to the flatness of the side surfaces of the profile. The lateral surface should be smooth, without knots, bark, evenly cut.

Important is the indicator of moisture bar, which should not exceed 18%. An expert opinion on the quality of the timber will help to avoid poor-quality or underdressed construction materials and the possible construction difficulties. The conclusion can be provided by the supplier of the material or an expert from the side.The moisture level of the lumber can be checked with a moisture meter. The timber must comply with GOST 8486-86 "Softwood lumber".

Frame houses from a bar are a fire-dangerous design. In this regard, you should be very careful about fire safety issues. Gas heating is extremely dangerous here. Special attention should be paid to electrical wiring.

The construction market today is very diverse. Many manufacturers offer ready-made kits for assembling a house frame, which includes walls, floors, ceilings, truss systems and all necessary mounting elements. Increasingly, consumers are choosing such home builders as prepared for installation. Buying a designer from a reliable manufacturer, you can be confident in the quality and reliability of the frame of the house offered for assembly.

For the construction of such a house is necessary a team of 6-8 people. Often the assembly is carried out without the hiring of specially trained people, the use of construction equipment is not needed here.

Beautiful examples

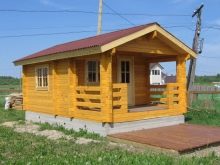

- The aesthetic component of houses of this type is very attractive. They are environmentally friendly, comfortable for residents.

- Finished houses look pretty nice. Two-storey houses with an attic differ spaciousness.

- Complicated tile roofing complements the composition of the house.

- The style of chalet houses today is very popular. The chamber drying beam shows itself in such houses very positively, it maintains the increased air humidity and keeps heat well. The appearance of the chalet - the personification of comfort and unity with nature.

About what tenology built houses of dry profiled timber, see the following video: